Team #4 Low-Cost Projector

Project Summary

In Sierra Leone there are a large number of children and families that do not have access to a steady education. It is difficult for teachers to reach students with the teaching materials that are accessible to them right now. Currently, the solution for reaching students, if they are able to be reached, is hiring a vehicle to transport the large projector and generator. Additionally, an operator must be hired in order to setup, maintain and operate the system. A number of problems including the the affordability, generator requirements, durability, and maintainability have been identified with this solution.

The team has been tasked by the Servant Heart Research Collaborative to design and produce an effective projector solution. The solution designed by the team must be able to be seen at distances up to 75 feet in a classroom with no window coverings, while also being able to run for up to 6 continuous hours without being plugged in. Additionally, the projector and the power supply must weigh less than 20 pounds and be able to fit comfortable in a backpack.

Meet the Team

Jack Rivet is a senior pursuing a B.S. in Mechanical Engineering Technology at the University of Maine. He is expected to graduate in the spring of 2021. He currently works for CMI concrete professionals in Old Town, Maine doing flatwork. Jack is from Groton, MA. Following graduation he is hoping to find employment in the pharmaceutical industry in the New England area. Outside of school, Jack enjoys outdoor activities such as golfing and snowboarding, he also enjoys watching hockey and baseball.

Cameron Trafford is a senior Mechanical Engineering Technology student from Limington, Maine. He is currently an intern at CellBlock Fire Containment Systems managing inventory and factory upgrades. Cameron is expected to attend graduate school for a masters in Business Administration. In his free time Cameron enjoys working on his truck and motorcycle, along with skiing and hunting.

Austin Sheehan is a senior Mechanical Engineering Technology student from Old Town, Maine. He currently works at JSI Store Fixtures designing and building refrigerated grocery store fixtures. After graduation he is looking to find employment locally within Maine. Outside of school, Austin enjoys hunting and fishing, as well as playing hockey.

Nicholas Boutin is a fourth-year Mechanical Engineering Technology Student from Old Town, Maine expecting to graduate in the spring of 2021. Over the 2020 summer he interned the ND Paper Mill in Old Town, Maine as an engineering intern. After graduation he is looking to find a job in the state of Maine.

Weekly Updates

- 14 September – 14 November – The team has been doing research regarding different available projectors, testing projectors and rooms on campus, exploring power consumption, and the use of battery packs. Additionally the team has been researching how different levels of light affect the visibility of projections.

- 14 November – The group met with the clients this past week discussing the progress we have made this semester so far and the direction the group is going in. Also the group worked on the IR 1 revisions that were due on Friday the 13. We received the $60 projector that we ordered to test the light levels we would need for the projector the group will be designing.

- 30 November – A Prototype design and manufacture of a modified iPhone and tablet projector have been completed. The two variations of the modified shoe-box projector were tested alongside the DBPower projector that was received a couple weeks ago. The light drop from the lens to the projection surface was recorded, along with the brightness level in the room, and the brightness of the projection on different colored surfaces.

- Tablet Shoe-Box Projector (Top View)

- iPhone Shoe-box Projector (Top View)

- iPhone Shoe-box Projector (Side View)

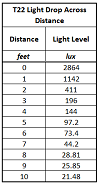

- 7 December – This past week the team has been working on testing the shoe-box projectors and the T22 DBPower Projector. It is very important to develop a model for the amount of light lost per foot away from the projector in order to ensure that the image projected is bright enough in Sierra Leone. Additionally, determining the amount of power required for a specific lumen output will be vital to ensuring that the battery or power supply system will power the projector for the required 6 hours per day.

Top to bottom: T22 DBPower Projector, iPhone Shoe-box Projector, and iPad Tablet Projector.

Table 1: Measured Lux at given distance from projector bulb.

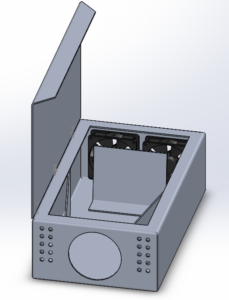

- 9 December 2020 – Solidworks model and drawings made for potential solution to phone projector. The casing will be made of aluminum, and there will be dual fans placed in the back to increase airflow through the case. The team has worked diligently in order to generate the Interim Report 2 that outlines all of the experimental work, research, and designing that has been done throughout the semester. It is the goal hopefully continue making design tweaks and improvements throughout some of winter break!

