Wujcik developing wearable sensors that stretch and repair themselves

Sensors that can be worn or attached to clothing play critical roles in health care, robotics and entertainment, among other fields. The sensors help doctors and nurses monitor patients’ heart rate and pulse; inform prosthetic and robotic devices when they hit an object or surface; and create motion-capture in movies and video games. Conventional attachable sensors, however, are typically made with rigid and brittle semiconductors like silicon and are uncomfortable.

Evan K. Wujcik, University of Maine assistant professor of chemical engineering, is trying to make the technology more comfortable and easier to fix by developing wearable sensor systems that stretch and repair themselves like skin. These systems, which will take the form of sleeves, shirts or suits, could also be easy to recycle.

“I think stretchable electronics are the electronics of the future,” said Wujcik, who holds a joint appointment with UMaine’s Advanced Structures and Composites Center. “They’re less likely to break, they have a longer lifetime, they produce less waste and they impact many, many aspects of the world.”

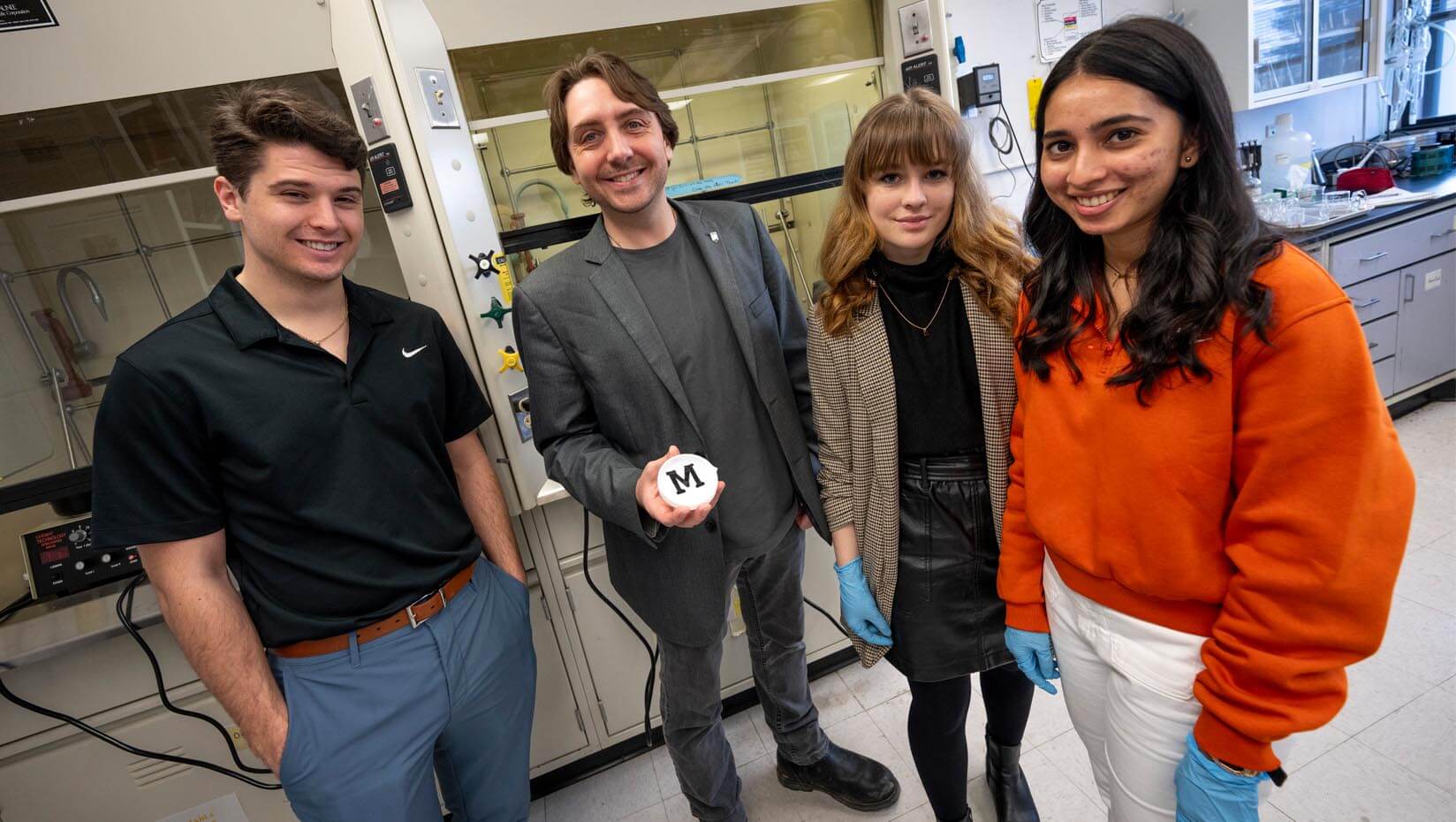

To support Wujcik’s work, the National Science Foundation (NSF) awarded him a $523,438 CAREER award, the organization’s most prestigious for early career faculty. Chemical engineering Ph.D. students Colton Duprey and Arya Ajeev, as well as 4+1 Master of Science in biomedical engineering student Sara Maslaczynska-Salome are working with Wujcik on the project, along with several undergraduates.

