UMaine IMRC uses its tools to preserve historic fly rods — including Teddy Roosevelt’s

Fly fishing is an essential piece of Maine’s history and culture. The artists at the University of Maine’s Innovative Media Research and Commercialization (IMRC) Center knew this when they were approached with the task of using the tools at their disposal to help Thomas Rod Co., a historic fly rod maker based in Brewer, preserve and recreate its legacy designs — including the one personally used by President Theodore Roosevelt over 100 years ago.

Steve Campbell, the owner of Thomas Rod Co., has always liked the old version of things, like vintage cars and wooden canoes. When Campbell bought the company, which has been making traditional bamboo fly rods (as opposed to their modern graphite, fiberglass and composite counterparts) for over 100 years, he knew he wanted to bring back some of the traditional models that had made the company legendary.

“I’ve been fly fishing since I was about 10 years old. I found out about these old bamboo fishing rods and started reading about them, and it turned out I couldn’t afford them, so I started trying to learn how to make them so I could make them myself,” Campbell laughs.

The dilemma, though, was that Campbell didn’t have access to all the materials that he needed to bring these designs back to life. In order to make the Thomas-style fly rods, Campbell has to prepare six strips of bamboo, which are eventually bundled into a hexagonal rod, using a milling machine that shapes pieces with a narrowed tip, known as the rod’s “taper.” Fly rod tapers look the same to the untrained eye, but they are ever-so-slightly different, often at the scale of thousandths of an inch. Those discrepancies make a huge difference for the dynamics of the rod.

“You have dry fly rods that are meant to cast flies over the surface, streamer rods which are meant to go under the water,” Campbell explains. “It’s a different action to get the fly moving if it’s under water as opposed to being right on the surface, so the rods have a different taper to them.”

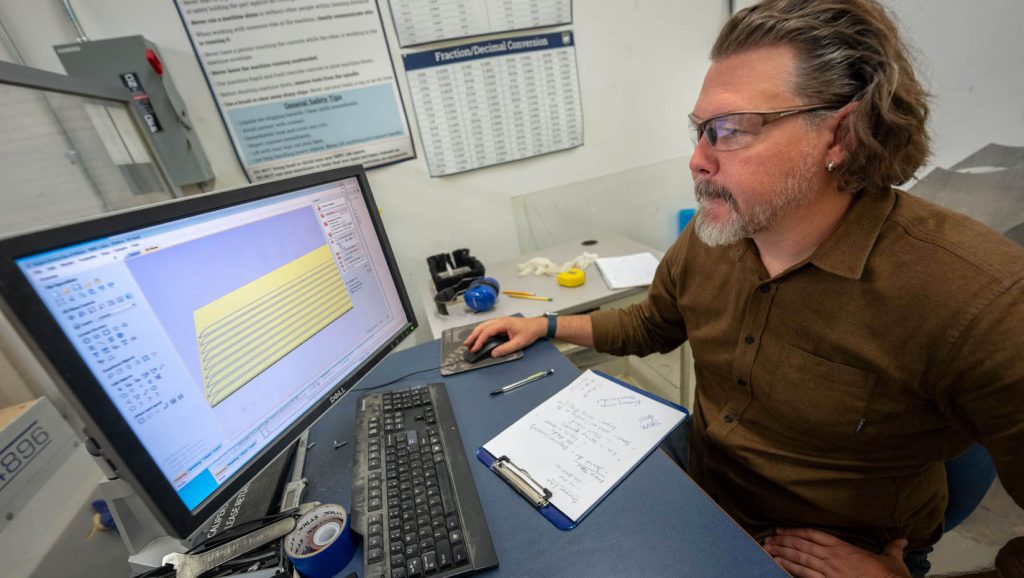

The machine that cuts the bamboo into these tapers uses templates made of a strong plastic called delrin. Campbell had the specs for the three tapers he was missing — an eight-and-a-half-foot dry fly rod, eight-and-a-half-foot wet fly rod and a nine-foot dry fly rod — but he didn’t have the templates that he needed to make the rods a reality. Based on past experience, he knew that a CNC, or computer numerical control, machine would be a good fit to get the precision that he needed.