Solidworks model of solution for the phone projector.

- 16 December 2020 – The team met with the clients for the last time this semester in order to communicate the progress made throughout the semester, where we are at currently, and to introduce the next steps of the project. The clients were very pleased that we are continuing to work on two solutions, the newly designed phone projector for use in small groups, and the commercially ruggedized projector system for use in larger groups of students and may run for up to 6 consecutive hours without an outlet!

- 27 January 2021 – During winter break the team continued to work the design and fabrication of the phone projector system. Additionally, the team enjoyed some much needed time off.

- 28 January 2021 – The team began the semester by sending a purchase order for a set of computer fans for the phone projector design seen above. The fans are required to limit overheating of the phone in the extreme classroom temperatures. The team additionally ordered an H88 projector to compare with the T22. This will allow the group to proceed with the most ideal solution for the client.

- The team has been working diligently the last few days in order to complete the revisions to Interim Report 2 that was completed at the end of last semester, to update the team contract, and to draft a client contract displaying the description of the project, the deliverables that must be completed during the project, and the client requirements that have been asked of us throughout the project.

- 17 February 2021 – The team ha received a new projector (the H88). The team will be working over the next few weeks to test the H88 in order to make sure it will be suitable for use in classrooms in Sierra Leone. One of the concerns is that the projector only has a brightness of 1000 lumens. The H88 is (5.25″x3.75″x2.5″), weighs about 0.63 lbs, and consumes about 12 watts of power.

H88 Projector

- 22 February 2021 – The projector must be able to run for up to 6 consecutive hours without being connected to the power grid. The team has received a Hiluckey solar Power Bank. The power bank is rated for 25000mAh. The Hiluckey is (6.2″x1.4″x3.5″), weighs about 1.3 lbs, and provided about 14 hours of runtime for the H88 Projector.

- 25 February 2021 – The team will be continuing with the H88 projector and the Hiluckey solar power bank. In order to ensure that the projector system will not get damaged during transportation, a series of shock testing was done. A device with similar dimensions and weight was created and then dropped from a series of different heights onto different thicknesses of foam while recording data with an accelerometer. An iPhone 8 was used for data acquisition. The test setup is shown below.

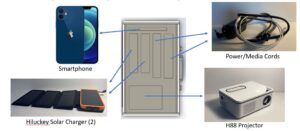

- 7 March 2021 – At the conclusion of the shock testing, a casing was designed. The case has space for the H88 Projector, 3 Hiluckey Solar Power Banks, a smartphone, and all of the needed cords to run the projector system.

Exploded View of the designed case for the projector system

- 11 March 2021 – Before constructing the case, the team needed to test how long the Hiluckey battery pack could power the projector without needing to be charged. The Hiluckey battery pack powered the H88 for a total of 14 hours but began to have some performance issues after about 8 hours. The team concluded that the final design for the case would only need to have room for 2 Hiluckey chargers, the H88 Projector, a smartphone, and the proper wiring. As can be seen below there is a slot for a smartphone at the top, the two left middle slots are for the Hiluckey chargers. The 2 right middle slots are providing space for the necessary wiring and remote for the H88 projector. The slot at the bottom is to provide space for the H88 Projector.

Drawing of the Final Case Design

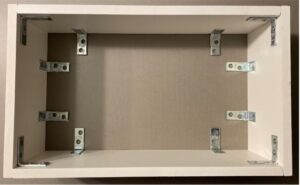

- 17 March 2021 – With the final design for the case determined, all of the necessary parts were ordered and have been received by the team. The next step taken was to begin constructing the outer shell of the case with PVC board purchased. The beginning of the build can be seen below.

Illustration showing the outer shell of the case

- 18 March 2021 – Once the sides of the outer shell of the case were constructed the top and the lid were then fastened onto the case. There was a gasket placed around the top of the case and caulking was put on all of the connecting corners in order to limit the amount of moisture that penetrates the case.

