GE Ergo-Handmill

Project Overview

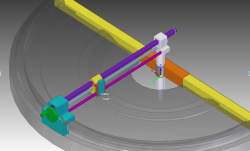

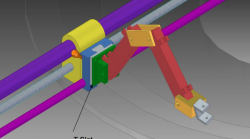

Early this semester, General Electric of Bangor, Maine came to us with an issue that was offered to the University of Maine Mechanical Engineering Technology to solve. GE has requested a devise that would hold a hand held grinding tool to reduce strain on its welders. The part that is being machined is referred to as a steam diaphragm, which houses static air foils that direct steam as it enters the turbine. These foils in the diaphragm become worn and pitted over time. They are then sent back to GE for the blades to be repaired, and here is where our product comes into the picture. To remove the damaged sections of foil, a hand mill is used, and being hand operated it puts a lot of strain on the welders repairing the part. The Ergo Handmill will dampen the shock from the tool and keep the welder at an upright, ergo friendly position while removing material, while being simple and easy to operate.

Criteria/ Constraints

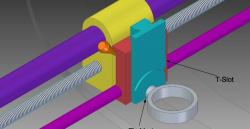

The parts that are being repaired are quite unique to each other. This apparatus must be able to adapt to different dimensions and features one each diaphragm. Angles on the inner and outer diameter of each foil must be adapted to. Inner and outer diameters or the diaphragm arch are specific to each as well. The final product will be modular with no section weighing in excess of 25 pounds.

Concepts

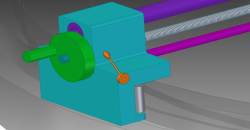

After two meetings with GE on refining our concept designs, we have gone from 5 designs and are now refining a single, most favored design of those original 5. This latest concept will be supporting 3 separate attachments that will hold the handbill that together will cater to any single diaphragm that comes in for repair.

Future Work

Upon completion of the fall semester, the team has projected to have developed a final design before enter the prototyping phase. None the less, the deign is a living and breathing concept that will evolve throughout the prototyping process and testing phases.

Weekly Update

This week, the final concept design is being developed to be more adaptive, stable, and versatile. More stabilizing rails are being incorporated, a second mount is being added, and 3 handmill chucks are being designed to handle any situation.

Meet the Team

Jacob Hallgren

Jacob is a Senior in Mechanical Engineering Technology at the University of Maine. He is the webmaster for this team. He plans to pursue a career in power generation via steam/gas turbine. He enjoys studying thermodynamics and renewable energy. He is also a member in the Maine Army National Guard. He will be commissioning as a 2nd Lieutenant in May of 2016 into B Co- 3/172 IN (MTN) where he currently serves as a simultaneous membership program cadet whilst in Army ROTC at the University.

Caleb Farley

Caleb is a senior in the University of Maine’s Mechanical Engineering Technology program. He has worked for Somic America as a Suspension Line machine operator, and manufactured parts for the Toyota Camry, Rav4, and Venza. He hopes to work for Somic America as a Suspension line engineer after graduation from the University of Maine. In his free time he enjoys hunting, fishing and following his favorite Boston sports teams.

Sean Teixeira

Sean is a fourth year student at the University of Maine Orono pursuing his B.S. degree in Mechanical Engineering Technology. For the past year and a half he has worked for Global CNG at a natural gas compression station operating the site and preforming billing and dispatching duties. He graduated from Morse high school in 2012 in Bath, ME. He immediately begin attending the University of Maine after high school and is graduating in December of 2016.

Richard Lafreniere

Richard is a 4th year Mechanical Engineering Technology student at the University of Maine in Orono. For two years he has worked in the Machine Tool Lab as a Tool Crib Attendant and has experience as a Teaching Assistant in the shop. He was raised in Oakland, Maine and graduated from Messalonskee High School in 2009. In 2012 Richard enrolled in the MET program at the University and is expecting to graduate December 2016. His hobbies include working on vehicles, snowboarding, snowmobiling and projects around the house.

Connor Jensen

Connor is a senior in the University of Maine’s Mechanical Engineering Technology program. He has worked for JR Higgins Associates as a CNC operator and School Bus sign assembler. He achieved the rank of Eagle Scout and graduated from Westford Academy in the spring of 2011. In the winter he enjoys working at Nashoba Valley Ski Area as a ski patroller.