Team 2: 3D Printed Stirling Engine

Project Summary

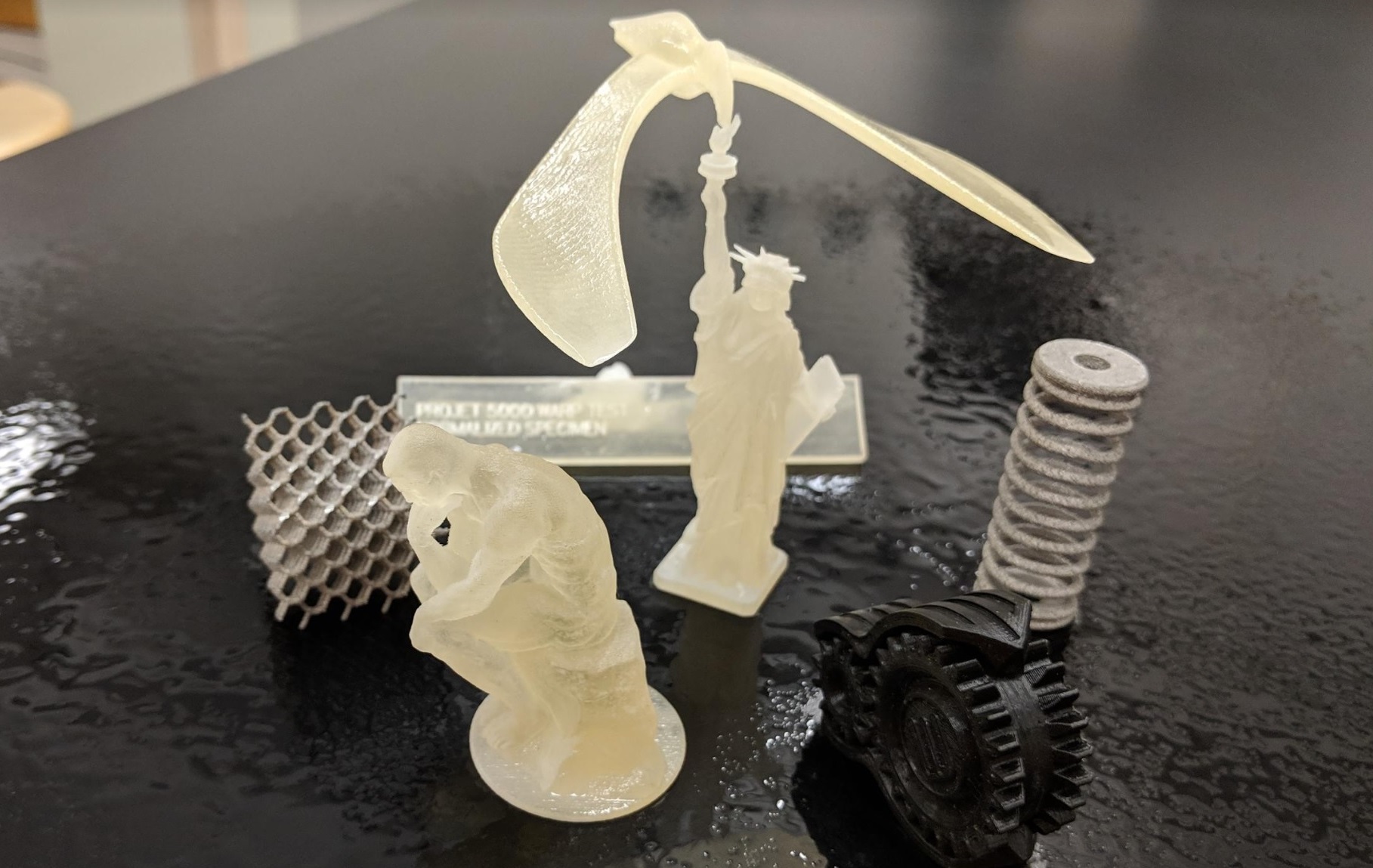

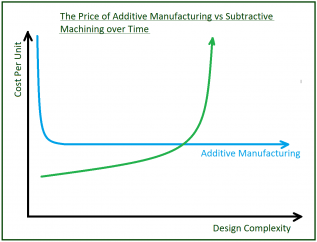

Additive manufacturing of metals (AMM) is a relatively new process currently with an unknown value in today’s fabrication shop. As additive technology continues to develop, recent advances in AMM have caused interest among manufactures across the state. The Advanced Manufacturing Center at the University of Maine is one of many Maine manufactures interested in learning more about this technology. Our team has been tasked with manufacturing an operational Stirling engine to demonstrate the capability and practicality of AMM when compared to conventional subtractive manufacturing (SM). A Bound Metal Deposition (BMD) Desktop Metals Studio printer will be utilized to manufacture the majority of the engine. The engine will consist mostly of printed parts using the new printer, but one of the shafts that need to be very precise will be bought. Hardware will also be bought for assembly due to the low cost and easy access to hardware. This, along with welding and post-process-machining, will continue to demonstrate the wide range of uses of AM in fabrication, as well as the ability for our team to stay within our budget.

