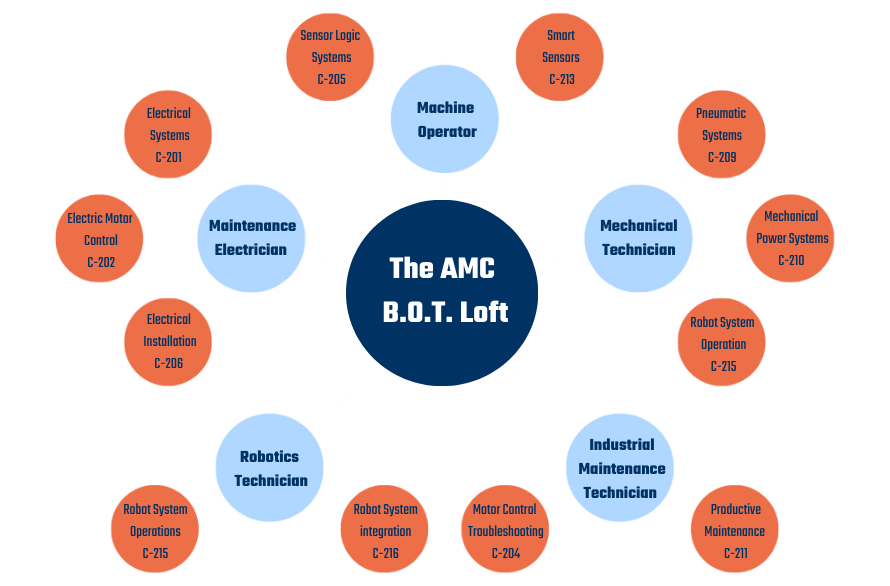

CHoose from 16 Micro-credential Offerings

Earn Saca Certifications at the AMC B.O.T. Loft

Our micro-credentials are designed to fast-track your skills in today’s most in-demand areas, including automation, robotics, smart manufacturing, and more. Whether you’re starting fresh, upskilling, or pivoting your career, these short, focused training programs offer hands-on learning and industry-recognized certifications through the Smart Automation Certification Alliance (SACA). These credentials help you stand out in the workforce.

3-Step Process

Knowledge

Earn your SACA Silver Certification and UMS Level 1 Micro-Badge

Begin with a self-paced Amatrol eLearning course, designed to fit into your schedule. When you’re ready, attend a proctored testing day at The AMC B.O.T. Loft to complete the official SACA Silver assessment.

Prove It

Earn your SACA Gold Certification and UMS Level 2 Micro-Badge

Join a cohort-based training session at The AMC B.O.T. Loft, where you’ll build real-world skills with hands-on equipment. This stage includes a practical skills assessment aligned to the SACA Gold standard.

Experiential

Earn your UMS Level 3 Micro-Badge and Full Micro-Credential

Put your skills to work, at work. You’ll complete a short written reflection, and your supervisor will verify your skill use and performance. This final stage connects learning to real impact—and awards you the full credential.

Discover UMS Pathways

At The AMC B.O.T. Loft , we believe in hands-on, skill based education that prepares you for the demands of today’s workforce. That’s why our training programs are designed to align with University of Maine System (UMS) Micro-credentials, which are portable, verified, and stackable digital credentials that demonstrate your expertise in real-world, high-demand areas like automation, robotics, and smart manufacturing.

As you move through a micro-credential pathway, you’ll progress through three levels of learning. In level 1, you’ll be introduced to foundational concepts and themes while preparing for more advanced training. Level 2 involves rigorous, industry-aligned training where you’ll practice key technical skills through workshops, boot-camps, online modules, or other formats. In Level 3, you’ll apply those skills in a real-world setting through internships, co-ops, or applied projects, receiving valuable feedback from industry mentors and partners. Once all three levels are completed, you’ll earn a UMS micro-credential: a digital, verifiable badge that’s easy to share on LinkedIn, your resume, or professional portfolio.

Micro-credentials earned at The AMC B.O.T. Loft not only help you build technical expertise but also give you the tools to communicate that expertise in a way that stands out. You’ll stay current with emerging technologies, gain meaningful experience, strengthen your digital identity, and open doors to new opportunities. Whether you’re a student, professional, or lifelong learner, The AMC B.O.T. Loft is your launchpad for skills that matter and credentials that count.

AMC B.O.T. LOFT example Micro-credential Pathways

At the AMC B.O.T. Loft, our micro-credential pathways are built to be flexible, customizable, and aligned with your goals. Whether you’re just getting started or aiming to advance, you can select a focus such as robotics, automation, or smart manufacturing. Training is structured in a hybrid format, combining online modules with hands-on, in-person experience. Each learner develops a personalized plan that supports their career path rather than conforming to a preset structure.