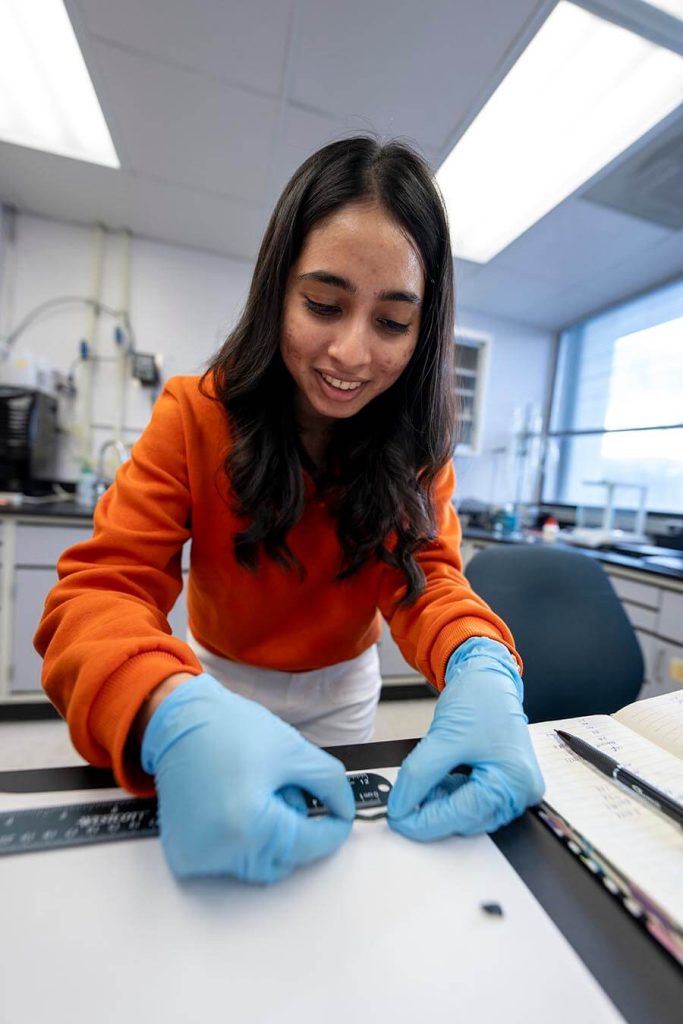

Wujcik and his students developed a prototype wearable sensor system in the form of a thin film made of polymers and dopants — small molecules that enhance the electric nature of the polymers. The properties of the polymers and dopants allow the system to bend, twist and stretch up to 30 times its original size.

Wujcik and his students developed a prototype wearable sensor system in the form of a thin film made of polymers and dopants — small molecules that enhance the electric nature of the polymers. The properties of the polymers and dopants allow the system to bend, twist and stretch up to 30 times its original size.

When torn in half, the film pieces reattach themselves within three hours. Attraction inherent between the molecules forces the pieces of material back in contact with one another over time. Wujcik said if the fragments are pinched together, they merge instantly.

“If you can fix these and allow them to do it on their own, it can reduce waste, which will be better for the environment,” said Wujcik. “Our material is also recastable. You can recycle the old material and use it for new sensors.”

The NSF CAREER award allows Wujcik and his students to further study the synthesis, structure, electrical and self-healing properties of wearable sensor systems. These materials consist of the conductive polymer polyaniline, acidic polyacrylamides and dopant molecules.

Through additional research and experimentation, Wujcik said he hopes to devise better methods for tailoring the properties of these wearable sensor systems, such as increasing or reducing their stretchability and conductivity.

“I hope to develop some kind of formula for what we need to get desired results,” he said. “We’re trying to better understand these systems, because we have a lot of complex moving parts and not many systems can self heal and stretch the way ours does.”

Wujcik also hopes to create YouTube videos about basic and advanced polymer sciences and the roles they play in everyday life; activities K–12 teachers can give to their students; and an interactive tabletop exhibit about polymers for the Maine Discovery Museum in Bangor.

Additionally, he is currently offering a polymer science course, with modules about stretchable and conductive polymers for a number of applications, for UMaine seniors and graduate students.

“We can bring students into the lab to play with the materials, get hands-on learning experiences, to better understand how they work,” he said.

Contact: Marcus Wolf, 207.581.3721; marcus.wolf@maine.edu