2015 TEAM 5

About the Project:

Team 5 is working on a project to develop a recorder for Nia within a year; so that she can learn to play starting in 3rd grade using one hand and her wiggle. We are currently in the research and prototyping phase of this project.

Team 5 would like to thank Professor Karen Horton for her time as our consulting P.E.

BILL OF MATERIALS: https://drive.google.com/file/d/0B9y6_bmfm9AubG15R2QyMTBjUU0/view?usp=sharing

PART DRAWINGS: https://drive.google.com/folderview?id=0BzVt2yvRD5UjfnF4SGRpM2hOTHE3bXd6N1pheXJ2YjdvMzJ4RVVwOUlMdld6X0tjLWdoUU0&usp=sharing

TEAM 5 Gantt Chart: https://drive.google.com/file/d/0B679KBtxPlAEZURhSXhGeFlzbE0/view?usp=sharing

Website Updates:

Update 20: (Maine Day Presentation)

Link to Final Presentation:

https://drive.google.com/open?id=0B8EJHcTO2WWWWFCOXdxUWdfSEE&authuser=0

Update 19:

https://docs.google.com/document/d/1qEGSM-it0tzZPQCd07qkxi4zfhQjow4g5QmgQ7U_2kI/edit?usp=sharing

We had to place our most recent update on Google drive as our website has reached hosting capacity.

Update 18: (March, 2015)

We have been exploring heavy modifications to our rotating sheath solution. Jacob ordered angel halo recorders, and we are updating our designs to work with this recorder. Nia has been learning with the Angel Halo thus far in class, we believe it might be an easier transition for her if an Angel Halo is used. Jacob has updated our bill of materials with parts we have ordered and made.

Pat has drafted CAD files of the Angel Halo recorder. He also preformed frequency analysis with Ian for the barrel solution.

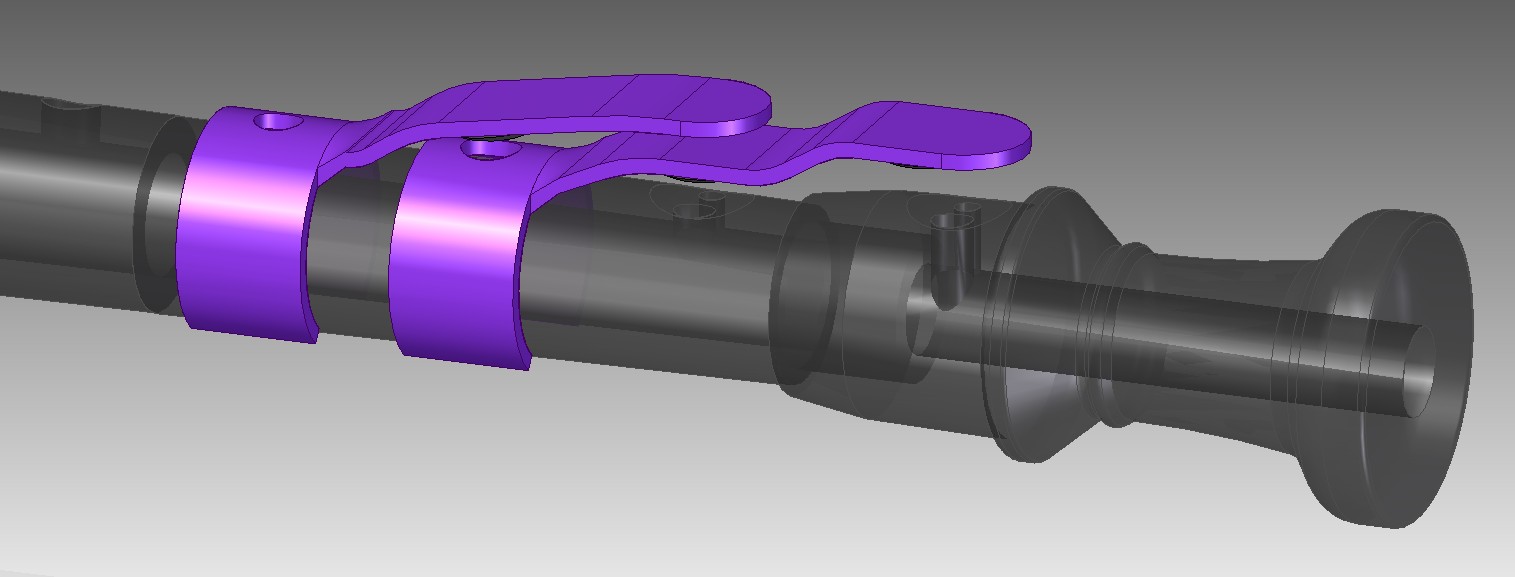

Ian had the idea to use multiple “barrels” that will each play a particular note that rotate to connect to the main recorder body. He drafted part files and we have printed several prototypes.

