Ergonomic Sitting Device

Kelly Burden, an experienced registered nurse and physical therapist assistant from Maine, and her colleagues have asked the MET department to take their prototype of an ergonomic sitting device to its next phase. The project will encompass updating the current prototype, analyzing possible design solutions, and manufacturing 20 new units.

Team Members

From the left to right, Ben Rosenbaum, Nasser Alqahtani, Connor Clarey, Michael Desgrosseilliers

1- Ben Rosenbaum

Ben Rosenbaum grew up in Topsfield, Massachusetts where he spent most of his time playing sports, hanging out with friends and playing guitar. He originally chose Construction management Technology at the University of Maine, but transferee into the MET department. After graduation, he hopes to find work in the New England area.

2- Nasser Al Qahtani

Nasser is a senior in Mechanical Engineering Technology at the University of Maine. He is from alhasa, Saudi Arabia. He graduated from high school in 2013 then he came to US in 2014 to complete his degree. He likes to play Soccer and watch it too. He is looking to graduate in May 2019 then go back home to find a good job as an engineer.

3- Connor Clarey

Connor Clarey is a University of Maine Student and a major in Mechanical Engineering Technology. He is here to help in the groups progress in completing the Ergonomic Sitting Device. A little about him self is he is a huge film fanatic, he enjoys analyzing the structure of the cinematography and the camera shots throughout a show and movies. He also enjoys the thought process and build into a project of his own, whether it is building miniature scale roller coasters or even a seating mechanism that helps with posture and health.

4- Michael Desgrosseilliers

Michael Desgrosseilliers is originally from Northern Virginia. He was seeking a new experience which brought him to the University of Maine. He is a fourth year Mechanical Engineering Technology Major working on the Ergonomic Sitting Device capstone project. He spent this past summer working for a mechanical contracting company specializing in HVAC design. His interests in the engineering field are primarily in green energy and energy reduction.

Weekly Updates

04-29-2019 To 05-05-2019

The team finally has completed all the section required for the senior project capstone. Last Wednesday ” Maine Day”, the team has successfully presented the hole project front of the MET’s professors, the client, and the other students. Also at the same day we handed in our final prototype to the client. Finally, the team has finished the final report and we are ready to submit it.

04-22-2019

This week the group has received the final order of springs for a final attempt at the perfect size for spring functionality. The cushions for the top plates have been ordered and will arrive by the following week in time for the presentations. The team has also been working on completing the final capstone presentation for the upcoming Maine day.

04-15-2019

This past week the group has continued to perfect the recent spring functionality concept for the final design. The first prototype with an incorporated spring function was brought to the lab in Boardman 118 for a load cell compression test. The test consisted of gathering data for four differently located points on the prototype. Data acquisition was collected for each trial. Finally, the team is awaiting for the final bottom plates to finish printing at the 3D printing club.

04-08-2019

This past week we have finished all machining operations as well as top plate 3D printing operations. We will be completing the 3D printing operations for all bottom plates over the next week. Springs have been ordered to test out one final and possible component as an addition to the final assembly. If this component does not fail, extra milling operations will be completed in the upcoming week to complete the final product. The team also met up with our client to discuss all progress to date, as well as the possibility of the new spring addition.

04-01-2019

The team has been working at the night lab sessions in the machine shop on campus to produce all aluminum parts in the final product. More plates have also been printed at the 3D printing club. The team will meet wit the client this upcoming week in order to go over current progress, as well as discuss the final addition to the overall design.

03-25-2019

We have used machine tool lab and 3D printing club to build our parts. Additionally, we have sent MK Services a drawing to fabricate it. MK Services is a machine shop located in Massachusetts and we expect a fixture donation from them. The fixture will be used for the load cell test.

03-18-2019

Spring break!!

03-11-2019

At this stage, we have completed manufacturing our prototype and it is ready for testing.

