2017 Team 3 - Haptic Motion Floor Vemi Labs

About this Project:

Past Information:

This project is a carry over from last years capstone. To see the previous teams progress please visit their page HERE!

Brief Overview of whats done:

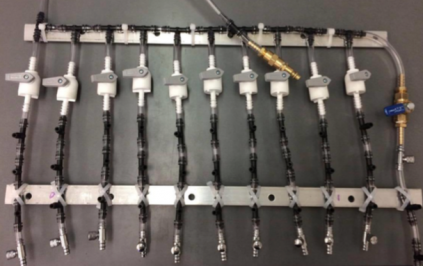

Vemi Labs has asked for help building a Haptic Floor. This is a floor that would be responsive and move based to the controls set in a virtual world. The idea is that the user would get a better immersive feel if the floor simulated what was going on in the display. Last years group made lots of progress but did not fully complete the project. See Figure 1 for a sample of how they setup air bag wedges and placed the hexagon pieces on top. Figure 2 show the valve system that they setup to add and remove pressure to the airbags.

What Needs to de done:

Vemi Lab explained that the main goal is the same that they want a haptic floor that can make the user feel like they are walking on a flat floor, through grass with a rock, and through mud. Ideally they need each section to be a separate system and be digitally controlled. They also what a better design for how the hexagonal tiles are put together. A past solution was tape.

OUR SPONSORS

Goodwin & Associates, LLC

Thank you to Goodwin Associates LLC (http://www.goodwinassociatesllc.com/) for helping support our project and helping us reach our goal on Kickstarter!

Oculus World

Big thank you! to Oculus world for sharing our Kickstarter on their and caring about our project. Without them this supporters like them this project would not be possible.

To view their article please click here.

Pneumatic Plus

Thank you to Pneumatic Plus for helping us with some of the hardware needed for this project.

Weekly Updates

Week 10/15/2016

This current week looked at the idea of replacing the hexagonal tiles with carbon fiber. The team also was granted access to move there project into the project room in the Machine Tool Lab. The team hopes to have the project there so they can start working on it sometime next week.

Week 10/22/2016

This past week we made contact with Vemi lab and picked the haptic floor so we could start working with it. Most of this week was spent doing research on what the team might want to change with the current floor design.

Week 10/29/2016

This past week the group looked at the idea of getting a raspberry pie to control the haptic floor. We are also in the process of designing a basic closed loop control system and will be testing a prototype.

Week 11/05/2016

This past week our group did some more research on control systems. With this they started learning how to program MatLab in hopes to use this for the haptic floor. For fundraising the team brainstormed ideas for give aways on the recent started kickstarter.

Week 11/12/2016

This past week our group put the final touches on the Kickstarter campaign, all that was left was to try and figure out the set goal. We also got the cost of your total project down by about $7000 dollars and ordered the raspberry pie to start testing out our design.

Week 11/19/2016

This past week our group got the approval to have our Kickstarter go live. We also took a look at the files we received from last years group including the solid work files. This helped us better understand how the old design was built.

Week 11/26/2016

Last week the team meet with the other advisor to try and get a different look on the project. During this conversation it was brought up that we may have an issue in the future of this project with making sure the tiles come down straight and don’t overlap. Some possible solutions are using magnets, springs, ties, and adhesive. It was discussed that this could help create a more 90 degree like structure. Doing this may make things like sidewalks possible. Our team agree that this is something that would need to be looked at and we would talk with VEMI labs to see it was outside the scope of our project.

Week 12/03/2016

Last week the team finally got in some of the parts ordered to start testing out the new design concept. Our team also moved the floor to one of our garages where we will be able to work on it easier. The rest of the week was spent trying to learn and understand the code needed to run the floor in matlab.