Ryan and Pat also looked into 2-part silicone for potential use for O-rings and potentially coating the inside of the older sheath solution for a better seal over the note holes.

AJ and Ryan drafted and printed NinjaFlex gaskets to seal between the end of the recorder and the barrels.

AJ has also been working an an alternative “Slide Whistle” solution, because of our ability to rapid prototype. AJ made plugs for the bottom holes of the recorder.

Leroy has been checking and dimensioning draft files for all the new parts. Which can be seen in the Part Drawings folder.

We have adapted a new solution that has rotating “barrels” that have a corresponding note associated with it. Nia will be able to change notes by rotating the adaption to change to the desired Note/Barrel.

Matt has continued working on the recorder brace and mount that Nia will use with our design. He met with Nia to mold the PolyFlex Brace to her forearm.

Ryan used an application from AutoDesk to capture a 3D model of the molded PolyFlex brace. It can be viewed here: http://www.123dapp.com/Catch/Poly-flex-brace/3771592 This was to see if we could create 3D assemblies with scanned parts.

Update 17 (14/Mar./2015)

MET Showcases Capstone at Engineering Expo in Gorham

Four teams represented MET today at the Engineering Expo at the University of Southern Maine in Gorham. MET was one of among dozens of tables representing companies and schools throughout Maine.

The Expo Team described the Capstone project to hundreds of parents, children and professional representatives about Nia and her need, the use of 3D printing to produce useful objects and the program as a whole.

The Team also gave away hundreds of 3D printed Space Invaders from the classic arcade game, and custom designed fidget rings that can be assembled and reassembled in a variety of styles and colors.

Update 16 (27/Feb./2015)

We met with Nia and her music teacher after school on Thursday 2/26.

We had representatives from other teams with us to observe how Nia has learned to play the recorder up to this point. We also wanted to look at the ergonomics of each teams designs. Below are some videos we took during our meeting.

NOTES FROM MEETING WITH NIA AND MUSIC TEACHER (Melissa Barton):

- Melissa said that students in her classes are taught to tongue every note and slurring on the recorder is not required or used.

- Nia said that she would like to play the flute in the future, but Melissa noted the whimsical manner of children, and that answer is subject to change.

- She once again, showed us the notes we need to play.

- Nia was able to use her pinky, look into a helpful solution.

- Wiggle subject to “break-outs” wears mitten regularly, able to spin sheath with some effort. She said that the sheath seemed a little heavy.

- She is already familiar with an Angel Halo recorder.

Update 15 (25/Feb./2015)

This week we printed two prototype sheath designs one sheath had an ABS shell, the other was a NinjaFlex sheath.

We are also meeting with Nia this week to get her input and gather data on how Nia already plays the recorder as well as how she might use our sheath.

Update 14 (20/Feb./2015)

Ryan, Matt and AJ did heat shrinkage test of TPE and ABS so we can more accurately size the part clearances. We found overall that shrinkage for both materials approximately -1.0% compared to expected sizes.

Jake was looking into relevant patent information for our designs and/or design process.

Matt is continuing to work on a recorder brace to help support the recorder.

Update 13 (13/Feb./2015)

AJ has made contact with Nia’s music teacher to schedule a meeting with Nia to test our sheath modification

Leroy put the sheath through the Dishwasher to make sure it could be cleaned without deformation due to heat.

Pat and Ian are going to perform full force and deflection testing of TPE.

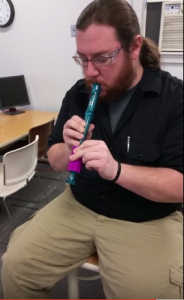

First test of recorder sheath documented video below:

Sheath Test 1 Video on YouTube

Update 12 (3/Feb./2015)

This week Matt and Ian met with Beth Johnson, OTR/L. Beth is an occupational therapist who specializes in hand and pediatric therapy. Matt and Ian brought with them a plaster casting of Nia’s wiggle for the therapist to look at while evaluating our design.

The team will be printing our own middle section of the recorder to test how it compares to a factory made one.

Update 11 (30/Jan./2015)

Our most current prototype of the sheath is ABS (Acrylonitrle Butadien Styrene) and TPE (Thermoplastic elastomer) printed together. The flexible TPE works well to seal the recorder holes, its also slides easily over the recorder; as we found in our friction tests. This allows for easy changing of notes. The ABS shell provides rigidity, it will be simple to use as Nia will be able to simply rotate the sheath to change notes.

The team has been doing significant amount of testing, there is a lack of data on 3D printed materials properties.

We have done testing and calculations for the coefficient of friction for ABS and NinjaFlex. The purpose of this is to calculate the force required to rotate the sheath about the recorder.

