Using 3D Printing to Expand Access to eDNA Research

By Evan Bartow, Writing Intern

For some researchers, environmental DNA (eDNA) based research is limited and underutilized due to its, at least perceived, cost and ease of use. A major part of the NSF EPSCoR RII Track-1 Maine-eDNA grant is focused on the development and creation of advanced eDNA collection technologies and strategies. As eDNA continues to develop as a research tool, it is essential that researchers have the most advanced technologies and techniques available.

To help further this effort, Maine-eDNA awarded a Commercialization and Research Seed Grant to University of Maine (UMaine) Assistant Professor of Aquatic Genetics Erin Grey in collaboration with Manomet and the Department of Fisheries and Oceans Canada. The goal of this project is to reduce barriers currently limiting eDNA adoption through various avenues, one avenue being the development of affordable automated eDNA samplers. This is where Aaron Snow, an undergraduate mechanical engineering student at UMaine, enters the picture.

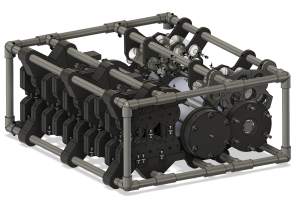

Connecting through the 3D Printing Club at UMaine, Snow explained that Grey was “looking for someone with the abilities and skills necessary to 3D print and manufacture the components required for the SASe V2 (subsurface automated sampler for eDNA).” These open-source devices make it easy to conduct repeat field sampling at spatial and temporal scales and importantly, are designed to be customized to meet the varying needs of researchers as projects and advancements require.

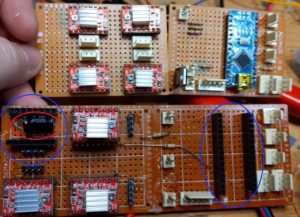

With a background in design and 3D printing, Snow set out to replicate the design of previous automated eDNA samplers. While replicating the SASe V2’s already price-conscious design, Snow discovered the potential for improvements to further reduce the repair costs and increase the functionality of these devices. Looking to expand the current capabilities of automated eDNA collectors, Snow developed a new device that is easier to use and more diverse in its functionality, while staying competitive with other current models.

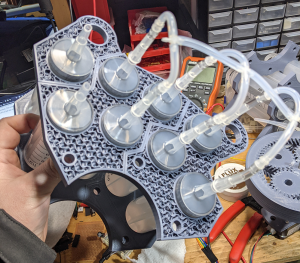

When developing these new devices, Snow focused on creating collectors that are “open sourced, cheap to fix, and easy to repair.” For eDNA researchers there are a few pressures when it comes to current models. The devices can be limited in use due to cost of parts and small collection capacities. By containing primarily 3D printed parts, Snow’s devices can be built by other researchers that have access to a 3D printer. Staying true to the mission of making these devices accessible, Snow’s automated eDNA collectors remain open-source. This means that researchers can modify the build and edit the code of the firmware in these devices and program their operation however best fits their needs.

Snow explained the design could be deployed in different water source locations with the capabilities to withstand Arctic temperatures. One specific feature that sets these devices apart from other automated eDNA collectors is the device’s 60 collection cartridges. This expanded capacity allows researchers to collect more samples than previously possible with other devices currently available.

Currently in the building stages of the project, Snow plans to have a fully assembled prototype by the end of May. Looking towards the future, Snow hopes to turn the creation of these devices into a small business where he will develop models and act as a consultant to other organizations. Due to his work in creating new automated eDNA collection devices, Snow has further advanced the capabilities of eDNA researchers.