The Completed case for the Projector and all components

- 24 March 2021 – After the case was manufactured the team then began to work on testing how effective the case worked to protect the projector and all of the components inside the case. An initial drop test was designed and executed to determine how effective the shock testing device would work. The data was recorded with the maximum G-Force on impact being recorded and then the maximum velocity calculated. The simulation of the projector as shown in the experimentation diagram above, was dropped from a height of 12 inches onto different thicknesses of foam. The data was fit with a quadratic curve of best fit that had a coefficient of determination of 99.61%. It was concluded that the previously decided 1 inch layer of protection for the projector would be sufficient.

The plotted maximum recorded velocity

- 3 April 2021 – Once the initial drop testing was concluded the team then began to drop test the case with the projector in it to determine if the case would be proficient. The team weighted the case similar to how heavy it would be when fully loaded as it would be during transportation as can be seen below in the first image. The case was dropped from a maximum height of 6 feet and the damage sustained to the case can be seen in the first picture. The case only sustained a rounded corner and one of the latches was slightly open when dropped from a height of 6 feet twice. The H88 projector still functioned as it did before and did not sustain damage.

Case ready to be drop tested with H88

Damage to case after being dropped at a height of 6 feet twice

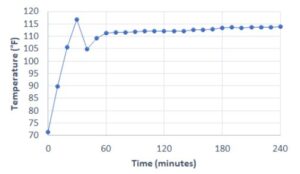

- 9 April 2021 – The team has been working to test the performance of the projector in high temperatures due to the projector needing to be able to function in temperatures reaching nearly 120 degrees Fahrenheit. The team created a chamber with a barrel and set the H88 projector on a 5 gallon bucket at the bottom of the chamber with a hair dryer oriented in the chamber to supply additional heat. There was also a type K thermocouple dangled down into the chamber connected to a multimeter to record the temperature inside throughout the test. The Chamber can be seen below. The projector was left on and the data recorded during the test can be seen below also.

Picture of the inside of the chamber

The recorded temperatures during the heat test

As can be seen in the graph above the temperature in the chamber reaches a maximum temperature of about 117 degrees Fahrenheit before reaching a steady state temperature of about 113 degrees Fahrenheit for about 3 hours. The projector did not lose any performance capabilities during or after the testing was completed.

- 17 April 2021 – Due to none of the classrooms in Sierra Leone being alike, it makes it difficult to determine how bright a classroom will be on a regular basis. This required the team to develop a light blocking solution to be used if the classroom is too bright for the projection to be seen clearly by the whole class. The team developed assumptions based off the pictures that were provided by the Servant Heart Research Collaborative and concluded that the best way for light to be blocked is by a solution that can be sourced in Sierra Leone. The team concluded that different sized black trash bags could be purchased in Sierra Leone and cut open to cover windows as can be seen below.

Light blocking solution covering the windows and allowing for the projection from the H88 to be easily seen.

- 22 April 2021 – With the end of the semester coming quickly, the team has worked to rebuild a case due to the damage sustained from the drop testing and has also began to start working on the presentation for Maine Day. The team is very excited to present all of the hard work done throughout this entire senior year and what we have designed for the children in Sierra Leone.

- 28 April 2021 – The team presented on Maine Day and the clients were very excited to see all of the work we have done. They cannot wait to test the system in Sierra Leone!

- 29 April 2021 – The Final case assembled with all of the components that would be contained in the case when it is being transported in Sierra Leone.

Fully loaded Case with all of the components

Picture illustrating all of the contained components.

The specified location for all components to be placed in the case.

- 3 May 2021 – The team has been working over the last few days to complete the final report that was due today, illustrating all of the hard work done over the year. The case with the projector, battery packs, and all needed hardware along with an instruction manual is to be turned over to the clients.

Team Advisor

- Professor Howorth

Email: peter.howorth@maine.edu

Point of Contact

Clients

Allen Morell, Servant Heart Research Collaborative

Email: allenmorell@comcast.net

Learn more about the Servant Heart Research Collaborative!

Video: Recent Sierra Leone trip by Honors College’s Servant Heart Research Collaborative