Off-Road Wheelchair

OFF-ROAD WHEELCHAIR

ABOUT THE PROJECT

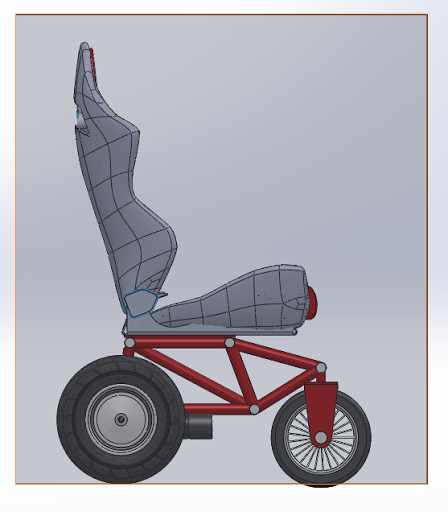

Over the course of the next two semesters, our team will be working alongside the O’Brion family to design and build a fully electric motorized off-road wheelchair for Cody O’Brion. Cody suffered a brain injury as a child, and has been confined to a wheelchair with very limited mobility. Cody and his family enjoy spending time in the outdoors, but over the years have struggled to find an efficient means to do so. The wheelchair will allow the family to bring Cody to new and exciting areas. The fall semester will consist of the design process, which will be followed by the fabrication process in the spring semester. During this time, our team will be responsible for raising the funds, and acquiring all the necessary materials to complete the project. We will be consulting with professional engineers throughout the design and fabrication process to ensure the wheelchair is a safe and made to the highest quality. We strive to develop a safe and efficient wheelchair that will meet all of Cody’s, and the O’Brion family’s needs.

DESIGN CRITERIA

This project is to design and fabricate an electrically operated and motorized wheelchair that is design specifically for the assisted mobility of handicapped personnel who are unable to physically and/or mental propel themselves. The design will be created with the O’Brion family in mind. The wheelchair is to be design to have the ability to negotiate terrain which is present in woodland trails. These woodland trails will be defined as an unimproved dirt roads which may consist of obstacles such as roots, potholes, mud, rocks, vegetation, bridges and prolonged elevated grades. The chair is designed to be operated by a second party who will be walking behind the chair, and it will allow for that individual to give minimal physical effort to operate the system. In the event that that chair is moving over level ground or even over a decline the second part should maintain the ability to push the chair with minimal resistance.

SAFETY:

The number one goal for the proposed design is to keep safety in mind. The wheelchair will be required to provide specific safety criteria as specified by the O’Brion family. The family has requested the following:

- The wheelchair must only have a maximum speed of 5 mph and is to be controlled from behind by the operator.

- There will be an optional control to allow the passenger to operate the system (with no control of speed and limited to only forward movement) which can only be engaged by the operator.

- The wheelchair will be required to have lights for times of limited visibility and the lighting system must be on an independent circuit powered by its own independent power source to not draw additional power during system operation and compromise battery life or decrease overall system power.

- The wheelchair is required to have an emergency kill switch which will immediately disable mobility of the system.

- There must be a restraint system in place to secure the passengers.

- The wheelchair must have a reliable and efficient braking system. This must also be tied into the emergency stop button. There should be a primary and contingency means for stopping the system, one electrical and one mechanical

DIMENSIONAL CONSTRAINTS:

- The wheelchair needs to be designed so that it has the ability to be transported by vehicle.

- The entire wheelchair must not exceed a width of 30 inches, a length of 49 inches or a height of 56 inches.

- The wheelchair needs to be designed to be able to withhold a passenger’s with a weight of 150 pounds. We plan to design the wheelchair to move much more weight than that.

COMFORT:

- Because the families plan for using this wheelchair is on outdoor trails they would like us to ensure that the chair is comfortable.

- The chair will need to have an ergonomic seat design and have a comfortable backrest angle, if not adjustable.

- The wheelchair must be designed to be loaded from the right side (as if you were seated) and must incorporate a passenger loading assistance system.

- Finally and probably the most challenging will be to design the chair to incorporate a suspension system for the seated passenger to allow them to be able to ride comfortably over potholes, rocks, roots and other areas which would otherwise cause for an uncomfortable ride.

OPERATION AND MAINTENANCE:

- A considerable amount of the system design will be determined by the parts in which it is built from.

- The wheelchair needs to be built with standardized parts when available to help with long term operation and maintenance.

- The parts that cannot be standardized must be design so they will not fail which would cause stop the system from running.

- Cost needs to be in mind for all future repairs needed and all maintenance which needs to be conducted.

- The components of the system that will be specified to fail over a specified period of time (i.e. batteries) must be annotated and information on acquiring new parts needs to be available.

