Center offering additive metal manufacturing services, training to Maine businesses

Transcript

John Belding:

The Center for Additive Manufacturing of Metals is an MTI grant that we received in collaboration with 35 Maine companies, where we’re working with those Maine companies to realize the technology of additive 3D metal printing. So taking metal particles, 3D printing them and turning them into solid metal objects.

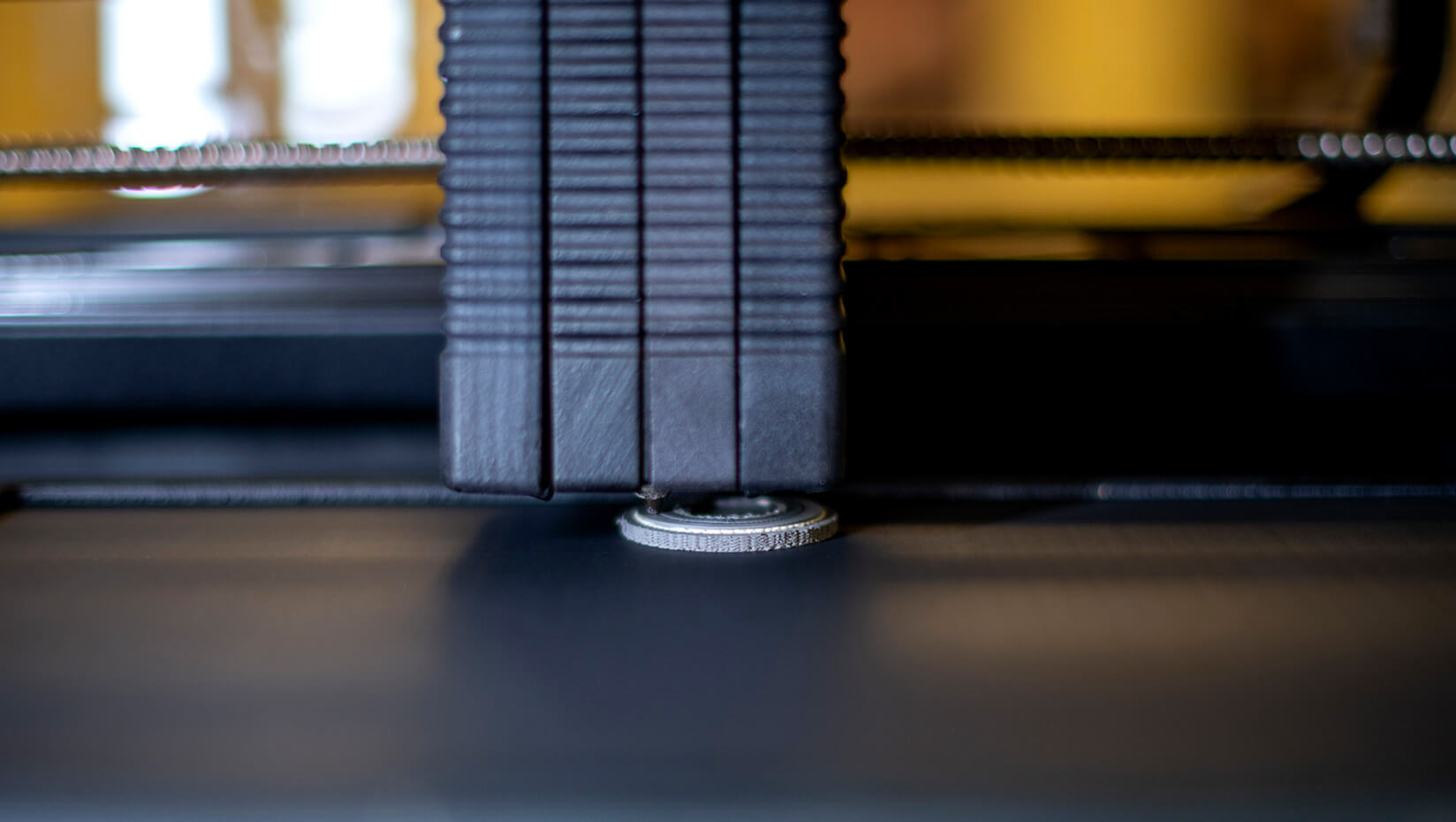

We have three different machines here. The first machine is a 3D printer. It uses a metal powder that’s bound into a wax. That wax is put into the head and it almost like a hot glue gun, squeegeed out onto the build platform.

Once the build is complete, we take out the sheet. It then goes into a debinding process which basically removes all of the wax and leaves just a plasticized binder.

Then it goes into a sintering furnace which shrinks it — the material — by 20 percent and consolidates the part into a 98.9 percent hard part; final consistency.

What we want to do is work with the companies, do the research, take the risk away from them so they can come to us and say, “This is what we want to build.” So we can work with them on the training, we can work with them on the design, the research aspect of making the parts. Once they turn around and get a good product and realize the potential of it, then they may say, “Hey, we want to have one of these machines in our facility,” and they’ll go buy that down the road.