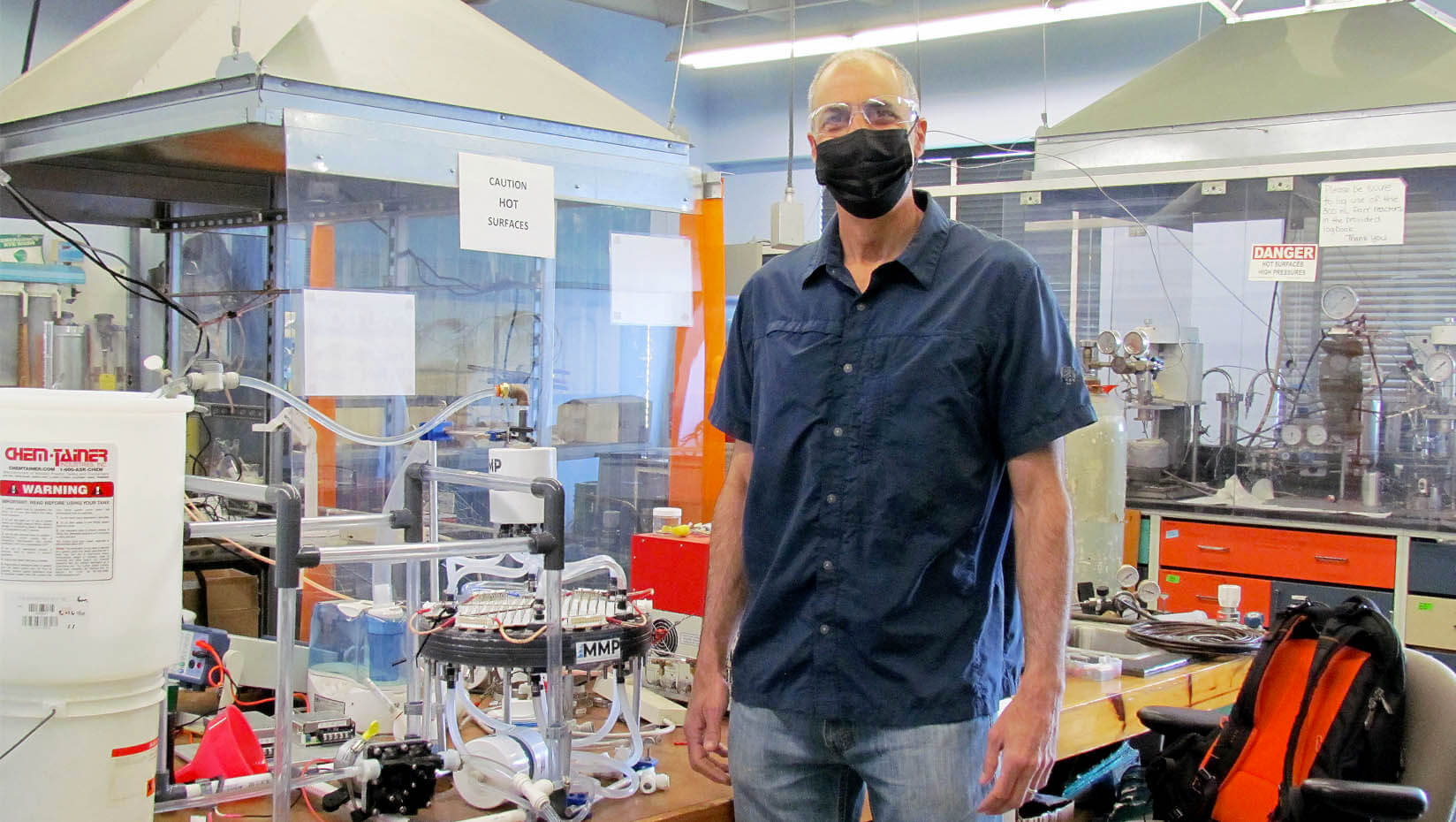

DeSisto receives EDA award to help boost local production of environmentally friendly disinfectant

In the spring of 2020, University of Maine professor of chemical and biomedical engineering William DeSisto, like a lot of people, thought more about disinfectant than he ever had previously. And not just about disinfectant itself, but also about where it comes from.

When hospitals were facing urgent shortages of hand sanitizer early in the pandemic, DeSisto was part of the team that established UMaine’s hand sanitizer production operation, which, with the help of statewide partners, ultimately supplied more than 3,000 gallons of hand sanitizer to Maine health care facilities.

“That experience taught me a lot about the vulnerability of the medical supply chain and how important local production can be,” says DeSisto.

Now, DeSisto is working with Maine manufacturing and other partners to refine technology that could increase local production of an environmentally friendly bleach alternative made from only salt, water and electricity.

The substance, hypochlorous acid, is safe, nontoxic, and can be 70–80 times more effective than bleach. It has been identified by the U.S. Environmental Protection Agency as an effective disinfectant against SARS-CoV-2. In addition to surface disinfection, hypochlorous acid can be used to fog building interiors to capture and remove suspended aerosolized virus particles. The base technology to produce hypochlorous acid has been around for some time, and DeSisto is researching new production concepts aimed at improving reliability and economics for local production. His work was recently awarded $374,752 by the U.S. Economic Development Administration (EDA) utilizing CARES Act funding for economic development assistance programs to help communities prevent, prepare for, and respond to coronavirus.

“Because of its effectiveness at low concentration and its nontoxicity, hypochlorous acid has great potential,” says DeSisto. “It’s a versatile product that can be used in a wide range of applications — medical settings, hospitality, agriculture, even wastewater treatment — but it has a relatively short shelf life, hence the value of developing local production infrastructure. Creating capacity to produce hypochlorous acid in Maine could really expand market opportunities for this type of disinfectant and reduce risk from supply chain interruptions like the ones we saw early in the COVID-19 pandemic, particularly for rural areas.”

The production method is based on electrolysis — that is, a direct current is used to initiate the chemical reaction. DeSisto is exploring a variety of different approaches. Partners include Biddeford-based Maine Manufacturing Partners, as well as several municipal wastewater treatment facilities.

Contact: Ashley Forbes, ashley.forbes@maine.edu