03-04-2019

The team is still working on assembly prototype for testing as well as IR#3, to be ready on 13th March.

02-25-2019

All our designs are ready. The next phase is to start manufacturing and testing them. And also we are ready to start working on IR#3

02-18-2019

We have already finished most of the design for a stamp forming manufacturing process, finished project demonstration presentations, and we are currently working to design a formed seat for the top plate. The stamp forming process will be used to make the prototypes of the final product and involved bending and bottoming of parts. Currently, we are designing a formed seat for the top plate. Among some of the most important factors that we are considering include the frictional properties of the top plate to ensure that we guaranteed maximum comfort to the user of the device.

02-11-2019

The team met with Jonathan Roy at the Composites center where we discussed going through a process of 3D printing and stamp-forming processes for the final prototype. The team worked on updated the prototype of solidworks to get it ready for a stamp-forming process. The team also has been working on prepping for the upcoming capstone presentations.

02-04-2019

we are in the final phase of finishing the new prototype for 3D printing, and we are preparing the final touches for the in class presentation.

01-28-2019

we are going back to the original prototype with modifications, and then we will have a 3D printed pro type for it in a week.

01-21-2019

During the winter break, the team revised IR#2 as well as completed the client contract and sent it to the client.

12-10-2018

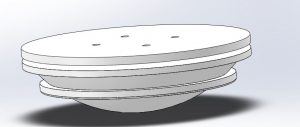

The team has completed the 3D printing process for the first concept model to test out functionality. The model has been fully assembled and is ready to be shown to the client. Ben will meet with the client in Portland within the next week. The team will set out to further the manufacturing process over the winter break and next semester.

12-3-2018

The team has sent the Solidworks part files to the 3D Printing Club for 3D printing of the seat plates. The team has also ordered and received the turntable and the bolts to connect all the parts together. Once the plates are finished printing, the team will be able to assemble the first prototype. The team is working hard on Interim Report 2 which will be completed before Wednesday. An order for PLA 3D printing material will be placed for the 3D printing club.

11-26-2018

The team has created a Solidworks assembly of the new concept design that has fewer parts and still meets functionality requirements. The concept is being discussed further with the client and her respective colleagues. Once given the go-ahead, the group will move into a 3D printed design. The group plans to get parts ordered for prototype and have Solidworks parts finished for 3D printing for next week.

11-19-2018

This week the group has designed a solidworks model of the final concept design. After construction, the group has decided to look into further concepts in order to simplify production by lowering the amount of overall components in the final design.

Sponsors

Kelly Burden

Madeline Johnson

Sharon Thomas

Mechanical Engineering Technology Department

Kelly Burden:

Over 20 years experience in the healthcare industry as a physical therapist assistant and registered nurse. Strong leadership and organization skill set developed during this time. Extensive experience and understanding of negative impact of maladaptive positions.

Sharon Thomas:

Over 25 years in direct healthcare to include home care, acute care and long term care. Experience with team building and leadership.

Madeleine Johnson:

15 years experience as an Occupational Therapist in mental health, geriatric and pediatric settings with a focus on sensory processing, education and wellness. Leadership in management for many of those years. First hand witness of after effects of extended maladaptive positions.

Point of Contact

Acknowledgments

Nasser Alqahtani – nasser.hassan.al@maine.edu

Michael Desgrosseilliers – mikedsixteen@maine.edu

Ben Rosenbaum – ben.rosenbaum@maine.edu

Connor Clarey – connor.clarey@maine.edu

Mechanical Engineering Technology- University of Maine

Michael King-Sr. R&D Applications Engineer-UFP Technologies, inc.

Gary Gagnon-Division Manager-G&G Products LLC

Jonathan Roy- Structural Thermoplastics Research Engineer

Supervisor

-

Brett Ellis, Ph.D., P.E.

Associate Professor, Mechanical Engineering Technology & Program Coordinator

207.581.2134 / Boardman Hall, room 215A