Papermaking

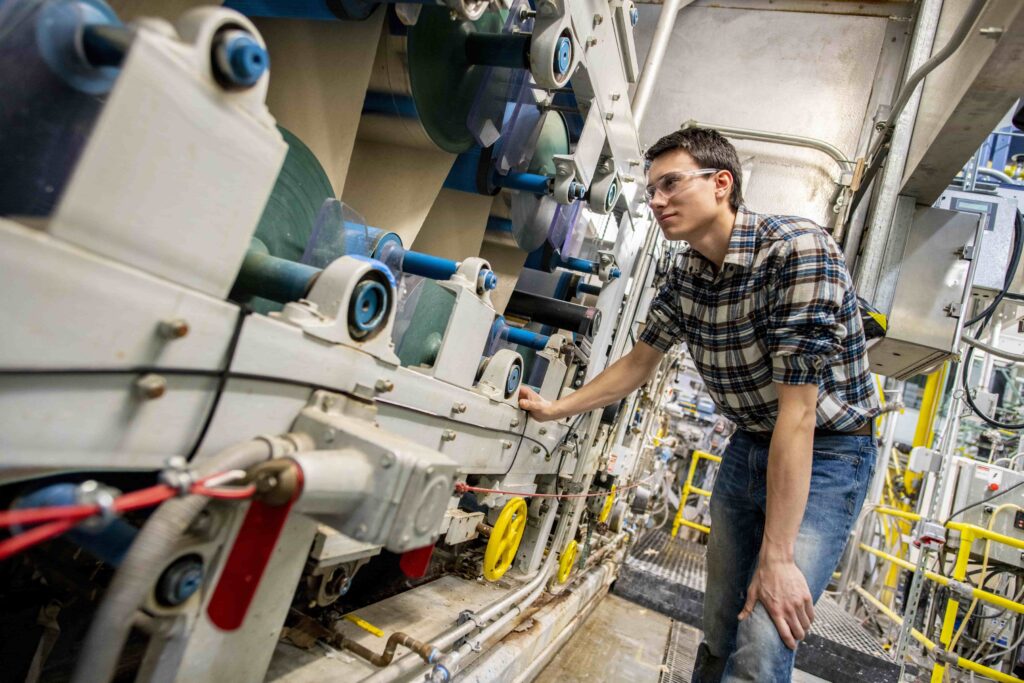

PDC’s pilot paper machine is available for raw material and process operation studies. The paper machine may also be used to evaluate equipment components. Steady state is reached in less than thirty minutes, allowing multiple trials in a single day. Come work with us, or let us make your paper for you.

The PDC’s pilot paper machine is capable of several processes, including complete equipment analysis, raw material studies, and process operation studies.

Specifications

- Basis weight range: 25-220 g/m2

- Average production rate: 1 lb/min

- 10-100 fpm

- 13″ trim

Equipment List

- 6-slice dilution headbox with Holey roll

- Close white water system with on-line suspended solids and charge monitoring for highly efficient wet-end chemical studies

- Two felted press nips with a separate embossing nip for specialty applications

- Upgraded size press

- Versatile size press coating supply system

- In-line, multi-nip steel-steel calendar stack

- High precision drive system

- Honeywell Experion MX scanner with on-line monitoring of basis weight, moisture, caliper, and ash, in both the machine and cross-machine direction

- Unwind stand to enable size press/coating experiments using customer supplied base paper rolls

The Power of Dynamic Formation

Unlike conventional static sheet formers, the Canpa unit replicates the high shear forces and dynamic drainage conditions found on a full-scale commercial paper machine. This ensures that the handsheets produced are highly representative of production-level materials, minimizing the risk and cost associated with scaling up new formulations.

Key Features & Capabilities

- Commercial-Relevance: Produces sheets that closely mimic full-scale machine conditions, including velocity and fiber orientation effects, which are vital for predicting material performance.

- Precision Control & Speed: Features automatic, repeatable control over key variables for consistent results. The system is also capable of forming multiple layered sheets and achieves a high throughput of 4-8 sheets per hour.

- Sample Quality: Produces consistent, large 12.5” X 38” large hand sheets in a controlled laboratory environment suitable for detailed physical and structural analysis. Sheets undergo integrated pressing, followed by restrained drying for superior consistency.

Integrated Support and Advanced Processing

Beyond the core forming process, the PDC offers comprehensive services to support your entire research project:

- Expert Operation: The equipment is operated by our experienced staff to ensure optimal results and process reliability.

- Furnish Preparation: We provide pulp refining services to precisely prepare the furnish to your specifications.

- Advanced Materials: We have the unique ability to produce handsheets with up to 100% Cellulose Nanofibrils (CNF), enabling advanced material development.

Versatile Applications

The equipment is ideal for testing and optimizing a wide range of materials and formulations:

- Traditional Grades: Research on standard paper grades (fine paper, linerboard, specialty paper).

- Next-Gen Materials: Testing Specialty Fibers such as Cellulose Nanofibrils (CNF), Microfibrillated Cellulose (MFC), and synthetic fibers.

