New $20 million additive manufacturing initiative connects local economies with national lab, UMaine resources

A new research collaboration between the University of Maine Advanced Structures and Composites Center and the Department of Energy’s Oak Ridge National Laboratory (ORNL) will advance efforts to 3D print with wood products, creating a new market for Maine’s forest products industry.

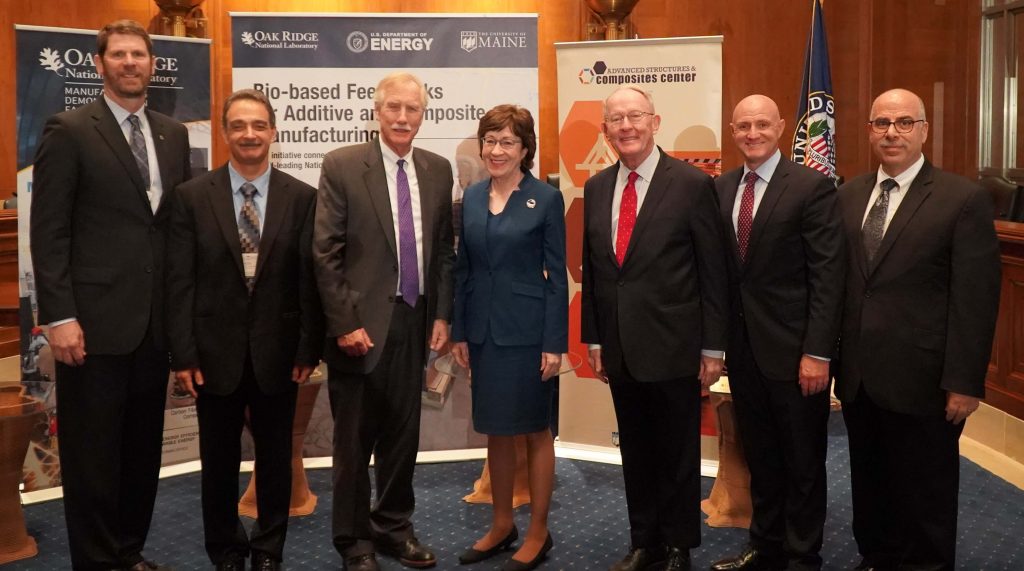

U.S. Sens. Susan Collins, Lamar Alexander and Angus King joined Daniel Simmons, assistant secretary for energy efficiency and renewable energy at the U.S. Department of Energy, as well as leaders from UMaine and ORNL in Washington, D.C., May 2 to announce the launch of the large-scale, bio-based additive manufacturing program.