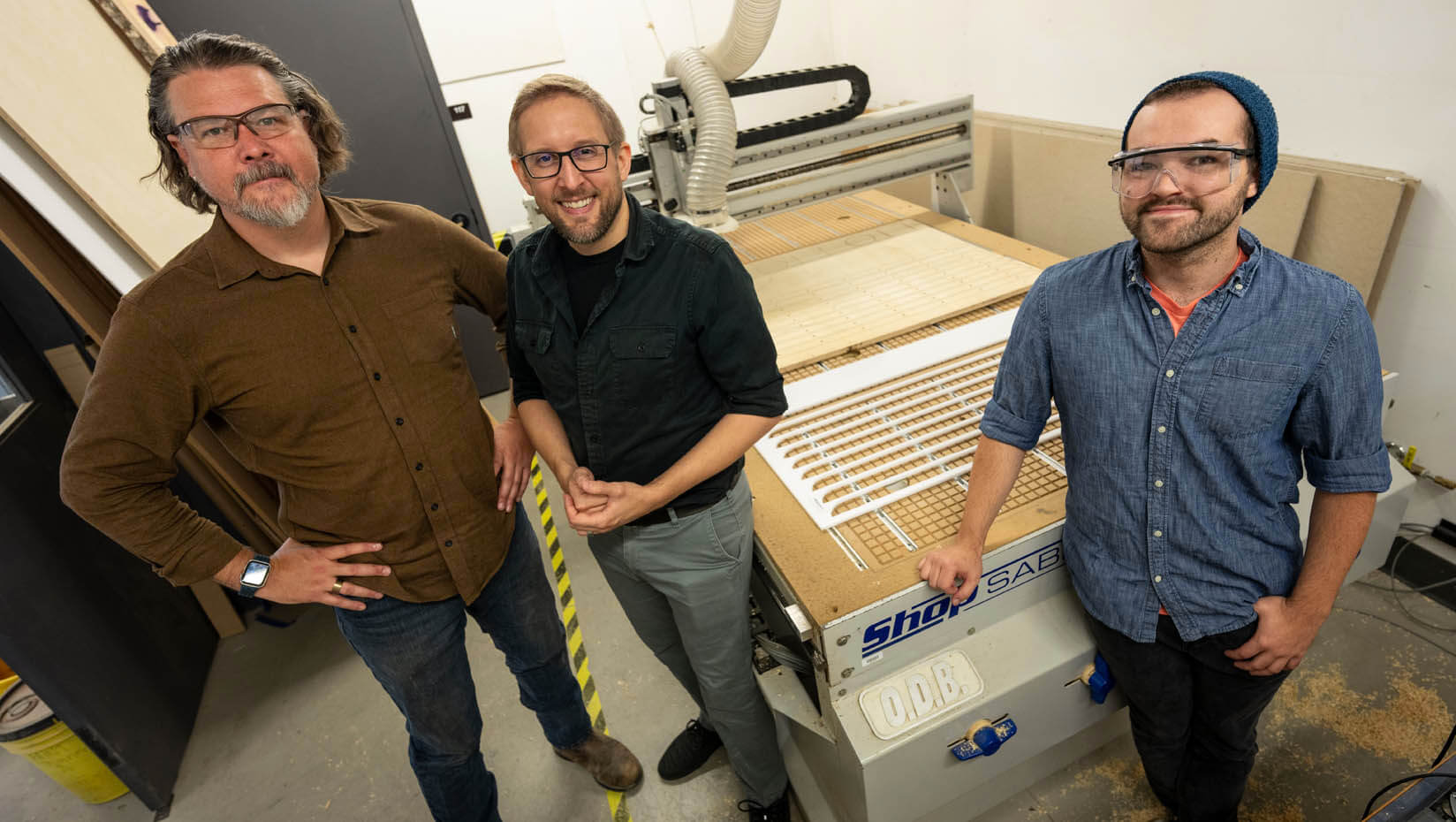

Campbell first reached out to the Advanced Manufacturing Center, and was eventually put in touch with Drew Hooke, operations manager, and Sean Michael Taylor, research engineer at the IMRC Center, which is a part of UMaine’s Coordination Operation Research Entities (CORE). The IMRC Center was equipped with a CNC machine that could accomplish what Campbell needed. The center was a better fit for the boutique task at hand — and the project appealed to their multidisciplinary sensibilities.

“We do like the fact that it’s still tied to part of history and antiquity — that makes it even better for us,” Taylor says. “We love studying technology, especially ancient ones. That’s still where we get a lot of our ideas. There’s something we can learn from this, and that’s the part of creativity I love studying.”

Once the IMRC Center ironed out the details with Campbell, the fly rod maker sent over the existing files that he had related to the tapers. Taylor refashioned the files to work with the CNC machine, and he and graduate student laboratory technician James LeBlanc practiced cutting the tapers out of wood. Once they had perfected the process, they cut the final tapers out of delrin.

Once the IMRC Center ironed out the details with Campbell, the fly rod maker sent over the existing files that he had related to the tapers. Taylor refashioned the files to work with the CNC machine, and he and graduate student laboratory technician James LeBlanc practiced cutting the tapers out of wood. Once they had perfected the process, they cut the final tapers out of delrin.

“The CNC is a powerful and accurate machine that enables us to create precise, measured cuts necessary for a project such as this. It is always exciting to collaborate with companies that are so ingrained in classic Maine pastimes,” LeBlanc says.

Taylor says that one of the great things about this project is now the files will exist and preserve these historical designs for generations to come.

“As long as you keep a good history of the files you have you don’t have to go and reinvent the wheels,” Taylor says. “It’s a fantastic opportunity to support a local business that has been here for many years.”

The tapers made at the IMRC Center have also helped Campbell with one of his highest profile projects yet. A client recently came to Campbell with the original Thomas fly rod used by President Teddy Roosevelt dating back to 1913, looking to make a pair of replicas for him and his son. That rod is an eight-and-a-half-foot wet fly rod — one of the tapers that Campbell had been missing until he was put in touch with the IMRC Center.

“It’s great because now I have those templates for those tapers the customers ask about. I was worried I wasn’t going to be able to until I found [the IMRC Center]. I was pretty happy to have them be able to do it,” Campbell says.

Contact: Sam Schipani, samantha.schipani@maine.edu