If you are looking to learn more about our groups project or how to make a tax deductible donation you can contact our team’s preferred point of contact, Kyle Rooney, at kyle.rooney@maine.edu.

Project Scope

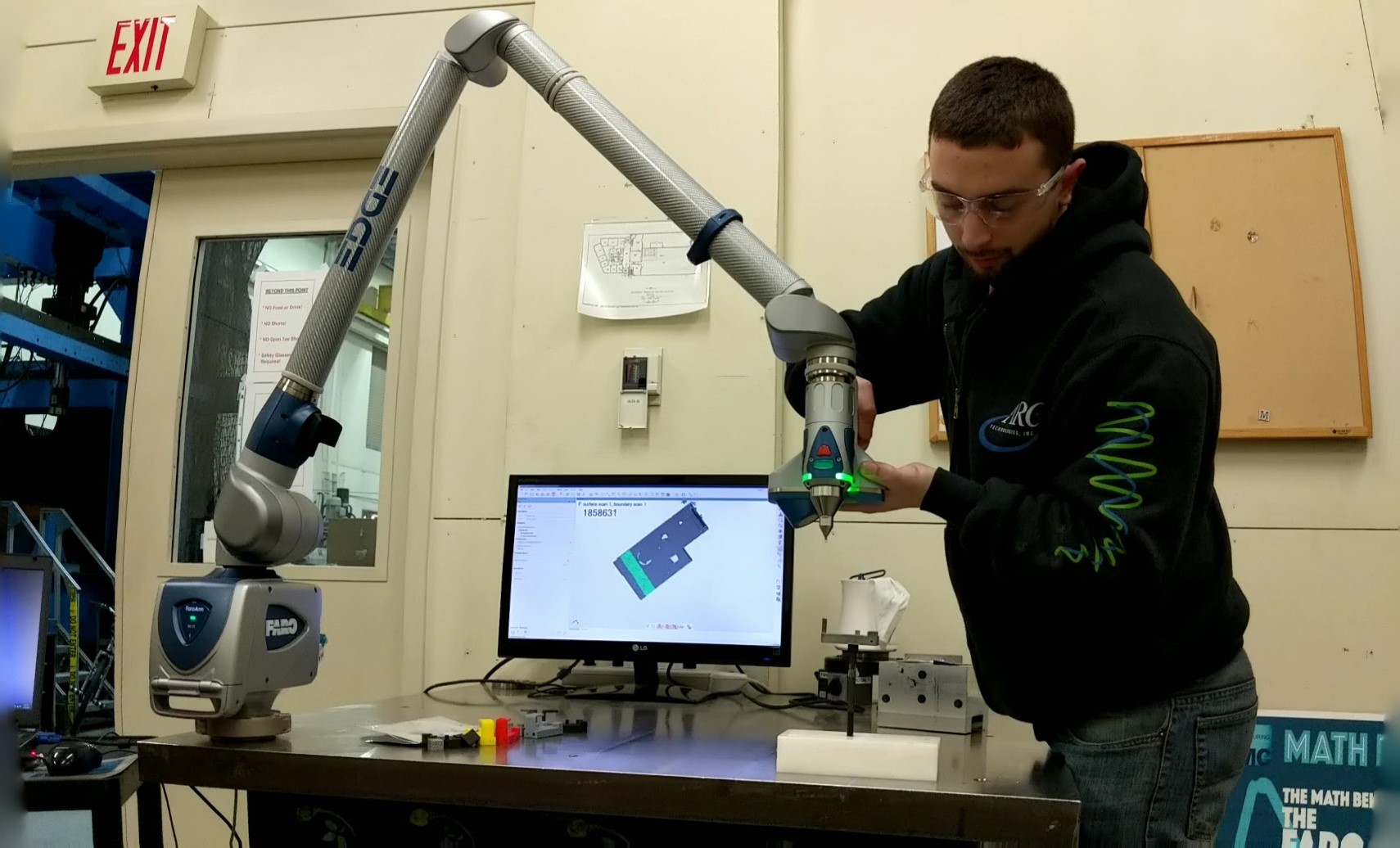

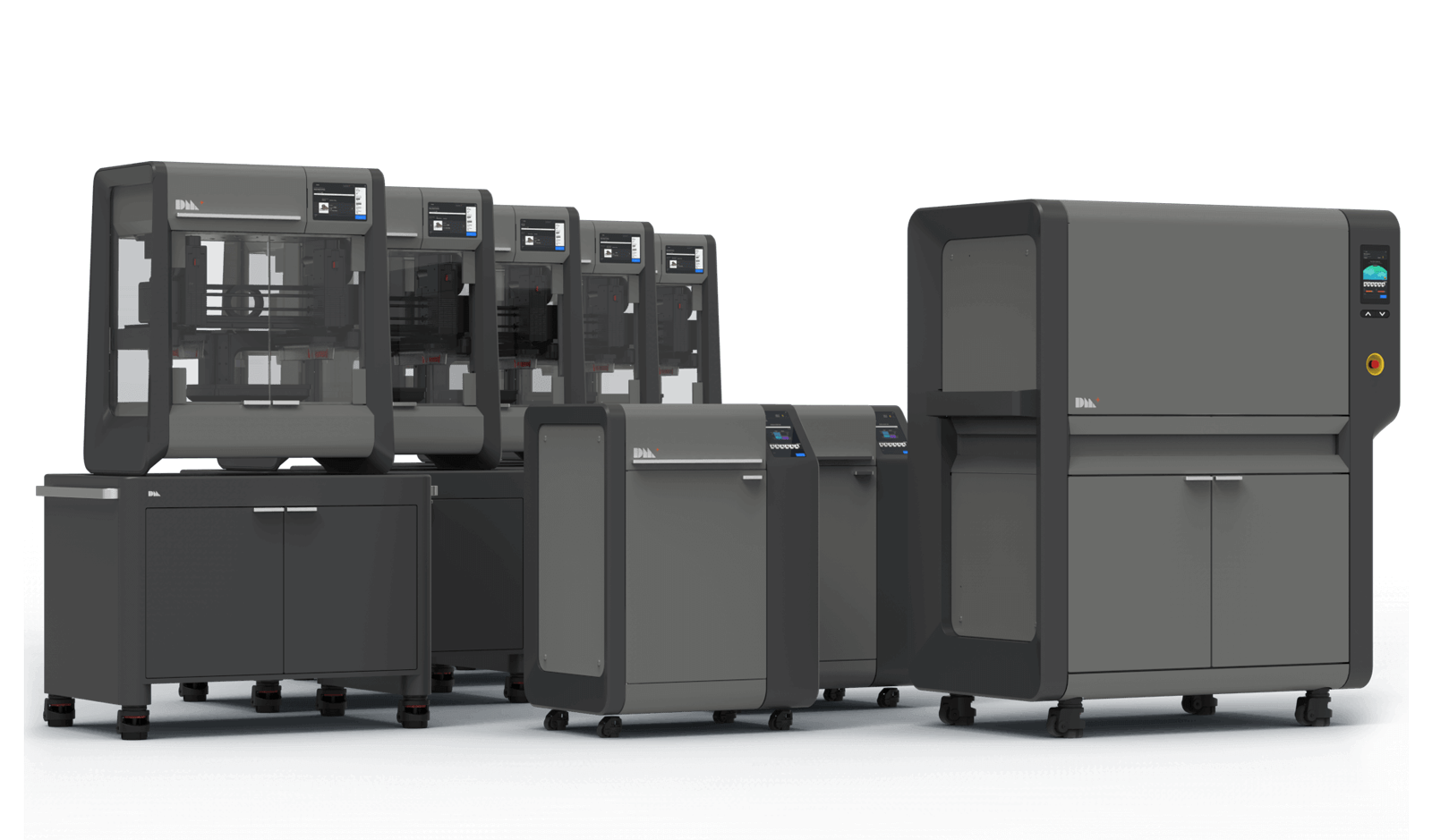

The Center for Additive Manufacturing of Metals (CAMM), housed at the University of Maine’s Advanced Manufacturing Center (AMC), recently purchased a Desktop Metals Studio . The Desktop Metals Studio printer uses Bound Metal Deposition to sequentially extrude layers of a metal-binder composite in a layer-by-layer fashion to construct 3D metal artifacts. CAMM has proposed that the printer be used to “strengthen Maine’s precision manufacturing technology sector through industry driven support, applied research, workforce development, and dissemination of information involving Additive Manufacturing of Metals (AMM).” Success of this proposal will use enhanced part functionality, reduced lead times, and eventually reduced costs to bring economic growth to Maine’s manufacturers.