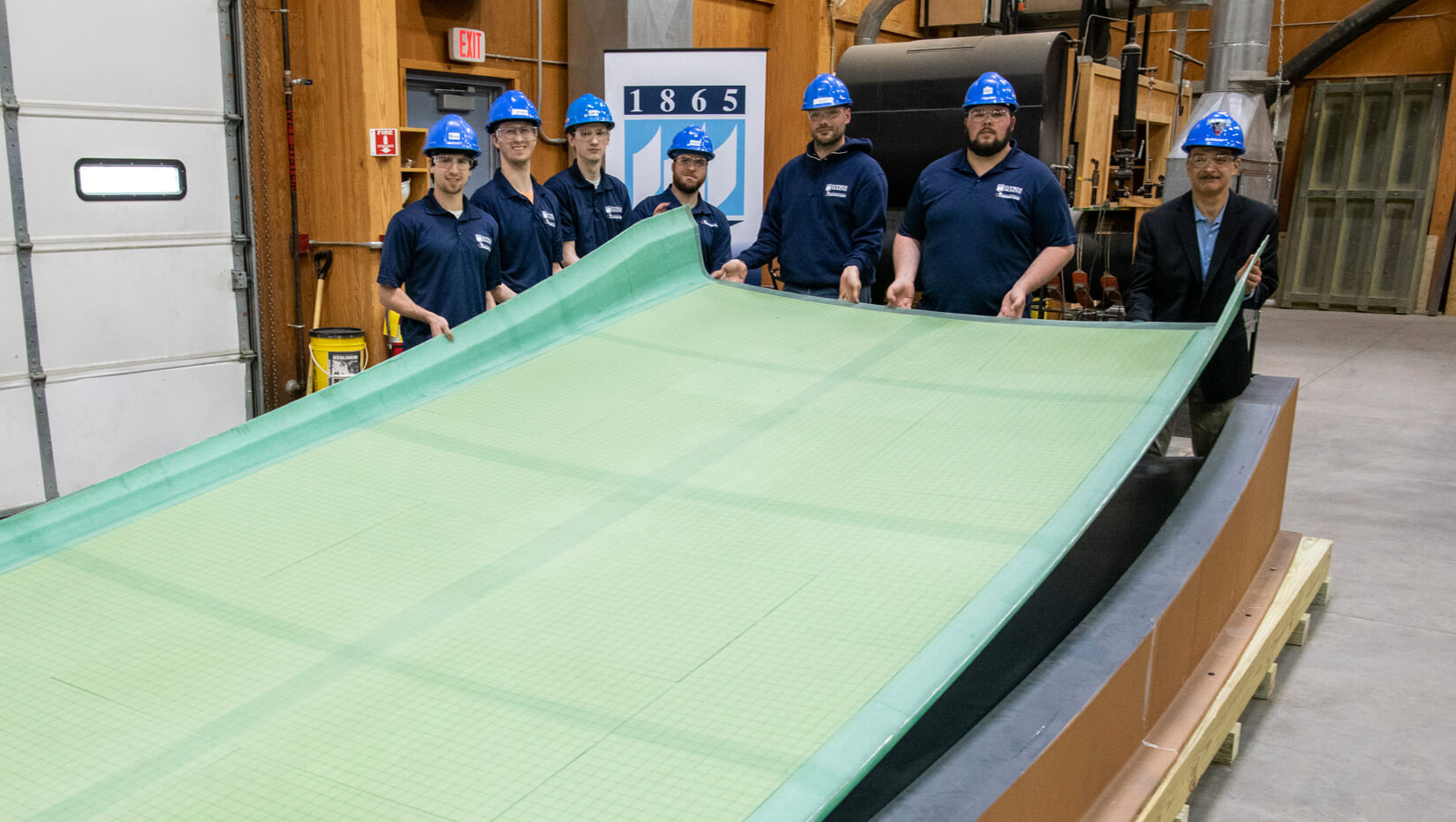

The ORNL and UMaine research team will work with the forest products industry to produce new bio-based materials that will be conducive to 3D printing a variety of products, such as boat hull molds, shelters, building components, tooling for composites and wind blades. They also will position the industry to print large, structurally demanding systems, such as boats.

“This exciting initiative is a win-win that will bolster the cutting-edge research performed at the University of Maine as well as support job creation in our state,” said Collins. “The development of sustainable, inexpensive wood-based materials for large-scale 3D printing has the potential to invigorate Maine’s forest products industry. This project is an outstanding example of our national labs working cooperatively with universities to drive American innovation and strengthen our economy.”

“Using Maine forest products for 3D printing is a great way to create new jobs in Maine and a good reminder that national laboratories are our secret weapons in helping the United States stay competitive in the rapidly changing world economy,” said Alexander. “The partnership between the University of Maine and the Oak Ridge National Laboratory is a model for how science and technology can help Americans prosper in the new economy.”

“Maine’s forest products industry is central to our state’s identity, and plays a leading role in our economy, which is why bringing innovation and creativity to the Maine woods is so important,” King said. “I can think of no partnership more capable of advancing the industry than the world-class research institutions at University of Maine and Oak Ridge National Laboratory. With their collaborative expertise, Maine can leverage new opportunities to attract bio-based industries to our state, further cutting-edge ideas, and foster growth and prosperity in our state’s rural communities.”

The $20 million effort, funded by DOE’s Advanced Manufacturing Office, aims to strengthen regional manufacturing by connecting university–industry clusters with DOE’s Manufacturing Demonstration Facility (MDF) at ORNL, said Daniel Simmons, assistant secretary in the DOE Office of Energy Efficiency and Renewable Energy.

