Skin Conductance Sensor - H.A.L.O. Mk. 1

The major differentiating factor between heat exhaustion (the body’s response to high temperatures) and heat stroke (a deadly form of overheating) is the presence of bodily perspiration. Whether it’s extinguishing wildfires with aerial firefighting or poor hydration, pilot’s are susceptible to overheating which can inhibit the ability to fly safely. Monitoring body temperature and detecting the presence of sweat is critical to ensuring the pilot is not suffering from heat stroke.

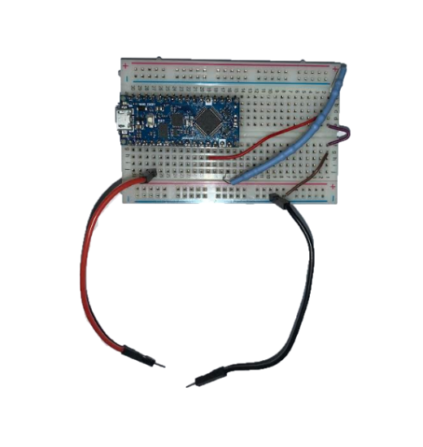

Pictured above, the skin conductance sensor consists of two wire probes that act as electrodes placed across the pilots forehead. A voltage divider circuit in parallel with a 3MΩ resistor is connected to an Arduino processor that is able to determine the presence of sweat based on the voltage measured across the electrodes. In a future prototype, these wire probes would be covered with a conductive material to ensure the pilot is not poked with the wires.

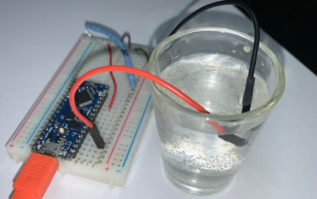

To test the device, the probes were submerged at various time intervals within a saline solution to simulate the conductivity of sweat. Removing the probes from the saline solution simulated non-sweating conditions as this disrupts the conductive path between the two probes. The binary condition of 0 for not sweating and 1 for sweating was assigned to the resulting data points, and conditions were recorded every minute for 20 minutes. The sweating simulation can be seen to the right.

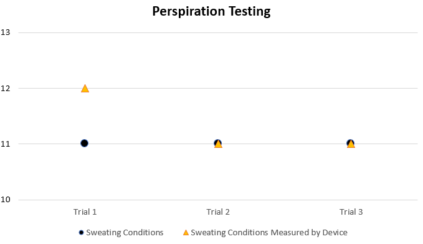

After using a random number generator to assign the sequence of sweating conditions, the skin conductance sensor proved to be quite accurate as seen with the overlapping data points to the left. For Trials 2 and 3, the device recorded all conditions that represented sweating. For Trial 1, the device erroneously recorded one extra condition of sweating. Averaging the device data and comparing it to the actual number of sweat conditions yielded a percent error of 3.03%.