Processing Resources

CORE partners with facilities at the University of Maine that provide access to equipment and services related to prototyping, device fabrication, and media production. See below for more information on the Microfabrication Cleanroom Facility and the Innovative Media, Research and Commercialization (IMRC) Center.

Microfabrication Cleanroom Facility

Cleanroom at a glance

The CORE Microfabrication Cleanroom is a 3500 ft2 class 1000 cleanroom that maintains dedicated instrumentation for micro- and nano-fabrication of microsensor technologies, and for atomic-scale materials synthesis research.

CORE staff work closely with the Frontier Institute for Research in Sensor Technologies (FIRST) research center to support research, learning, and development.

Cleanroom Technical Services

- Microlithography: Mask Aligners, Photoresist Spinners, Vapor Primer, Photoresist Asher, Laser Lithography and Machining

- Thin Film Deposition: Electron Beam Evaporators, RF and Pulsed DC Sputter Deposition Systems, Plasma-Enhanced Chemical Vapor Deposition, Paralyne Coater, Atomic Layer Deposition

- Characterization: Surface Profilometer, Spectroscopic Ellipsometer;

- Dry Etch: Deep Reactive Ion Etching (DRIE), Reactive Ion Etching (RIE)

- Wet Etch: Spin/Rinse/Dry, RCA Clean, KOH Etch, Solvent Benches

- Thermal Processing: Four Stack Diffusion Furnaces, Rapid Thermal Annealing, Controlled Atmosphere Furnaces

View transcript of this video.

Cleanroom contact

- Henry Carfagno, Research Facilities Operational Specialist

Phone: 207.581.3382, Email: henry.carfagno@maine.edu

Cleanroom service rates

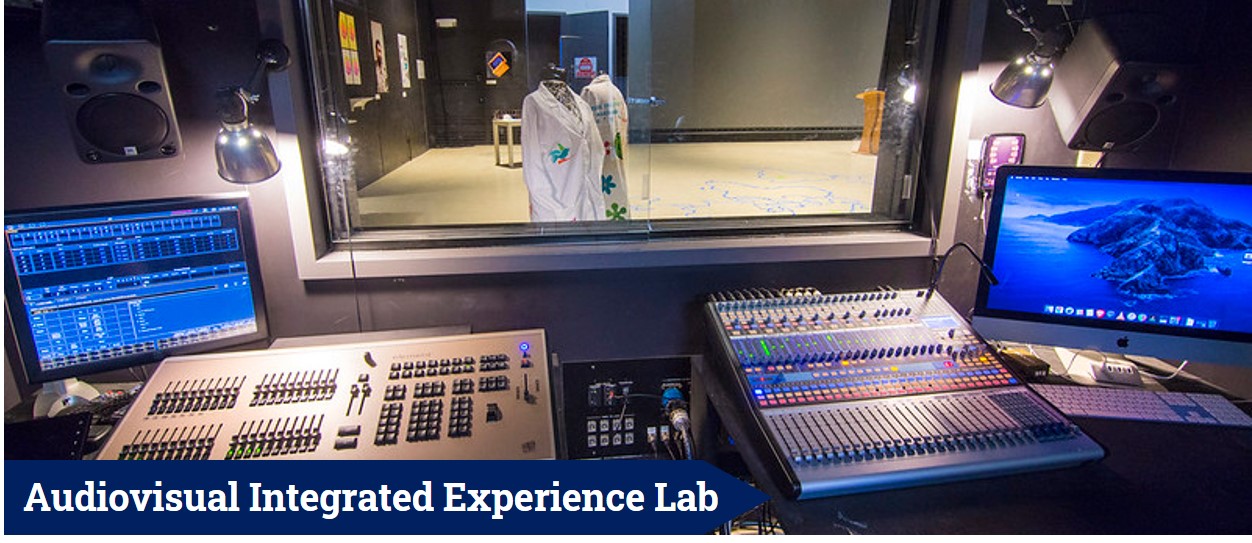

Innovative Media, Research and Commercialization Center (IMRC Center)