- Advanced Products: Use in developing non-wovens and composites, focusing on fiber distribution and bonding.

This extensive capability allows users to optimize formulations and gain deeper insights into how different fibers interact under dynamic conditions.

Accelerate Your Research

Leveraging the Canpa Dynamic Sheet Former at the UMaine PDC allows you to:

- Reduce Scale-Up Risk: Get accurate, predictable results early in the development cycle.

- Optimize Formulations: Rapidly test and refine changes to fiber blends, additives, and chemistries.

- Analyze Fiber Dynamics: Gain deeper insights into how different fibers interact under dynamic conditions.

- Process Challenging Stocks: Effectively dewater difficult-to-dewater stocks

Book Your Trial Today

Partner with the University of Maine PDC to move your fiber research from concept to commercial reality faster.

Contact: james.hargreaves@maine.edu

A size press is an option in the operation of the pilot paper machine. This sophisticated piece of equipment allows for the addition of surface sizing, as well as a light coating on the base sheet. Our upgraded size press allows for a wide range of coating and surface treatments to be applied, such as silicone and barrier coatings, and therefore, expand the types of high-value, specialty paper, and composite prototypes that can be produced. In addition, the new module significantly improves efficiency and reduces the time required to produce prototypes for market testing.

Equipment details:

- Rapid change-over size press coating supply system to evaluate multiple variables in a condensed timeframe.

- Unwind stand to enable size press experiments using customer supplied base paper rolls

- Comprehensive sheet sampling (pre- and post-size press) for accurate pick-up data

- Rods engineered for 0.5-4.5 gsm applications

- Integrated temperature control to ensure consistency across every run

- Steady starch inventory and specialty types sourcing available for upon request

- Capable of applying both high and low solids coatings over a wide range of rheology

The Wet End Process Simulator (WEPS) from Sam Bo Scientific is specially designed to investigate the effects of raw material variation and chemical additives on paper quality, drainage, retention, and uniformity by replicating a paper machine or fiber thermoforming machine under vacuum dewatering and vibration.

The WEPS can be used for controlling and setting new chemicals, testing new wires, identifying additive problems and developing new paper products. The unit enables tight control on suspension shearing intensity, additives’ contact time optimization and drainage conditions, and produces sheets that have technical characteristics closely related to actual machine-made papers.

Sheet Formation Specifications

- Diameter: 190mm

- Basis weight: 20-350g/sqm

- Formation tank volume: 750-1800mL

- Vacuum range: max. 350mmHg

- Forming wire: User selectable 60-200 mesh

- Solid matter consistency: 0.1-1%

Sheets can be tested for TAPPI standard physical properties.

Coating

The PDC routinely works with clients to improve product properties and lower costs by formulating and applying coatings to their products. Coating a thin layer of material on the surface of paper, film, foil, or composites is a very effective method of adding functionality and value to a product. Printing papers, paper cups, grease-resistant food packaging, and high-strength composites all benefit from quality coatings. For applying coatings, the PDC has a bench drawdown coater as well as a Faustel Labmaster coater.

Faustel Labmaster Coater

Coating application is one of the most important steps in making paper, foil and other materials, and the PDC is now able to coat commercially made basepapers or specialty basepapers produced on our pilot paper machine using a variety of methods. The Faustel Labmaster coater offers a versatile range of coating applications for papers, films, foils, non-wovens, and specialized composite materials.

The pilot coater has flexible, three-roll coating configurations for:

- Direct or offset gravure

- Direct or offset smooth roll

- Mayer rod coating

- Kiss coating

- Bent or bevel blade

Some of the pilot coater’s other features include:

- Trailing blade or rod coating

- Web processing at up to 12 inches in width

- Speeds up to 100 fpm

- Non-contact, hot air drying

- Fully equipped laminating station

Calendering

Calendering improves printing properties, particularly roughness and gloss. The values attained depend on the speed, pressure, and temperature of calendering, the properties of the base sheet, the average moisture content, and the composition of the coating. The options available for calendering include:

On-line calender stack

- Steel-nip

- Not heated

- Runs on either base stock or paper produced on the pilot paper machine

Off-line calender stack

- Either sheet or roll feed

- Runs on a conventional or hot, soft-nip configuration

- Maximum loading: 18,000 pounds, 1500 PLI with 12″ web

- Top roll: 9″ diameter x 12″ face – SUPERTEX-HC, temperatures < 250F

- Center roll: 9″ diameter x 12″ face – hardened chrome plated, heated steel roll, max. temperature = 600F

- Bottom roll: 9″ diameter x 12″ face – steel roll, max. temperature = 600F

- Variable speed: 4-45 fpm

Capabilities

- Evaluation of base stock/coating interactions

- Development and evaluation of innovative barrier coatings

- Evaluation of coating additives, including bio-based polymers

- Determination of coating structure/property relationships

- Determination of physical-chemical interactions between paper surface and inks

- Evaluation of variables affecting gloss development following calendering

- Off-line rewinding/slitter

- Off-line sheeter

- Off-line guillotine

To begin working with us, visit our Working with the PDC page.