Week 01/28/2017

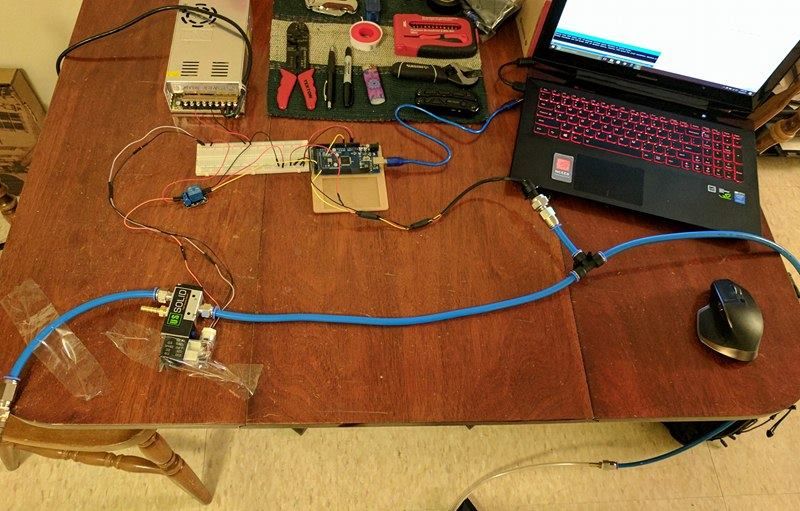

Wow have we been busy. Since break the team got some professional advice and changed from a using Raspberry Pi to an Arduino board due to the extra analog ports. The team has also looked at how we want the tiles to be supported when they are not being moved by the airbags. We decided that a honey comb type sell might offer the best support. We also have successfully figured out how to control the pressure transducer and have it display using the Arduino. In the next week we hope to get an airbag running in the system for further testing and try to design the honey comb design.

Week 02/04/2017

This week the team worked through some struggles with the programming. We tried the programming with 1 zone and it responded alright but not perfect. We decided that ordering a 5 way value might introduce a hold function on the bags allowing them to hold pressure better. We also ordered about $300 worth of supplies to try and get multiple zones working at once. Next week we plan on meeting with VEMI labs to discuss what we have and see what they think.

Testing Control System

Week 02/11/2017

This past week we meet with VEMI Labs and they were excited to see what progress we made. They also agreed that a 5 way value might be the better option. They talked to us about the concern of the pulsing in the floor for the pressure filling into the bag. We agreed that we would have to do some testing with adding rubber to reduce the feeling through the floor. Besides that they were pretty impressed.

02/18/2017

We have spent the last week lining up everything else that is left to do. We have put together a parts list and seem to be coming in right on budget. At the end of the week we ordered some more parts and hope to start working on how it will all be laid out inside the floor next week.

2/25/2017

At the beginning of the week we put two orders in for some more parts that are needed in the next phase of building. Some of the parts included the plugs needed for the 5 way valves, more 5 way valves, and stuff for needed for wiring. Later in the week the parts arrived and were picked up to be worked with next week. Also during this week more changes were made to the base to help prepare for future layout of the wires.

03/04/2017

This week are team came together and worked on getting some schematics laid out for the electrical system and for the pneumatic system. During this time we also made some changes to our schedule which has us fully testing the floor by the beginning of April. We also placed 2 more orders in this week to get all the other 5 way valves we need and some hardware to test all the sensors.

https://www.kickstarter.com/projects/1009863044/virtual-reality-terrain-simulator-university-of-ma

