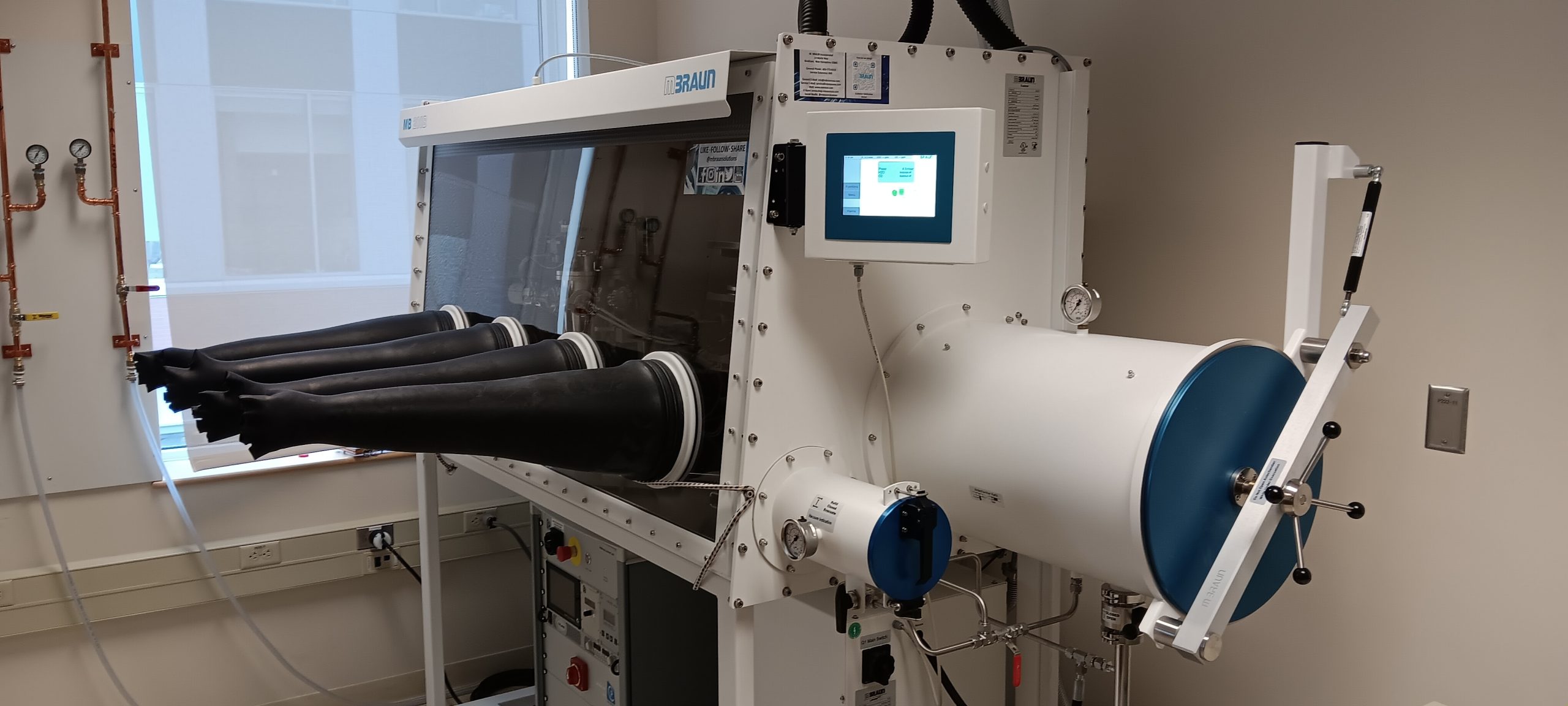

CORE Acquires New Glovebox Evaporator Setup

UMaine Coordinated Operating Research Entities (CORE) is pleased to announce the addition of a new resource to its array of Micro- and Nanofabrication Cleanroom equipment.

This glovebox evaporator was obtained as part of Assistant Professor of Electrical and Computer Engineering Dr. Taher Ghomian’s startup package, and is now managed for broad access by CORE out of Dr. Ghomian’s lab in the Engineering & Science Research Building (ESRB).

The MBraun MB200MOD glovebox evaporator, MiniVap thermal evaporator, and components provide an inert environment free of moisture and oxygen for a variety of chemistry, physics, and chemical engineering applications, including the fabrication of photovoltaics and batteries, solution processing, material deposition, and quantum dot semiconduction. This setup can accommodate sample sizes up to 1.5” x 1.5” and is suitable for Gold (Au), Aluminum (Al), Copper (Cu), Chromium (Cr), Zirconium (Zr), and Titanium (Ti) materials.

Micro- and Nanofabrication Cleanroom Research Facility Operational Specialist Henry Carfagno shares: “The biggest advantage of this system is that the deposition of materials via thermal evaporation can happen directly in the glovebox. Depositing materials using other tools is possible, and other glovebox systems likely exist on campus, but this setup allows the processing (wet chemistry) in an inert environment to go directly into thermal deposition without ever exposing the sample to the atmosphere.” Exposure to oxygen and moisture are the key issues being addressed by this acquisition.

The glovebox evaporator can be reserved for $23 per hour. Users will need to supply their own source materials and crucibles. Prior to reserving any CORE-managed equipment, users need to enroll in the university’s lab management system, Agilent iLab, and complete required safety and operational training.

To learn more, or to request a reservation, contact Micro- and Nanofabrication Cleanroom Research Facility Operational Specialist Henry Carfagno at henry.carfagno@maine.edu.