WEEKLY BLOG

29NOV2015- Our team has run its preliminary FEA analysis to determine where our maximum deflections will occur. This will allow us to see where we will need to add additional support, or possibly change the design to limit the deflection and stress. We will also be adding more components to our solid model, which will allow us to develop our design further, and get exact dimensions. These dimensions will be used to build our wheelchair, and allow for us to calculate the stresses and forces on our wheelchair more accurately.

22NOV2015- Our team will focus on verifying our design is strong and safe. We will be determining forces and stresses our wheelchair will encounter while on the trail. This will allow us to determine a height, width, wall thickness, and material for our frame. We are striving to make the wheelchair as light as possible, but want to ensure it will be able to hold up to the rigorous terrain that will be found off-road. We will also be able to determine where our maximum stresses will occur, and will be able to add appropriate bracing.

15NOV2015- This week we will be drawing our initial design, with the main drive system components mounted. We will also finalize all calculations to determine the appropriate size of the motors. Research has begun for programming the motors and controllers, and looking at all the various electrical components. We will continue to investigate modifying existing chairs to support all-terrain use. Our search for donations is constantly evolving, and will be in contact with vendors regarding possible component donations.

08NOV2015- Our team met with an engineering mentor this week to help the initial design and schematic of our motors and controls. We also are researching our different battery options to find the option that best fits our clients needs. A few of the determining factors will be weight, battery life cycle, amp hours, and charging abilities and characteristics. We have identified several chairs that will provide comfort and safety to our clients, and will be visiting local vendors to personally test different types of seats.

01NOV2015– We will be finalizing our initial frame concept this week. We are determined to make the frame as light and strong as possible. We are interested in using 6061-t6 aluminum as a material to construct the wheelchair frame.

25OCT2015– We have focused our early semester weeks focusing on researching various components of electric wheelchairs, including motors, suspension,battery,controls,frames, and seats. We will be selecting components in the following weeks.

18OCT2015– Our group met with our professional engineer mentors this week to discuss our initial concept ideas. We will be in contact with our mentors frequently. This will ensure we are designing and fabricating the safest possible wheelchair. The off-road terrain will subject the wheelchair more rigorous forces, and we want to make sure our design will hold up in all conditions to keep Cody and his family safe.

MEET THE TEAM

I was raised in Frenchville Maine and attended high school in Madawaska Maine. After graduating I joined the Army and served four years Active Duty with the 82nd Airborne as a Combat Engineer, and Deployed to Afghanistan to fight for Operation Enduring Freedom. I started college in the spring of 2012 at the University of Maine, Orono, ME where I study Mechanical Engineering Technology. I began working an Internship at the Advanced Structures and Composites Center during that first fall semester. I spent three years helping with development of Offshore Floating Wind, and am now working to help launch a Thermoplastics manufacturing facility within a new building expansion. I am a member of the Senior Skulls Honor Society which allows me to be a representative of the college on behalf of the entire student body. I am also the President of Engineers Without Borders and have just submitted to begin a new program in Ecuador.

Engineering has been a passion of mine since I was very young. In high school, I attended a technical school in Massachusetts called Tri-County, where I took engineering classes during my four years there. I am currently a senior in the Mechanical Engineering Technology program at the University of Maine. I have interests in Computer Aided Manufacturing (CAM) and robotics. When I have free time, I enjoy using design software, and my 3D printer to design and make my own projects.

I was born and raised in Portland, ME, and graduated from Cheverus High School in 2010. I am a senior in mechanical engineering technology. I joined the Maine Air National Guard in April of 2013, where I am trained as a welder and machinist. I have always enjoyed working with my hands on trucks, snowmobiles, and anything else that has a motor, this passion led me to pursue a degree in MET. Outside of school I enjoy hunting, fishing, hiking, and spending time at our family camp.

I am currently a senior at the University of Maine at Orono pursuing a degree in Mechanical Engineering Technology. I am from Basking Ridge, New Jersey. I have experience from interning at Thomas Manufacturing in Jersey City and also at the Advanced Manufacturing Center, University of Maine, Orono, ME. Some of my interests outside of school include scuba diving, fishing, reading, volunteering at animal shelters.

SPONSORS AND DONORS

-MAINEiacs Charities was founded in 1981 as the charitable arm of the Maine Air National Guard; with the mission of giving back to the communities we serve. We are staffed entirely by volunteers, meaning that 100% of net proceeds we receive are used to achieve our mission. Over the past 34 years, MAINEiacs Charities has provided both financial and non-financial support to the members of the Maine National Guard and their families, area Project Graduations, the Children’s Miracle Network, Veterans’ Homeless Shelter, numerous civic groups ranging from the Boy and Girl Scouts to Big Brother/Big sister and the Maine Veterans Homes along with individuals in need throughout our communities.

POC for this webpage is:

Michael O’Brion

Michael_Obrion@umit.maine.edu

Mechanical Engineering Technology

5711 Boardman Hall

Orono, ME, 04469