Thermoplastic Elastomer Info: http://www.glstpes.com/resources_faqs.php

Update 10 (16/Jan./2015)

We are now starting up again in our second semester of capstone. For our first week back we are reviewing and revising the team contract and schedules.

We have met with PE Karen Horton, who has agreed to advise us on our project. We will be performing standardized material testing with 3D printed ABS plastic with various infills to derive a yield strength for it.

Our team is going to be producing plaster castings of Nia’s wiggle from a mold provided by EMMC Prosthetics, these castings will be distributed to all of the teams for use in human factors, and compatibility.

Update 9 (05/Dec. – 10/Dec/2014)

The team has been working on the sheath (updated from Sleeve solution), and Pringle Solution. Updated Solid Edge files for some of the designs.

We have been looking further into materials for hole covers and have recently started working with “Ninja Flex”, a polyurethane thermo plastic that can be 3D printed. The finished product is both strong and flexible making an ideal material to cover holes. It also can be used to make gaskets and O-rings quickly and to any size we may require. AJ put in quite a bit of time getting our 3D printer configured to print the Ninja Flex. Ryan did some research on how to design the note hole cover pads which will be attached to the bottom of the pistons in our “Pringle” design.

Matt printed his first mockup of the recorder holder, which features a snap fit brace which will be supported by two yokes which will be adapted to an existing Harmonica holder. The purpose of this is to take some of the supporting load off Nia, and provide stability. With this she will be able to use her hand and her wiggle together to play the recorder without concern of dropping it.

Jacob did a cost analysis for the materials we are using for each 3D printed parts. As well as compiling the costs associated with the adapted harmonica brace. He is also working on a bill of materials for where we currently stand.

Ian has continued working on updating the sheath design. Shown here:

The team has decided that we want to adapt both of our current designs to work with the bottom 4 holes of the recorder rather than the current 3.

Here is a time lapse video of our 3D printer (MakerBot) printing the yokes for the recorder support. This print took approximately two hours real time.

During the week of December 7th, the team worked together to create our Final Presentation for this semester. We presented to the class our current and past concepts, as well as shared our development processes.

This will be the last update for this semester. Updates will resume after winter break.

Our final presentation for the semester:

Update 8 (25/Nov/2014)

The team has made the decision to abandon the proposed slide whistle design, and move on with the sleeve, and “Pringle” design.

Pat made some modifications to the design in now includes spring pistons as a method to cover the holes.

AJ, Leroy, and Pat have done some frequency analysis of the recorder while trying to find a good candidate material for a hole cover. We tested cork, foam, and vinyl. Each of these drastically changed the note. We tested the notes using their frequency’s with a program called Spectrum View.

The team is working hard doing material research and calculations for ABS plastics. ABS is our primary 3D printed material for the recorder.

AJ built and calibrated a spring pressure gauge for calculating the force needed to seal the recorder hole in order to get the correct note.

Matt finished Solid Edge assembly and part files for a potential recorder holder, and did beam calculations for the design.

Jake compiled information to calculate associated cost.

Update 7 (17/Nov/2014)

After log books were due last week the group did a lot of research and analysis on the our projects. We also acquired two more recorders.

Ian and Leroy are working on a set of fully dimensioned parts for the recorder, as well as for the modifications. Matt is working on a neck strap.

Ryan researched 3D printed snap fits of plastics; AJ and Pat printed off a few of these seen below.

AJ and Pat looked into printing surface properties of ABS plastic when Printing at 100 μm , and at 200 μm . They printed two identical ABS cubes with the 3D printer, the only difference was one was printed at 100 μm the other at 200 μm; it is important to note printing at 200 microns talks roughly half the time to print as 100 μm.

Pat, AJ, and Jake brought these to Kelly Edwards in Murray hall to examine them more closely.

Matt researched cleaning and sanitation of the recorder, and with our new information on surfacing we have concluded that 100 μm will be better for that reason.

Update 6 (04/Nov/2014)

AJ fixed the MakerBot and printed two design prototypes. In purple ABS plastics as requested by Nia. AJ worked on finalizing purchasing requests.

Matt analysed Nia’s range of motion of her wiggle using the video we recorded when we met her.

Ian was tasked with creating drawings and a mock up of a PVC sleeve solution. Ian also worked on updating Gannt chart.

Pat and AJ worked on the “Pringles” design and mock up. (C-shaped note hole cover)

Ryan worked on the webpage, and started looking into a sleeve bearing solution.

Jacob researched standard parts and concluded that thumb screws could be a good solution.

Update 5 (26/Oct/2014)

This week was full of setbacks, as the prototyping machine team 5 is using had technical issues and is in need of repair.

AJ was tasked with doing a microscopic analysis of printed layers, only to have the Makerbot fail later the day before the samples could be printed. He then spent the next 3 days diagnosing the problems and getting parts to repair the device.