Alexander, chairman of the Energy and Water Development Appropriations Subcommittee, and Collins, a member of the subcommittee, worked to secure funding for the initiative in the fiscal year 2019 Energy and Water bill. MDF will enable regional industries to apply decades of experience in a short period of time to more effectively translate additive manufacturing technology to the region’s strengths.

Collins and King have been active in encouraging this type of collaboration between Maine’s forest products industry and leading researchers. In 2016, the senators called on the U.S. Department of Commerce to establish the Economic Development Assessment Team (EDAT) that would work across agencies and sectors to create strategies for job growth and economic development in Maine’s rural communities. The work of the EDAT led directly to this partnership between UMaine and ORNL.

The new partnership links two world-class research centers, said UMaine President Joan Ferrini-Mundy.

“This collaboration is a shining example of UMaine’s commitment to exceptional research, workforce development, and economic advancement benefiting Maine and beyond. This partnership will allow our faculty and students to work seamlessly with Oak Ridge researchers, learn, innovate and strengthen local manufacturing,” Ferrini-Mundy said.

ORNL is a world leader in advanced manufacturing and is DOE’s largest science and energy laboratory, conducting basic and applied research to deliver transformative solutions to compelling problems in energy and security. UMaine is a world leader in cellulose nano fiber (CNF) technology, including development of nano- and micro-cellulose reinforced thermoplastic composites through its Advanced Structures and Composites Center.

“The University of Maine is doing cutting-edge research related to bio-feedstocks and the application of advanced manufacturing in regional industries. We are thrilled at this opportunity to expand our research base while providing UMaine with access to the leading national capabilities we have developed at ORNL’s Manufacturing Demonstration Facility,” said Thomas Zacharia, director of Oak Ridge National Laboratory.

“Our state’s forest products industry is not only adapting to succeed in today’s global economy, but it is on the vanguard of some of the nation’s most innovative advanced manufacturing efforts,” said Maine Gov. Janet Mills. “With this partnership between the University of Maine and Oak Ridge National Laboratory, our state will continue to drive critical innovation in the bioeconomy that will help create jobs and revitalize rural Maine. I applaud the U.S. Department of Energy, the University of Maine, and our congressional delegation on this achievement, and pledge the assistance of my administration as we work to build a prosperous state.”

The collaboration will provide students, faculty and companies associated with UMaine’s Advanced Structures and Composites Center access to ORNL’s assets and expertise in advanced manufacturing. ORNL researchers, in turn, will gain access to UMaine’s facilities and expertise in CNF and composites.

Scientists from ORNL and UMaine will conduct fundamental research in several key technical areas, including CNF production, drying, functionalization, and compounding with thermoplastics, multiscale modeling and sustainability life-cycle analysis. By placing CNF into plastics, strong, stiff and recyclable bio-derived material systems can be developed that may be 3D printed at deposition rates of hundreds of pounds per hour and up to 50 percent cellulose fiber loading. Printing with 50 percent wood promises to open new markets for the pulp, paper and forest products industries.

As a forest product, CNF could rival steel properties, and its successful incorporation into plastics shows great promise for a renewable feedstock suitable for additive manufacturing.

Habib Dagher, executive director of UMaine’s Advanced Structures and Composites Center, characterized the initiative as being like “putting together the NBA All-Star team for massive 3D printing with wood.”

“We will integrate 20 years of research in bio-based composites at UMaine and 3D printing at ORNL,” Dagher said. “It is an opportunity engine for our students, faculty, staff and manufacturing industry who will work side by side with researchers at our nation’s foremost research laboratory. Together, we will break down wood to its nanocellulose structure, combine it with bioplastics, and print with it at hundreds of pounds an hour. The research we will be conducting with ORNL will spur next-generation manufacturing technologies using recyclable, bio-based, cost-effective materials that will bolster our region’s economy.”

Dagher thanked Collins, King and Alexander for their leadership, and DOE for its award to the competitively funded proposal.

Video of the May 2 announcement is online.

Contact: Meghan Collins, 207.581.2117; mc@maine.edu