NSF awards $6 million for UMaine-led effort to establish new lab to study AI in advanced manufacturing

A new lab to study how the latest artificial intelligence tools and techniques could bolster advanced manufacturing in northern New England will be launched with a $6 million award from the National Science Foundation to the University of Maine.

UMaine will collaborate with the University of New Hampshire, University of Vermont, Southern Maine Community College, Dartmouth College and Vermont Technical College to create the Northeast Integrated Intelligent Manufacturing Lab (NIIM), funded by a Research Infrastructure Improvement Track-2 Focused EPSCoR Collaboration award.

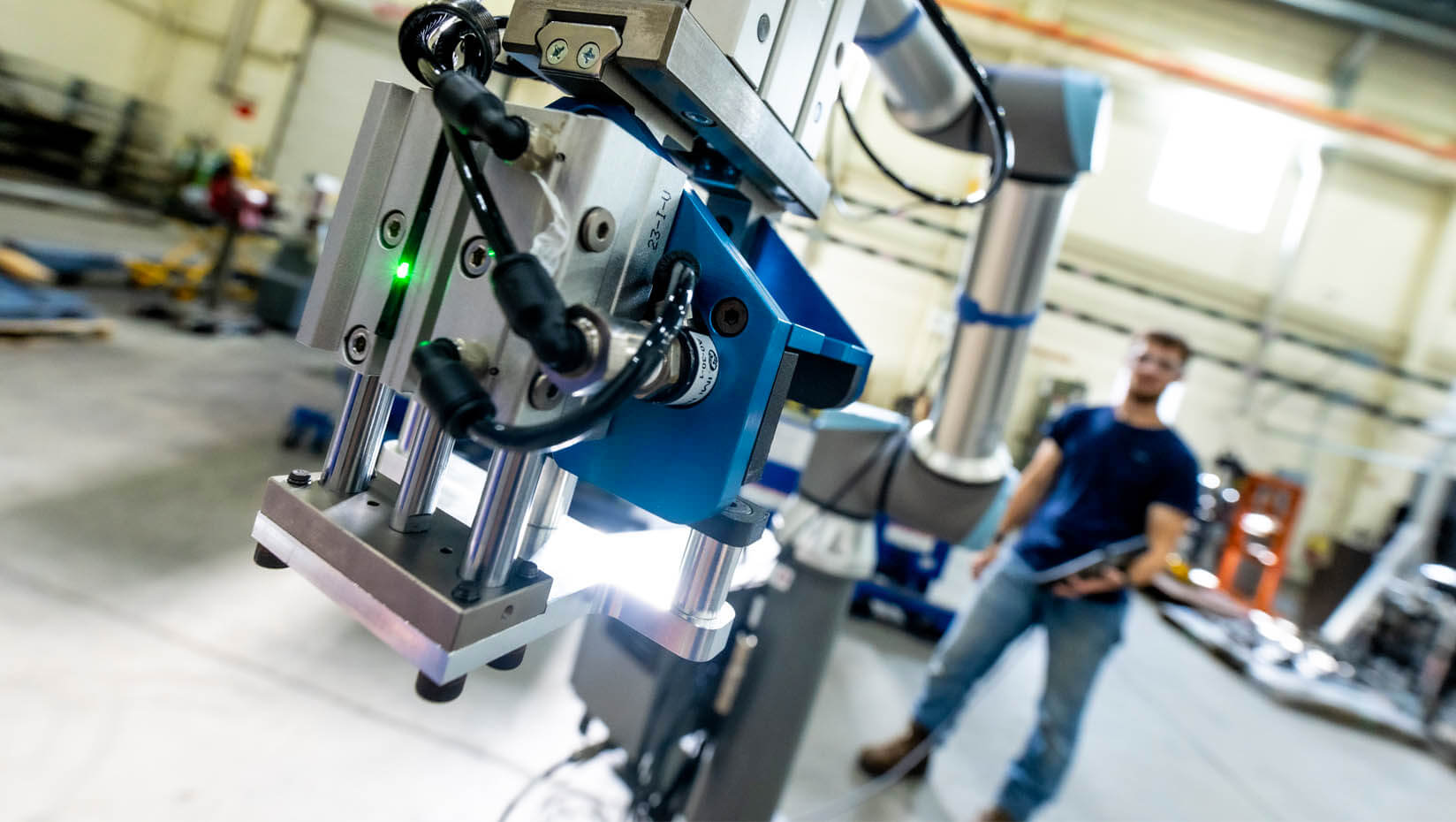

The lab, based at UMaine, will be used to investigate new technologies to increase advanced manufacturing efficiency, scalability, capability and safety by incorporating AI, robotics and 3D metal printing.

