Tajvidi awarded $250,000 to develop next-generation CNF floor, wall products

Mehdi Tajvidi knows that big things can come in small packages.

He works with cellulose nanofibrils (CNF) — the natural structural building units of wood that are 1/100,000th the width of a human hair.

The University of Maine assistant professor of renewable nanomaterials describes CNF as magical. The renewable biodegradable material has superior properties, he says, including exceptional strength and ability to bond.

Tajvidi has been awarded $250,000 from P3Nano — a public-private partnership founded by the U.S. Endowment for Forestry and Communities and the U.S. Forest Service — to develop next-generation CNF building materials.

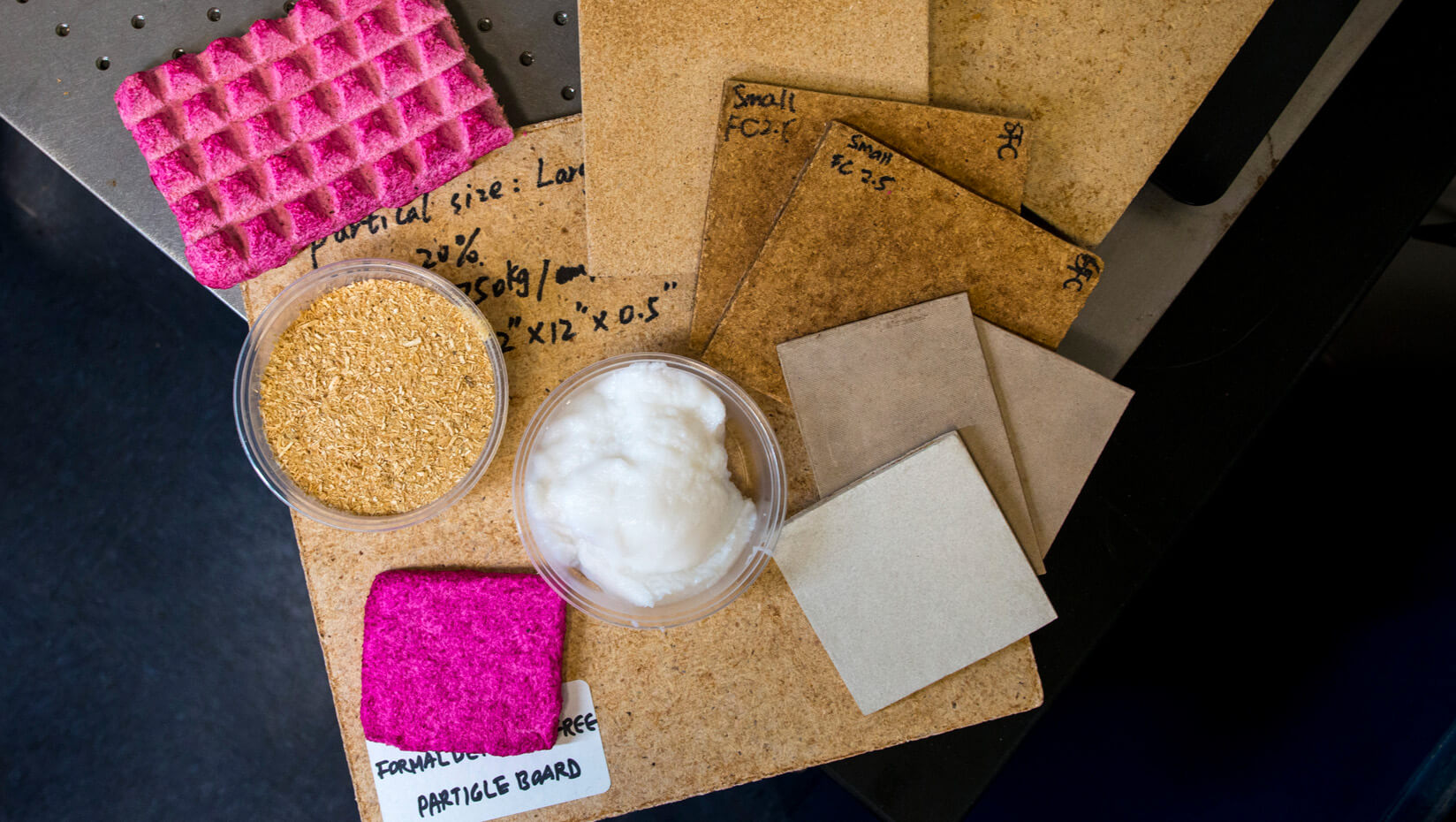

He’s advancing three — one of which is a scratch-, fire- and water-resistant flooring system made of CNF and cement.

Tajvidi is collaborating with the Washington state-based company C3 (Ceramic Cement Corporation) to produce the eco-friendly, durable flooring product.

C3, which produces high-end, fast-curing cement that sticks to wood, is contributing in-kind materials and expertise to the endeavor.

Tajvidi also is developing and testing an alternative to traditional drywall made of plaster, other materials and additives. His version, which is made with CNF and wood particles, is lighter and a better insulator. Tajvidi plans to make the core fire resistant, as well.

And thirdly, he’s partnering with G-O Logic to create a lightweight interior wall covering system that’s easy to mold into various shapes. G-O Logic is a Belfast, Maine firm that makes advanced building products for the high-performance construction market.

FiberLean Technologies, a global producer of FiberLean products that combine CNF and minerals, has contributed $10,000 cash and $10,000 in-kind support toward implementation of the wall-covering product.

UMaine researchers Douglas Gardner, Douglas Bousfield and Jinwu Wang are co-principal investigators on the project. While developing the new products, the team intends to use fire-resistance technology previously tested with support from the University of Maine System Research Reinvestment Fund (RRF).

In June, Tajvidi and several students from UMaine’s Laboratory of Renewable Nanomaterials will take samples and panels of products to the TAPPI Nano 2018 International Conference on Nanotechnology for Renewable Materials in Madison, Wisconsin.

Three years ago, Tajvidi led a UMaine team that was awarded a $350,000 grant by P3Nano to use CNF as an eco-friendly binder for strong particleboard panels. Urea-formaldehyde currently is used as binder and the U.S. Environmental Agency has classified formaldehyde as a probable human carcinogen.

Tajvidi says the UMaine team has made significant strides with the project, including learning how to remove water from particleboard panels without using heat.

Challenges remain, though. Some of the adhesion and dewatering mechanisms in the process are unknown. And while CNF products have considerable market promise, Tajvidi says techniques and methodology need to be optimized so mass production and commercialization of CNF products is economically feasible.

Product commercialization that leads to jobs and improved forest health is an exciting, worthwhile goal, says Tajvidi, who also is a cooperating faculty member with the Advanced Structures and Composites Center.

“Large-volume applications of cellulose nanomaterials such as these are unthinkable without having access to the unparalleled research facilities at the UMaine Composites Center, where most of the scale-up effort will take place,” he says.

Maine mills could be modified to handle production, says Tajvidi, who adds that he has numerous other ideas of how to utilize the magic of CNF in a variety of other products.

Contact: Beth Staples, 207.581.3777