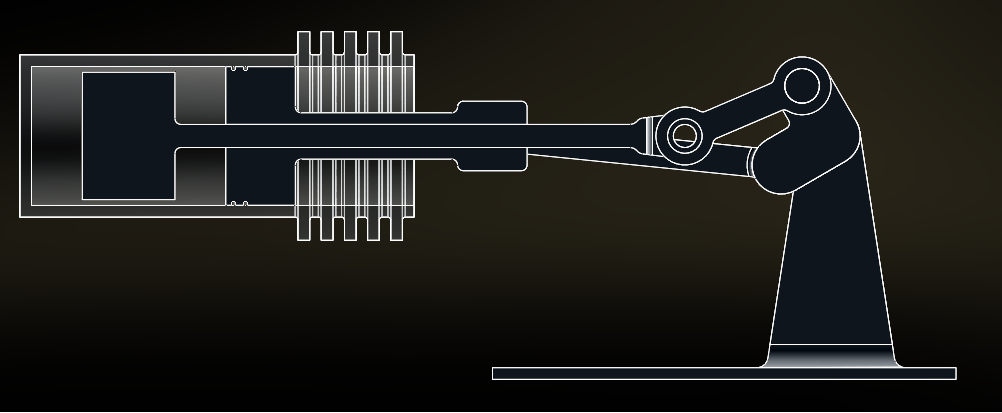

A Beta Stirling engine was chosen as a test platform for the Desktop Metals printer due manufacturing complexity of these engines. AMM’s anticipated challenges include but are not limited to:

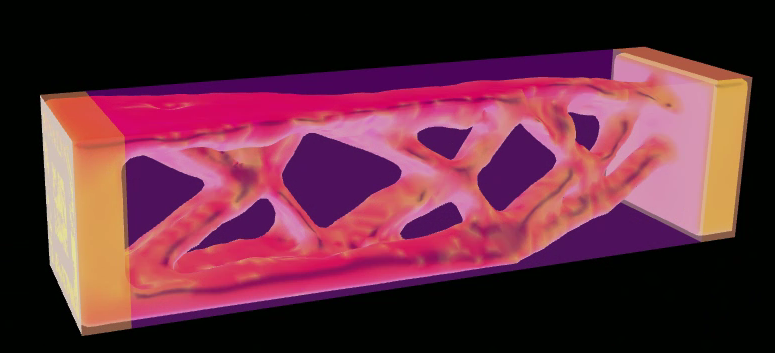

- Minimization of build time and mass via topology optimization while retaining both rigidity and strength.

- To maximizing surface area in order to optimize heat transfer between the heat source and engine as well as between the engine and the working fluid.

- Determining post process requirements feasibility.

- Provide physical properties of the printed medium such as tensile strength, fatigue, coefficient of thermal expansion, porosity, and permeability in order to compare these results to the expected values.

- Measure the precision, accuracy, and repeatability of the printer.

- Investigate the microstructure of the manufactured build to analyse any anisotropic material properties.

- Compute an analytical model for both the thermodynamic processes and the mechanical properties such as combined loads (e.g., hoop and axial stress), abrasion at wear surfaces and anisotropic thermal expansion

Acknowledgements

The team would like to give a special thanks to:

Keith Berube

For his help in locating test methods for various properties.

David Dvorak

For his help in the thermodynamics of the engine.

Aaron Grant

For his knowledge and experience in 3D manufacturing.

Alex Murchison

For his help in setting up our website

The Team

Quinn Campbell

Quinn is from Saco, ME. He got his start with 3D printing and engineering during his junior year of high school where he took part in a vocational drafting class. This lead to two summer internships where he worked primarily with CAD and design. During Quinn’s junior year of college he worked part time during the school year as an undergraduate research assistant at the Advanced Structures and Composites Center, where he helped with research and the application of FDM 3D printing. Currently, Quinn is the president of the 3D Printing Club here at the University. His preferred method of contact is through email at Quinn.Campbell@maine.edu.

Michael Filiault

Mike is a 4th year Mechanical Engineering Technology student from Hampton, NH. He has been involved with mechanical engineering most of his childhood with a keen interest in cars and motorcycles. Following graduation, Mike will be working at Woehner LLC as a junior design engineer. Mike can be reached through email at michael.filiault@maine.edu.

Kyle Rooney

Kyle is from Amesbury, MA. He is a senior in the MET program here at the University and is expected to graduate in Fall of 2019, along with a minor in Mathematics. He is currently employed as an undergraduate research assistant at the University researching combined heat and power systems. He has not yet set his mind on Graduate school or the work force upon graduation, but he’s open to a variety of opportunities. You can contact Kyle at Kyle.Rooney@maine.edu