Milk jugs to military pallets: student engineers work toward a sustainable future

Three undergraduate students studying mechanical engineering at the University of Maine are working with recyclable plastic and wood material to create a sustainable resource for the U.S. Army. In collaboration with 3D printing company re:3D Inc. in Austin, Texas, the UMaine Advanced Structures and Composites Center is identifying viable mixtures of wood, paper or cardboard waste and plastic waste to 3D print shipping pallets.

Shipping pallets made of wood are burned or buried after losing structural integrity, practices that are not only bad for the environment, but potentially dangerous for military personnel. Using recycled plastic and wood waste is a two-step approach to waste mitigation: pallets would be created from plastic found at military waste dumps, such as milk jugs, water bottles and portable toilets, and they could be broken down onsite and reused.

“I think sustainable engineering is where the future of the industry is — finding ways to make our current practices more sustainable,” said Micah Morton, a UMaine junior from South Texas and ASCC intern. “And that’s what I hope to do.”

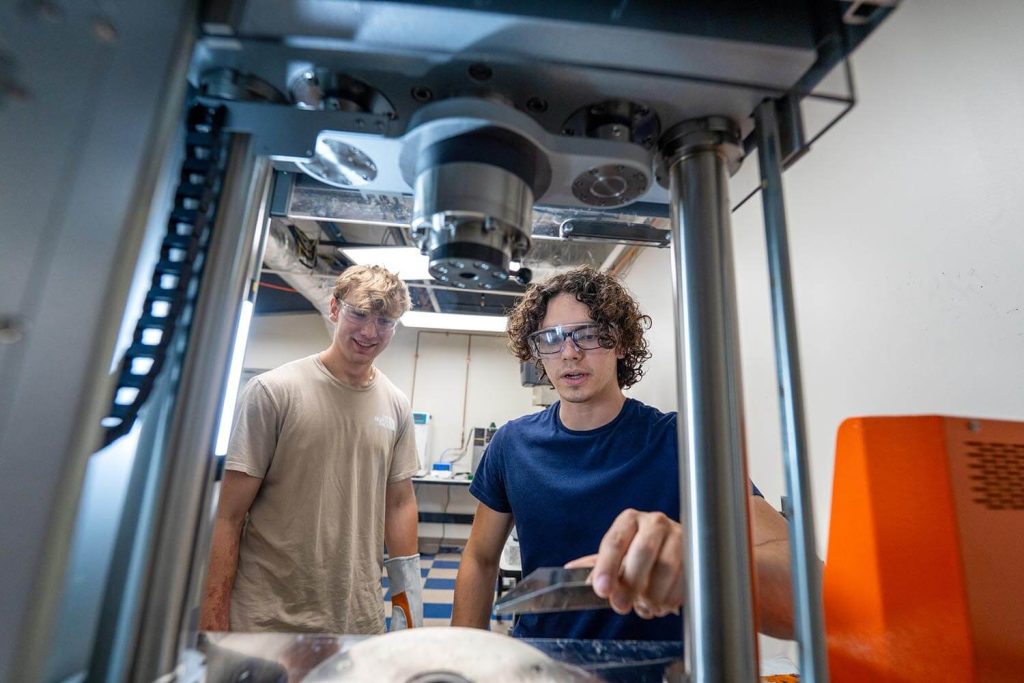

Before the three UMaine interns started their tests, re:3D identified typical plastics disposed of at military depots or installations and determined which mixtures would be the best to test. It’s been the students’ job to identify the most compatible ratios of those mixtures by running tests, such as for strength, tension and elasticity. Morton said one of the logistical challenges has been creating names for each new mixture and ratio they test, since many have the same compounds.

The students are also training to use industry-applicable software and practicing how to work together as a team. During the summer, they huddled around the same machines 40 hours per week. Throughout the semester, they’ll document their work with tables, charts and graphs and prepare to publish.

Patrick Ferrell, a senior engineer at re:3D, said when hiring recent graduates, they like to see projects a student has stayed committed to from start to finish. While 3D printed creative decor and trinkets are interesting, Ferrell said students who have completed research in a university or industry setting show an extra level of investment.

“I really love to see people that are so passionate about this work that they’re willing to spend those extra hours and evenings to take on the research projects and sit by the pieces of equipment and tend to the apparatus to make sure it’s working and get robust, reliable and important results,” said Ferrell, who is also leading the pallet project.

He added that the ASCC has several of re:3D’s printers on site and has established a good relationship with their company and reputation for materials development, specifically for bio materials and composites. “When we were looking for a partner,” he said, “it was an obvious choice to seek them out.”

In a competitive field like engineering, internships are invaluable resources to help students get jobs after they graduate. Some aim for two by the end of their senior year. Morton said he applied to over a dozen for the summer between his sophomore and junior years. He heard back from just two or three and took the one at the ASCC. It has a reputation among engineering students as a place to gain field experience and secure internships.

“It’s something I feel like every single engineering student knows about and is privy to, and then they want to go there because of all the cool projects,” said Sawyer Richard, a senior from Cape Elizabeth and ASCC intern. “It’s a great experience, and it’s great on the resume — great across the board.”

Siamak Shams Es-Haghi, a polymer engineer and assistant research professor of rheology and polymer science at the ASCC, recruited the three students from a class he taught, trained them and designed their experiments. He has also been supervising them throughout their internship and is the research lead for the project.

Jack Bernardo, the third intern and a junior from Rhode Island, said every step of their experimental process required a different machine they had to learn how to use. Morton said that they also had to familiarize themselves with different software for data analysis and graphing.

“It allows you to understand how a lot of different things work, because nine out of 10 things that we buy have some level, some amount of plastic in them,” Bernardo said. “If we can make those better, I don’t see a reason not to.”

All three interns see their work intricately tied to the environment and hope to forge more sustainable practices as mechanical engineers.

Samantha Snabes, co-founder of re:3D, said interns bring energy and enthusiasm to the workplace that reminds her how cool her job is. Snabes added that re:3D has hired several undergraduate and graduate interns and helped others secure jobs with industry partners.

“I’d say the number one thing that I want to do with my career, one way or another, is either make life better for the future or for us now,” Richard said. “That’s the mantra of engineering in general, is to make life better and safer for everyone around us.”

Contact: Ashley Yates; ashley.depew@maine.edu and MJ Gautrau; mj.gautrau@maine.edu