Select to learn more

C-201

Electrical Systems 1

Prepares individuals to connect, adjust, operate, troubleshoot, and analyze electrical circuits using basic electrical components: resistors, capacitors, inductors, DC motors, solenoids, manual switches, relays, fuses, circuit breakers, transformers, and indicators. Other key skills include: adhering to electrical safety rules, reading electrical circuit diagrams, applying Ohm’s Law and Kirchhoff’s Law, using digital multimeters, interpreting series/parallel circuits, and assessing power/circuit protection.

Electric Motor Control Systems 1

Prepares individuals to connect, adjust, and operate electrical motor control circuits using these electrical components: 3-phase AC motors, reversing magnetic motor starters with overloads, drum switches, control relays, timer relays, pushbutton switches, selector switches, limit switches, pressure switches, and float switches. Other key skills include: adhering to motor control safety rules, reading ladder logic circuit diagrams, checking for proper ground connections, wiring motors for high and low voltage, and interpreting common motor control application circuits.

C-202

C-203

Variable Frequency Drive Systems 1

Prepares individuals to connect, configure, adjust, and operate AC variable frequency motor drives using basic volts per hertz mode. Key skills include: adhering to VFD safety rules, operating VFD in manual using keypad, performing normal VFD startup and shutdown, performing emergency shutdown, viewing and editing parameters, changing speed with potentiometer, interfacing/configurating external discrete I/O, interpreting error codes, resetting drive errors, and configuring for acceleration, deceleration and braking.

Motor Control Troubleshooting 1

Prepares individuals to troubleshoot and remedy faults in electric motor control circuits and AC variable frequency drives. Skills include: adhering to troubleshooting safety rules, systems troubleshooting, component testing, and using digital multimeters, clamp-on ammeters, and PLC status indicators. Components include: AC VFD drives with volts per hertz capability, 3-phase AC motors, reversing magnetic motor starters with overloads, drum switches, control relays, timer relays, manual switches, limit switches, pressure switches, and float switches.

C-204

C-205

Sensor Logic Systems 1

Prepares individuals to connect, adjust, and operate discrete (on/off) electronic sensors and relay control sequence circuits using these components: inductive sensors, capacitive sensors, magnetic reed sensors, photoelectric sensors, hall effect sensors, limit switches, control relays, timer relays, manual switches, DC motors, indicators, electro-pneumatic solenoid directional control valves, and pneumatic actuators. Other key skills include: selecting sensor type for an application, reading ladder logic circuit diagrams, and interpreting common relay-control sequence applications circuits.

Electrical System Installation 1

Prepares individuals to install and test/commission electrical motor control circuits using these electrical components: control cabinet enclosures, 3-phase AC motors, reversing magnetic motor starters with overloads, control relays, timer relays, pushbutton switches, selector switches, limit switches, pressure switches, indicators, electro-pneumatic solenoid valves, safety disconnect switches, and circuit protection. Key skills include: adhering to motor control installation safety rules, using proper PPE, reading electrical wiring installation diagrams, sizing circuit protection, installing components on DIN rails and cabinet panels, installing and testing ground systems, wiring motors for high and low voltage, selecting and preparing wire for installation, attaching of wire to terminal strips and components/motors, and routing of wire with raceways/conduits.

C-206

C-207

Programmable Controller Systems 1

Prepares individuals to program, configuration, adjust, monitor, and operate industrial programmable logic controller (PLC) systems. Key skills include: adhering to PLC safety rules, performing normal startup/shutdown, operating PLC in different modes, performing emergency shutdown and reset, monitoring for proper operation through indicators and PC-based PLC software, configuring processor software drivers for communication to PC, configuring and loading of HMI programs, operating HMI with PLC, configuring PLC discrete I/O, transferring programs between PC and PLC processor, interpreting basic and intermediate level PLC ladder logic programs (with contacts, coils, timers, counters, math, comparison instructions), PLC project creation/editing, and interpreting common PLC program logic applications using electro-pneumatic actuators and on/off motor control systems.

Programmable Controller Troubleshooting 1

Prepares individuals to troubleshoot and remedy faults in programmable logic controller systems. Skills include: systems troubleshooting and component testing using digital multimeters, PLC software, and PLC status indicators. Components include: PLC power supply, power distribution system, processor module, discrete input and output modules, chassis, and discrete field I/O devices. Troubleshooting applications include: multi-step machine sequence logic programs using electro-pneumatic actuators and on/off motor control systems.

C-208

C-209

Pneumatic Systems 1

Prepares individuals to connect, adjust, operate, and analyze pneumatic circuits using these components: quick connect fittings, tee and cross fittings, air compressors, filters, regulators, lubricators, gauges, rotameters, directional control valves, flow control valves, check valves, cylinders, and motors. Other key skills include: adhering to pneumatic safety rules, reading pneumatic circuit symbols and diagrams, applying the Force-Pressure-Area formula, converting absolute/gauge pressure units, performing reciprocating compressor startup/shutdown, applying Pascal’s Law, setting pressure switch, filter draining, setting lubricator rate, lubricator refilling, and measuring delta P.

