Optimizing a novel CNF Vacuum Coating Process with Machine Learning – USM and UMaine research collaboration

Amir Kordijazi, PhD, is one of three USM faculty members conducting research through partnerships with UMaine researchers. He shared with us a summary of his research:

Estimates indicate that human exposure to microplastics, through both air and commonly consumed foods, varies from 203 to 332 particles per person per day [1]. Previous studies have highlighted sub-lethal effects, including inflammatory, immune, and metabolic disorders, in organisms such as algae, zooplankton, fish, and mice, as a consequence of exposure to microplastics. This serves as an early warning, signaling potential health risks for humans associated with the ingestion of plastic particles, as they have the capacity to harm human systems and disrupt normal metabolic processes [2].

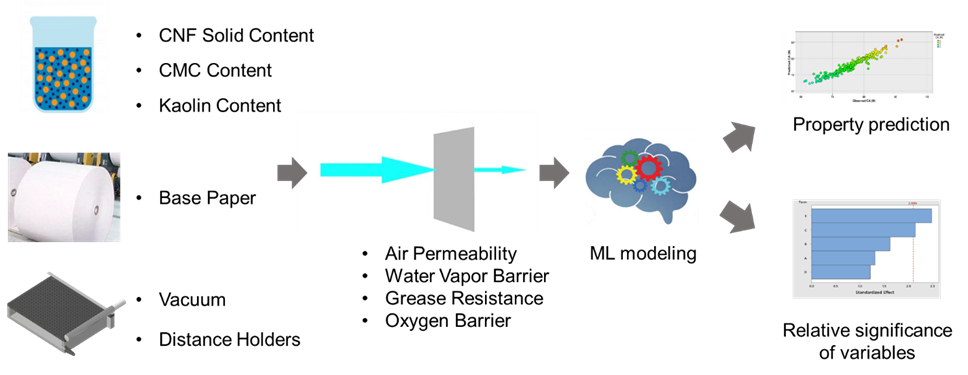

The goal of this project is to design textured paper surfaces for use as single-use medical waste, replacing plastic. Specifically, it aims to create a novel coating system using cellulose nanofibril paper as an alternative to plastic. By optimizing the coating process, the goal is to achieve suitable O2 permeability, water vapor permeability, and air permeability. Preliminary research has identified various coating process variables that influence the final properties, including paper basis weight, CMC content, kaolin content, post-processing time, and oven drying conditions. Given the potentially vast design space, the project aims to develop machine learning algorithms to aid in the search for optimal processing conditions that result in a high-performance coating. Experimental and simulation data will be utilized to train the machine learning algorithm. Once trained, the developed models will assist in understanding the underlying physical and chemical principles governing the coating’s properties and identifying optimal conditions for processing coatings with desirable properties.

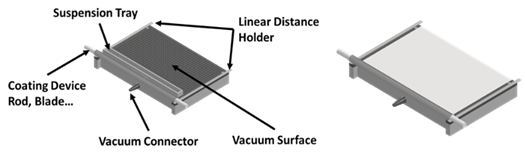

Vacuum coating method

Research framework

As part of our inaugural cohort for the BRAIN (Biomedical Research and AI Nexus) initiative, two undergraduate computer science students—Bradan Craig, a junior, and John Quinn, a freshman—are contributing to the software development of the project. Their work includes generating training data and building advanced machine learning models to explore the relationship between processing parameters and the resulting properties of the coated surfaces. Additionally, PhD student Sandro Zier and junior undergraduate Zech Hoeft are focusing on hardware development, aiming to construct a lab-scale system for the coating process. This system will be scaled up to pilot and eventually industrial levels.

References:

1. Cox KD, Covernton GA, Davies HL, et al (2019) Human Consumption of Microplastics. Environ Sci Technol 53:7068–7074. https://doi.org/10.1021/acs.est.9b01517

2. Jadhav EB, Sankhla MS, Bhat RA, Bhagat DS (2021) Microplastics from food packaging: An overview of human consumption, health threats, and alternative solutions. Environmental Nanotechnology, Monitoring & Management 16:100608. https://doi.org/10.1016/j.enmm.2021.100608