IMRC Center at a glance

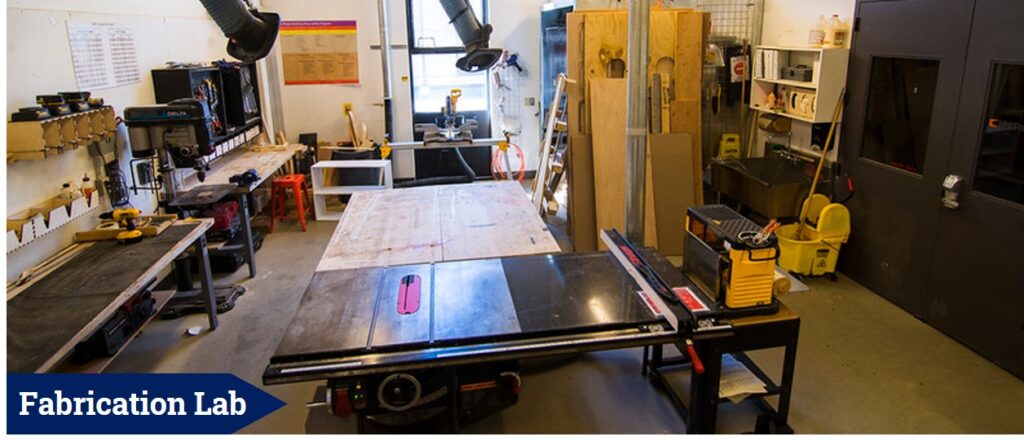

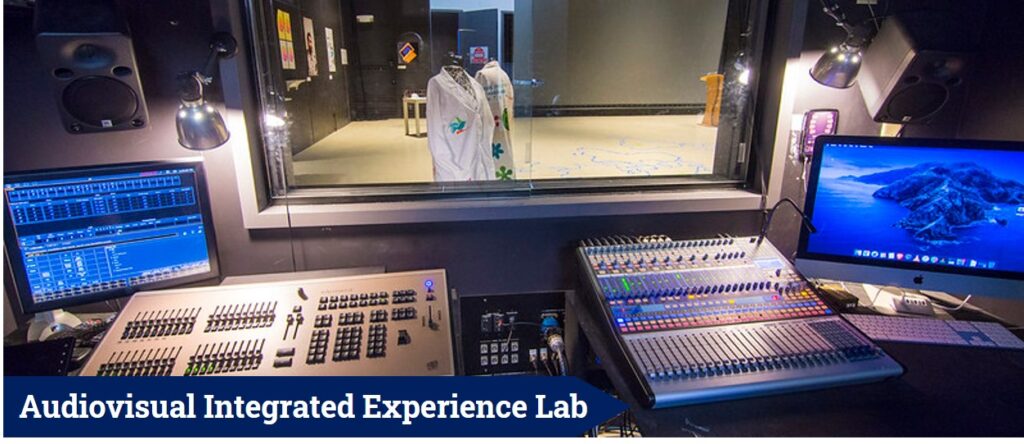

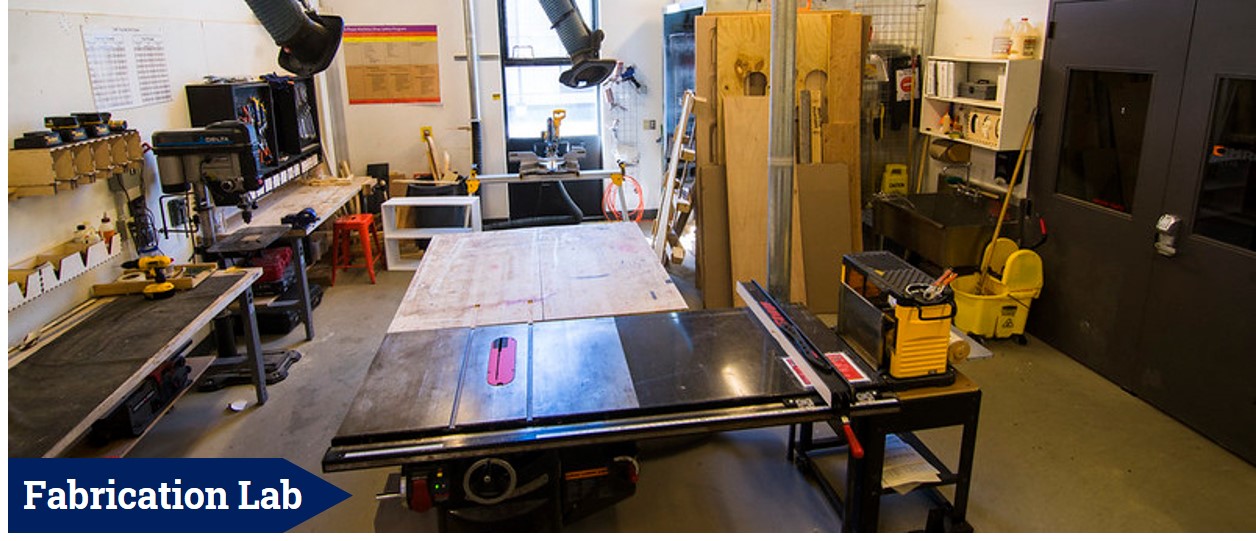

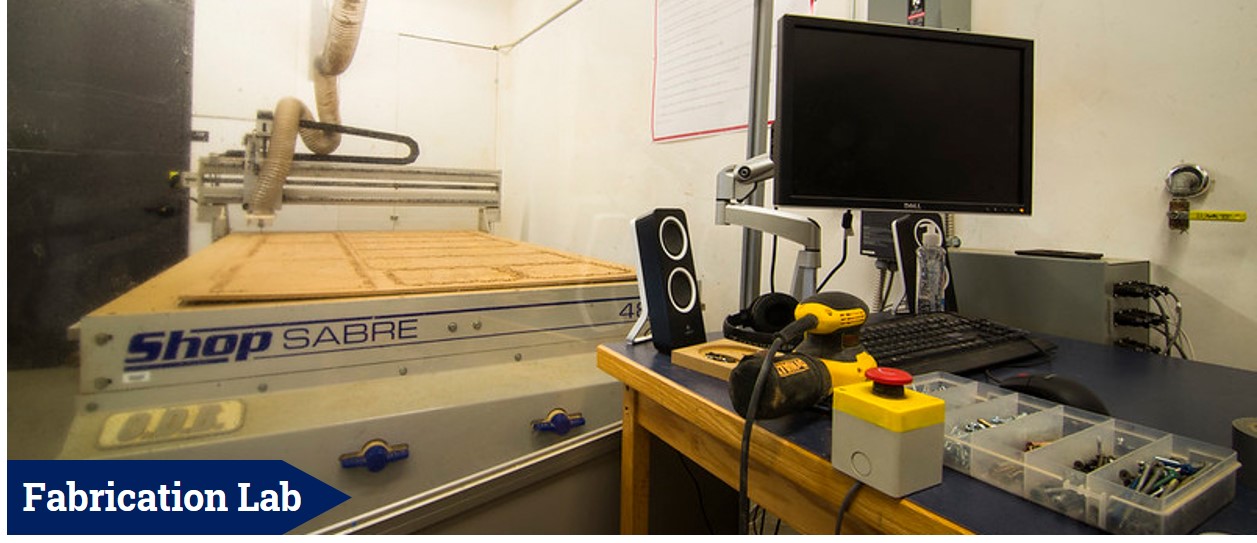

The IMRC Center provides access to high-performance research, design, media production, and prototyping tools and state of the art workspaces, as well as in-house technical support and training for members of the University of Maine and the surrounding region.

IMRC Center Technical Services

- Computer numerical control (CNC) milling

- Laser cutting/etching/marking

- Extrusion and stereolithographic 3D printing

- Large format 2D printing

- Vinyl printing/cutting/transfer

- Audio recording and post-production

- Video editing and post-production

- One-on-one instruction

- Product prototyping

- Events, presentations, exhibitions, trade shows, workshops

IMRC Center Contacts

- IMRC Center General Assistance

Phone: 207.581.8822, Email: imrc@maine.edu - Drew Hooke, Operations Manager

Phone: 207.581.3327, Email: drew.hooke@maine.edu