Matt, Jake and Ryan worked on potential harness solutions and mounting options for Nia. Chief on our list is a modification of a harmonica strap which will solve both weight and fingering problems, allowing Nia to focus on the modification for her Wiggle. It will also blend well with the other students (who have neck straps on their recorders).

Pat proceeded to pursue past patents and pending patents pertinent to the project for potential problems in preparing potential modifications.

Leroy and Ian continued work on the sleeve style solution. The biggest problems now are figuring out how to close the holes and still be able to spin the sleeve.

The team is expecting to have some mockups ready next week

Update 4 (17/Oct/2014)

Team met with Joel to discuss the logbook.

Leroy and Ian begin early concept ideas and sketches for possible adapter.

Pat is looking into relevant patents.

Jake and Matt look into possible recorder supports.

Update 3 (10/Oct/2014)

We turned in our 1st logbook on Oct. 8 We will review it next week with Joel

- Ian designed team logo for webpage. He also created the group Gannt chart.

- Pat finished Solid Edge parasolid of recorder base.

- AJ researched materials adapter as well as safety information.

- Jake and Matt looked into prior Art.

The team has been meeting regularly to update the logbook and to discuss potential ideas and overview group members independent research/benchmarks.

Update 2 (03/Oct/2014)

Team 5 has had a solid 10 days getting the paperwork in order for the entire project.

- Jake looked into one handed recorders for Nia (update: this has been ruled out as Nia wants to use her Wiggle)

- Ian and Leroy put some time into migrating data to a more user-friendly source via Google Drive.

- Ryan put a lot of groundwork necessary to regularly update the website.

- Pat and AJ were selected to learn the recorder (again) to better assist in building an adapter for Nia.

- Matt began work on protecting any potentially patentable ideas the team comes up with.

Overall a very busy week for the team, with the competition and project criteria being solidified at the top of the chain, next week should be significantly more interesting.

Update 1 (26/Sep/2014)

With teams established, the entire class met with Nia Nicola on Wednesday to discuss her needs in playing a recorder. She mentioned that she would want to play flute later so we’re taking that into consideration in our design, even though we won’t be here when that comes around. Many measurements were taken by various members of the class, from her height to sitting length, arm length and various circumferences of her wiggle up to her elbow. Nia was an exceptionally good sport about the whole thing. Collectively, the team expects good things to come out of this, both as a Team and as a class.

TEAM BIO’s:

AJ Rutherford is a Veteran of the U.S. Army, Computer Systems Technician, father of two and non-traditional student at UMaine. Specializing his degree in manufacturing, AJ has spearheaded a movement within MET to bring Rapid Prototyping/3D printing into the core cirriculum for future students. He also currently assists junior level student in a formal capacity as a Teaching Assistant and informally for other student clubs and organizations. AJ’s hobbies include target shooting and archery, gaming, woodworking and assisting his son in activities related to the Boy Scouts of America. https://www.linkedin.com/pub/aj-rutherford/a5/17b/786<.

Ian Black– Ian grew up in Biddeford, ME where he continues to work in the Lobstering industry during the summer. With an introduction to Engineering and Manufacturing during his high school years at Marca Coating Technology in Gorham, ME, he was drawn to pursue engineering. During his time at UMaine he has played Club Baseball and been a member in the student chapter of Engineers without Borders. http://www.linkedin.com/pub/ian-black/80/637/363

Jacob O’Jala is from Morrill, Maine. Jacob enjoys Hunting and Fishing. He plans to work and live in Mid coast Maine as a Mechanical engineering after graduation.

Leroy Wallace is from Quincy, Massachusetts. He enjoys playing baseball, hockey, and football. He is also an apprentice plumber. Leroy plans to work in the aviation engineering field upon graduation.

Patrick Leary grew up working on his family’s dairy farm in Saco, Maine. In school he discovered a passion for math and science, and growing up around the farm gave him a mechanical understanding, so he enrolled in the MET program at UMaine. His free time is spent adventuring outdoors, playing pickup basketball, and going back to the farm to help out. He has enjoyed all areas of study at the University, and hopes to pursuit a career in an HVAC or manufacturing environment. http://www.linkedin.com/pub/patrick-leary/a5/317/974/

Matt Strickrott is a 23 year old Senior from Gilford NH. Born in Gainesville FL. He played and now works for the D1 Mens Hockey team here at UMaine. He loves riding motorcycles and hopes to one day design alternative energies in the automotive energies.

Ryan Ross is from Kennebunk, Maine. He is majoring in Mechanical Engineering Technology and minoring in Electrical Engineering Technology. Ryan became interested in engineering through his participation in International Bacceloriate programs in math,physics, and biology during high school. As well as his intrerest in the automotive field. He hopes to work in automotive or military hardware design after graduating.