The research team behind the lab will explore the efficacy of various AI techniques for advanced manufacturing, including interpretable machine learning models, physics-guided and multitask learning, and unsupervised domain adaptation. In collaboration with industry partners, researchers plan to develop new AI models for advanced manufacturing that are more interpretable and adaptable, AI-guided design for additive metal manufacturing that reduces unnecessary trial-and-error, self-aware computer numerical control machines for subtractive manufacturing and industrial robots to support cellular manufacturing.

Through these studies, the lab and its scientists aim to help northern New England manufacturers evolve their businesses by providing research, education and workforce development. For example, researchers could devise learning techniques that factory workers could use to teach their robots new skills.

“This is an example of the interdisciplinary innovation and partnership that an R1 research university provides,” says UMaine President Joan Ferrini-Mundy. “UMaine has long led advanced manufacturing research and development that helps to impact economic development. This award builds on those efforts to support a manufacturing industry in transition for the future and continues UMaine’s nationally recognized leadership in innovation.”

Yifeng Zhu, UMaine Libbey Professor of Electrical and Computer Engineering, is leading the project alongside co-principal investigators Chaofan Chen, UMaine assistant professor of computer science; Brett Ellis, UMaine associate professor of mechanical engineering technology; Se Young Yoon, UNH associate professor of electrical and computer engineering; and Nick Cheney, UVM assistant professor of computer science.

Other UMaine researchers involved in the project include Liping Yu, assistant professor of physics; Vikas Dhiman, assistant professor of electrical and computer engineering; John Belding, director of the Advanced Manufacturing Center; Bruce Segee, professor of electrical and computer engineering; Todd Gabe, professor of economics; Andrew Crawley, assistant professor of regional economic development; Rebecca Colannino, director of Upward Bound; and Matthew Dube, an aspirations instructor and research mentor for UMaine’s Upward Bound and an assistant professor of computer information systems appointed at the University of Maine at Augusta.

“The brilliant faculty and students at the University of Maine are conducting cutting-edge research and making promising discoveries in a wide variety of fields,” said Sens. Susan Collins and Angus King in a joint statement. “This funding will help UMaine continue to build on its groundbreaking achievements that are powering our economy today and into the future. We welcome this investment that will support Maine businesses, help create good jobs in our state, and solidify UMaine’s leadership in advanced manufacturing research.”

Infusing artificial intelligence into manufacturing can bring a lot of benefits to business, says Zhu. “We will actively work with local manufacturers to build prototype test beds to evaluate and deploy our AI-powered technologies.”

Maine industry is extremely eager to be able to use advanced Industry 4.0 technologies to improve manufacturing productivity, says Belding. “All of the work AMC is completing with Maine companies involve automation, robotics, multi-axis machining, laser machining and metal additive manufacturing. Having AI as another tool in the toolbox allows us to cover even more of Maine industry needs,” he says.

John Murray, director of business development for Progress Engineering, says his Manchester, Maine-based company “is excited at the prospect of working with the University of Maine on using AI programs on several known applications in the forest products industry here in our state.

“We congratulate UMaine on receiving this AI development grant,” Murray says. “Progress Engineering envisions this being a huge benefit to the wood products industry as it applies to development of cost-effective, automatic wood grading systems for our smaller companies.”

“Yale Cordage needs to continuously ensure the top quality we are known for in each rope we produce,” says Glenn Jameson, director of design and development for Yale Cordage in Saco, Maine. “We would like to make this inspection process more robust. We believe advanced technologies such as AI and cameras can help us achieve this goal to add leading-edge production and jobs to our growth in the state of Maine.”

NIIM will utilize research infrastructure, community partnerships, faculty expertise and other existing investments across the participating institutions to support the project, including the UMaine Advanced Research Computing, Security, and Information Management (ARCSIM). The team at ARCSIM will work with Segee to launch federated supercomputing resources in Maine, New Hampshire and Vermont.

“For this project, UMaine ARCSIM is enabling senior research personnel by ensuring adequate access to high-performance computational resources,” says Shane Moeykens, director of ARCSIM and Maine EPSCoR. ARCSIM supports the research computing needs of the university research community and its collaborators, and is associated with Coordinated Operating Research Entities (CORE), which is overseen by the Office of the Vice President for Research and Dean of the Graduate School.

To ensure the lab provides tools and knowledge that are relevant to the priorities of the northern New England manufacturing sector, the team will collaborate with manufacturing extension partnership programs (MEPs) in the three states, an industrial advisory board, industry partners, and the U.S. Economic Development Administration University Center for Economic Development.

Funding from the award will allow the team to recruit a postdoctoral associate and other professionals, graduate and undergraduate student researchers; and purchase a collaborative robot, 3D metal printing and other advanced manufacturing materials.

The lab and the research it generates also will yield new educational materials for UMaine’s Upward Bound program, which provides opportunities to low-income high school students that help prepare them for college; UNH’s Northeast Passage, which supports disabled students and workers at community and technical colleges; and community colleges across the three northern New England states.

Contact: Marcus Wolf, 207.581.3721; marcus.wolf@maine.edu