Team 9

Team 9 – Athletic Cart

Team Members

Casey Bogan

Sonja Robert

Mark Spaulding

Hunter Turner

Team Photo

Project Description

The athletic cart capstone team has been tasked with creating a more efficient, safe and affordable method of transporting and storing athletic trainers equipment. Various pieces of equipment include tape, ice, bandages and other necessary tools of the trade. The cart must also be a functional taping station so it will need to support upwards of 300 pounds, all while being light and maneuverable enough to transport in a SUV during away games.

Weekly Updates

5/4/2018

Maine day has come and gone and Team 9 have finished their capstone project! The team would like to thank everyone who took the time to come to our presentation and would like to give one final thank you to our sponsors and everyone who has helped along the way.

4/27/18

The plywood top has been cut to size and wrapped in foam and antimicrobial vinyl. Hinges have been attached to the frame and the cart will be finished in its entirety in the coming days. Finishing touches will be made leading up to the final presentation on Maine Day, May 2nd 2018.

4/20/18

This week the finishing touches have been put on the frame. ABS has been riveted and sealed with silicone to all the exposed sides of the frame. The casters have been attached and the doors are being fabricated and will be put on in the coming week.

4/13/18

This week, the team, with help from Joel Anderson, used the horizontal mill in the machine tool lab to remove excess material from the drawer channel to ensure a smooth fit. Also, the channel was welded to the frame by Mark at Allweld Fabrication and supplies in Old Town, Maine. Big thanks to Mark for fitting us into his schedule.

4/6/18

In the past week, the team was able to get the frame tacked into place. In the coming week, fellow MET student, Jake Davee, will be welding all the critical joints. Special thanks to Jake for his time and effort.

3/30/18

This morning Mark and Casey spent hours at the Mechanical Engineering lab in Crosby hall practicing tig welding with aluminum. By tacking the frame ourselves, the group will greatly reduce the cost of the frame welding which will help keep the current estimated budget below the allotted value. Special thanks go out to Stephen Abbadessa for accommodating us.

3/23/18

This week, the team has dedicated their time to getting the tubing cut to size. Dimensions were extracted from the solid model and pieces were cut on a horizontal band saw in the machine tool lab.

3/16/18

Spring Break

3/9/18

The team has agreed upon a fabrication timeline before departing for spring break and will begun constructing the frame in the coming weeks.

3/2/18

The team has picked up the 1″ x 1″ square aluminum tubing for the frame construction from Troy Industrial Solutions. In the coming week a specific timeline for fabrication will be agreed upon and begun.

2/23/18

This week the team received the donated decals from Banana Banners. Additionally, the cooler, drawers and fabric for the seat have been shipped.

2/16/18

The team has decided to get their frame materials from Troy Industrial solutions in Brewer, Maine and Banana Banners in Bowdoinham, Maine was kind enough to donate decals to add to the finished product. A very big thank you goes out to each company!

2/9/18

Team 9 has spent the last week formulating a complete parts inventory and budget. Prices for supplies are being compared and decisions on where to purchase materials will be made in the coming week.

1/28/18

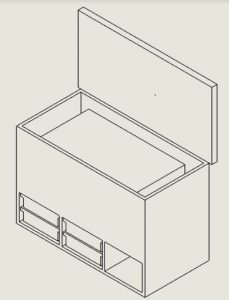

Team 9 has returned from winter break with a final concept selected. Pictured above is a general layout for how the final product will look (minus the casters). The upcoming week will be dedicated to exploring options for ordering the material (aluminum) necessary to build the frame. Considerations for welding the frame are also being ironed out.

12/1/17

Sample drawer and cooler have arrived. The drawer option looks to be a success whereas the cooler is a bit too large and will require a smaller version in the same concept.

11/24/17

Thanksgiving break, the supplies noted in the previous weeks update have veen ordered and will be arriving in the coming week.

11/17/17

Solid models of each concept are in the process of being created. The team has also be ordering a sample drawer and a cooler candidate for inspection and testing in the coming weeks.

11/10/17

The team has downselected the concept list to the 2 potential options seen below and are preparing a list of pros and cons for each to present to the client.

11/3/17

The storm on 10/30 has affected each of the athletic cart team members in unique ways. Given the circumstances the team has dedicated this week to conduct individual research when the opportunity becomes available. A final review of concepts will be conducted early in the coming week and sketches of the finalists will be included im next weeks update.

10/25/17

The athletic cart team has spent the past several weeks narrowing down the list of acceptable design concepts and will soon begin working with our client to select a final concept. As a group we have created a Gantt chart to keep a timeline of expected goals and are working hard to remain on track.

9/25/17

After several weeks of preliminary meetings and background research, the team has begun brainstorming what the concept should look like. In the coming week, each team member will formulate an individual concept to be discussed with the group.

Team Biographies

Sonja Robert is from Bowdoinham, ME and studying Mechanical Engineering Technology at the University of Maine-Orono, class of 2018. She has previously worked in the failure analysis lab at ON Semiconductor and is currently employed as a Teaching Assistant in the Machine Tool Lab on campus. Sonja is proud and active team member of the Athletic Cart capstone project..

Mark Spaulding is from Lincoln, ME and studying Mechanical Engineering Technology major at the University of Maine-Orono, class of 2018. He has previously worked as an intern at Foresight Engineering and is currently employed as a manufacturing engineering intern at JSI Store Fixtures in Bangor, ME. Mark is honored to be part of such a great team tasked with the Athletic Cart Project.

Casey Bogan is from Cornish, ME and studying Mechanical Engineering Technology at the University of Maine-Orono, class of 2018. He spends his summers and extended breaks working as a manufacturing engineering intern at Irwin Tool in Gorham, ME and during the school year he works as a mechanical engineering intern at Compotech Inc. in Brewer, ME. Casey is excited to be a part of the Athletic Cart capstone team and looks forward to the challenges ahead.

Hunter Turner is a third-year Mechanical Engineering Technology student at the University of Maine. Over the Summer, Hunter works at Smith & Wesson in Houlton, Maine as an intern, along with being a substitute teacher at the Easton Junior/Senior High School. Hunter hopes to continue his education by going to graduate school to obtain a Masters in Business.

Project Sponsors and Partners

Brianna Woodworth and Cristina Mountain

Banana Banners, Bowdoinham, Maine

Troy Industrial Solutions, Brewer, Maine

Acknowledgements

Brianna Woodworth, Cristina Mountain, Samantha Taylor, Jake Davee, Robin Riendeau & Karen Libby at Banana Banners, Joel Anderson, Scott Tomlinson, Professor Brett Ellis, Professor Keith Berube, Erin Ellis, JSI, Stephen Abbadessa

Point of Contact

Casey Bogan, casey.bogan@maine.edu