Mechanical Power Systems I

Prepares individuals to install, adjust, align, tension, operate and analyze basic mechanical power transmission drive systems using these components: motors, shafts, flexible jaw couplings, fractional horsepower (FHP) chain drives, FHP v-belt drives, spur gear drives, pillow block bearings, and flange bearings. Other key skills include: adhering to mechanical drive safety rules, mounting and leveling motors, testing and correcting for soft foot, installing components and shafts with keyways, sizing keys, aligning shafts using feeler gage and straight edge method, calculating speed and torque from component size ratios, interpreting rotary power specifications, determining mechanical efficiency, greasing bearings using a grease gun, refilling oil lubrication reservoirs, interpreting lubrication specifications, and identifying component given a model number.

C-210

C-211

Industry 4.0 Total Productive Maintenance

Prepares individuals to perform maintenance in a production environment where Industry 4.0 technology is used. Key skills include: interpreting maintenance work orders, receiving/responding to maintenance work orders via mobile/cloud technology, using a cloud-based maintenance management system to maintain and analyze process or machine history, performing preventive maintenance schedule with electronic record keeping, cleaning machines, lubricating and adjusting machines, calculating overall equipment effectiveness (OEE) and machine downtime, identifying methods of reducing downtime, and using basic troubleshooting methodologies to find root causes.

Ethernet Communications 1

Prepares individuals to connect, configure, monitor, and operate basic Ethernet networks in an Industry 4.0 environment. Key skills include: interpreting IP addresses, setting IP addresses (PCs, PLCs, robots, and other machines), connecting devices to an Ethernet network, setting up and configuring a basic managed Ethernet switch that uses layer 2 technology, connecting an Ethernet network in a star topology, configuring a managed switch subnet, identifying type of topology given a diagram, configuring a network for static and dynamic addressing, monitoring and interpreting status indicators on switch, viewing managed Ethernet switch network performance and diagnostics via software, and configuring port security of a managed switch network.

C-212

C-213

Smart Sensor and Identification Systems 1

Prepares individuals to connect, configure, adjust, program, monitor, and operate smart sensors (analog pressure/ultrasonic, photoelectric, and stack light), barcode readers, and RFID readers in an Industry 4.0 environment. Key skills include: connecting sensors to Ethernet network through IO-Link Masters or directly, configuring IO-Link Masters, interpreting sensor and IO-Link Master status indicators, downloading IODD and EDS files for smart sensors, wiring smart sensors, configuring PLCs to receive data from smart sensors through network, monitoring health of sensors through network, programming RFID tags or printing barcode labels, setting up and operating RFID readers, configuring RFID/barcode readers to communicate to a PLC, configuring Ethernet-serial converter to communicate sensor data to PLCs, and programming PLCs to use smart sensor/RFID/barcode data to perform common process applications.

Smart Factory Systems 1

Prepares individuals to set up, adjust, configure, program, interface, monitor, and operate smart factory systems that use Industry 4.0 technology to efficiently produce high-quality products in these applications as an integrated system: pick and place, gauging, indexing, sorting and queuing, and robotic assembly. Components used shall include: DC-motor belt conveyors, ball screw linear drives, electro-pneumatic actuators/valves, vacuum parts pickup, vacuum switches, electronic sensors, clutch, stepper motors, and servo robots. Other key skills include: adhering to smart factory safety rules, configuring and interfacing PLC and robot controllers via Ethernet/IP and discrete I/O handshaking, using Ethernet message instruction to perform controller-to-controller handshaking, and programming/operating a multi-station production process.

C-214

C-215

Robot System Operations 1

Prepares individuals to set up, adjust, monitor and operate industrial robot systems in an Industry 4.0 automation environment. Key skills include: adhering to robot safety rules, identifying robot types and robot components (and end-effectors), performing normal startup and shutdown, performing emergency shutdown and recovery, identifying robot work envelope, performing robot safety inspection, using teach pendant to view menus and status indicators, using teach pendant to jog robot in joint mode or using Cartesian coordinates, adjusting jog speed, setting and testing robot joint travel limits, using teach pendant to identify robot position in each of 5 frames, defining a frame using 3-point method, loading a robot program using Ethernet or memory card, testing digital robot inputs and outputs, testing robot program in single step or continuous mode, selecting and running robot program using teach pendant, teaching/adjusting robot points using proper frame, identifying/recovering from a fault, and viewing/interpreting robot alarm history.

Robot Systems Integration 1

Prepares individuals to program, interface, and optimize industrial robot systems in an Industry 4.0 automation environment for these applications: pick and place, basic assembly, machine load/unload, and gluing. Key skills include: interpreting robot programs, developing robot sequence operations and robot program for an application, entering robot programs and points using a teach pendant, interfacing on/off input sensors and solenoid output devices to digital I/O of robot, interfacing digital I/O of robot to PLC, and cycle time optimization. Programs commands include: 3 types of motion, speed, offset, data register, branching, digital I/O, looping, waiting, and macros.