Forest Products

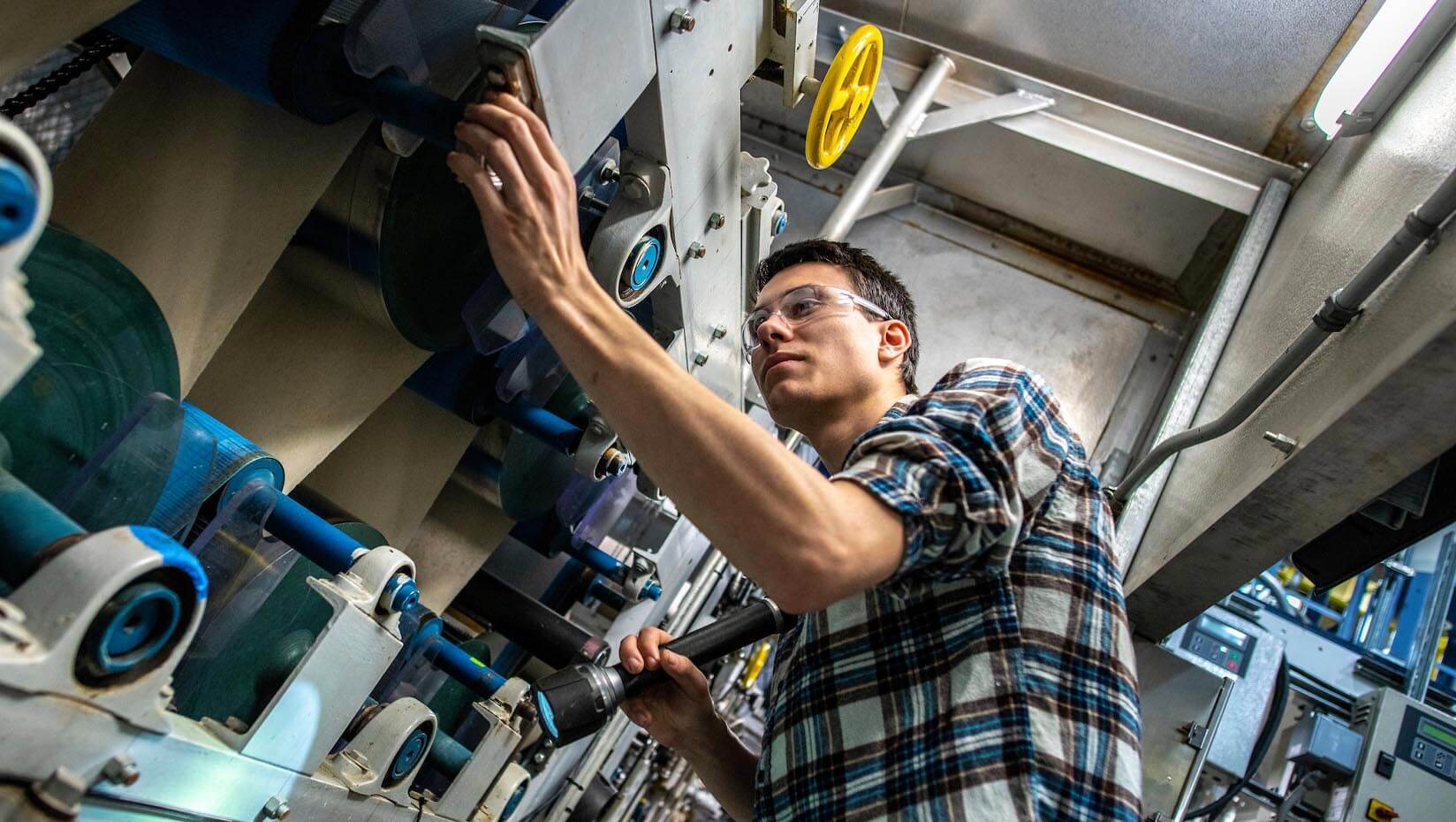

Pulp and Paper

For over 80 years, the University of Maine has offered a unique, open-access research experience where scientists, entrepreneurs and industry leaders work collaboratively to develop new pulp- and paper-based products and manufacturing processes. We provide science-based solutions and cutting-edge research expertise that allow our clients agile response to consumer preferences and trends. From benchtop analytical experimentation to production rate pilot trials, the University of Maine delivers full in-house processing, development and testing solutions.