03/05/2017 - 03/18/2017

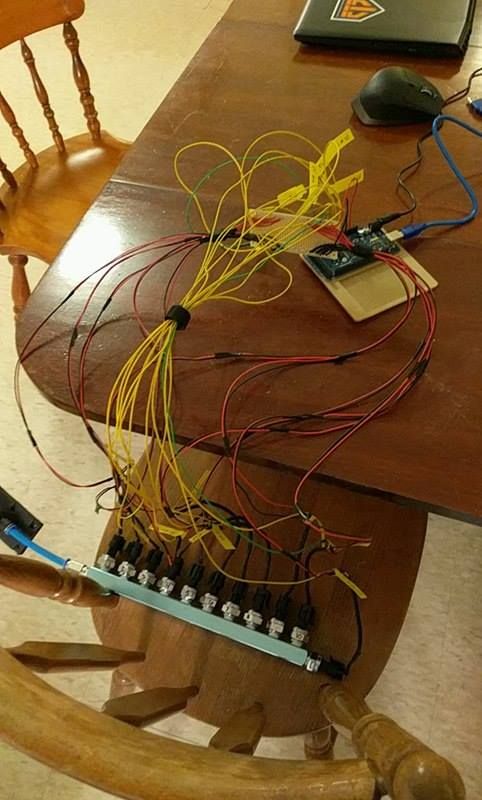

Over the two weeks of break the team has been working hard on getting the rest of the plans together. With some help from one of our professors we got through the code needed to move onto getting more than one zone setup. We also now have the Hexagonal shape modeled and ready to water jet. Once this is done it can be tested how well the airbags with the tiles will work. The team also made progress on how the 11 zones are going to be laid out. This was important so we do not have to move zones around now that they are being attached to the base. We have no received almost all the parts needed for the build. The first week back from break will be focused on testing out the hexagonal shape and getting the 11 zones wired.

03/25/2017

This past week we focused on trying to help our Kickstarted reach it’s goal. We are still short about $550 with less than a week to go. If we reach this goal it will allow us to put some additional funds into the project. Cody has also finished the code to run all 11 zones and we hope to test it out with the Hexagonal shape at the end of the week. It this goes smoothly and testing goes well we will be right on track to have a fully functional floor in the next 2 weeks. We also hope to show the client in the next coming week to see if we need to adjust or change anything before we put the final touches.

04/01/2017

This past week we completed and reached out Kickstarter Goal. We also made great progress on the floor and hope to have the prototype working by the end of next week. We also have made some more modification to the hexagonal piece to make sure that it will work with the airbags. Next week we hope to touch base with the client to show them the prototype and see what they might want changed.

04/08/2017

This past week we got the last of the work done needed for the wiring. We also got the prototype for the hexagonal piece in place. It was sized a little big so we will have to make adjustments before we make it out of fiberglass. Next week we plan to have pictures of the floor functioning and running.

04/15/2017

Our plans to have have the floor fully functional did not work out as planned. Once we trimmed the honeycomb piece down to size we realized that even at full inflation the lift achieved on each tile would be less then a half inch. This is not idea so we can up with a piston design made out of PVC pipes. This would add distance between the bad and the tile. With this we might be able to achieve a decent height. They other issue this caused was how to hold all the tiles together. After some analysis we decided to remake the tiles with holes so we could tie them together. In the next week we hope to test the piston idea out and get the final touches done.

04/22/2017

This past week we tried the piston idea on one air bag using a two part Epoxy to hold it to the the bag. After several tests which in evolved seeing how it handled under stress we concluded that this would be a viable solution to our problem. With this new design we were able to achieve a lift on each tile of close to 2 inches. This would be enough to simulate the functions they need. This that working we found out that our L-Channels are no longer high enough to support the height that the honeycomb needs to be placed at. We plan on ordering new L-channels and installing them at the end of the week. We also are in the process of making the honeycomb structure out of fiberglass. This will give the support we need.

04/25/2017

In the past couple of days we were able to get the L-Channels ordered and they should be here by Thursday. We also have the new honeycomb and tiles completed. Once the L-Channels come it we will be able to put the last pieces together. We also got all our electrical components ready to go into a Nema 1 rated box to protect them.

Our Team

Derek Dubois

Left: Derek is from Van Buren, ME and is Mechanical Engineering technology student that will be graduating in the spring. Derek plans to pursue an Masters in Business Administration following his graduation. In his spare time he focuses on his drone photography business.

Cody Sheltra

Middle: Cody grew up in Scarborough, Maine and is a senior in Mechanical Engineering Technology at the University of Maine. Some of his hobbies include snowboarding, weightlifting, and firearms. After college he hopes to be involved in mechanical engineering design with a successful company.

Tim Leblanc

Right: Tim is from Wells, Maine and is will be finishing up my MET degree this year and then plans to pursue his MBA. In his free time he runs a small junk removal business. When he finishes school he is planning on obtaining his MBA and hopes to start another business dealing with solar panel technology.