Examples of our pulp and paper services include

- Complete chipping, digester, refiner and reactor operations

- Chemical and mechanical pulping capabilities from wood chips or recycle streams

- A full pilot-scale fourdrinier paper machine including flexible coating systems, precision drives, modern distributed controls, online scanning and calendaring equipment

- A variety of pilot and high-speeds coater systems and calendaring equipment

- Complete testing capabilities across all stages of the paper process, from raw materials and pulp characterization through fiber quality, chemical analysis and finished goods performance

- Patented cellulosic nanofibril manufacturing capabilities allowing material property tailoring at a production rate up to one ton per day

Wood and Wood Composites

The University of Maine offers significant expertise across a variety of wood and wood-based composites. Rapid expansion of our capabilities to manufacture and analyze products over the past two decades has increased the breadth and scope of services offered through our world-class manufacturing and commercialization facilities. With capabilities in a variety of conventional and emerging wood-based composites technologies, our facilities provide unique opportunities for product improvement, new product development and product validation.

By working collaboratively with our experts, the University of Maine rapidly delivers accurate and effective results to solve our clients’ wood and wood-based composite challenges.

Examples of our wood and wood-based composite services include:

- Log conditioning and reduction systems which replicate production-scale processes

- Continuous furnish screening and drying processes which rapidly segment and generate desired wood characteristics

- Flexible spinning disk atomizing resin blenders which enable the evaluation of multiple resins and additive systems with precise control of loading and distribution

- Computer-controlled platen press systems which provide steam, electric and oil heated panel manufacturing of finished samples up to four by eight feet

- Dehumidification kiln and conditioning chamber systems which provide uniform moisture control in testing materials and finished goods

- Our ISO 17025 accredited-testing laboratory offers an extensive list of validated material and performance evaluations to determine the complete performance characteristics of our clients’ products, from micro- through macro-and large-scale assemblies.

Emerging Technologies

The University of Maine continually adopts technological advances in material science and product applications to provide our government and industrial clients cutting-edge manufacturing services from benchtop through pilot-scale. Our full suite of testing and analysis capabilities keep examinations of new products and formulations in-house, providing our clients a one-stop shop for their development needs.

Examples of our emerging technology services include:

- A full range of additive manufacturing capabilities to develop forest-based 3D polymer structures and assemblies quickly and effectively at end-use scale

- Forest-based biopolymers, bio-coatings and fiber-filled thermoplastic composites offering greener alternatives to traditional polymers

- Manufacturing, design and evaluation of mass timber structures (including cross-laminated timber, glulam and strand-based lumber) to create innovative large-scale panels, optimize system assemblies and define desired performance traits

- A complete biochemical and thermochemical biorefinery facility which generates forest-based biochemicals and biofuels from forest residues and wood waste, offering petrochemical replacements for a myriad of products

- In-house and collaboratively developed nanocellulose applications across a broad range of innovative end uses which allow for greener renewable product substitution in a variety of consumer goods

- Forest-based biomedical applications offering innovative and novel solutions to challenges in healthcare and patient treatment

Testing and Analysis

Our research and commercialization infrastructure delivers a diverse range of testing and analysis capabilities that essential to evaluating and understanding the performance of new and innovative products. The University of Maine continually updates and expands these testing capacities to provide quick and precise evaluations to our clients.

Examples of our testing and analysis services include:

- ISO 17025 accredited testing of wood and wood-based composite materials

- The only ALSC/PFI certified pellet testing laboratory in the Northeastern U.S.

- Micro- through large-scale static and cyclic mechanical testing capabilities, including modular multi-axis reactive testing of full-scale components and structures

- A full suite of thermal, chromatographic, microscopic and spectroscopic analysis technologies

- Complete testing services for all aspects of pulp, paper, coatings and wet chemistry

- Certified clean room facilities with state-of-the-art surface analysis equipment

- An array of environmental testing and accelerated weathering systems to quickly and repeatedly simulate a variety of outdoor and harsh environmental conditions

Engineering and Manufacturing Services

The University of Maine provides a broad range of in-house engineering and manufacturing solutions to meet the needs of our forest manufacturing clients. From design, analysis and optimization through manufacturing turn-key production systems, the university serves as a partner to increase client productivity, modernize processes and reduce manufacturing variability.

Examples of our engineering and manufacturing services include:

- Product, process and formulation research, development and optimization

- Design, manufacture and analysis of prototypes and pilot-scale short-run products

- Reverse engineering and comparative product evaluation

- Automation and turn-key systems design and integration

- Modern computer modeling and design, finite and stress analysis and rapid prototyping