Fiber Thermoforming

Kiefel Technology Thermoforming

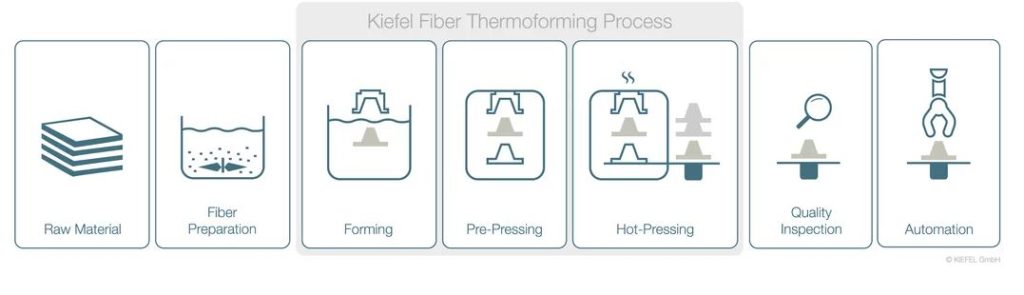

The PDC partnered with Kiefel Packaging to install Kiefel’s lab-scale unit.

Kiefel packaging’s commercial NatureFormer KFT90 unit uses a suction process in combination with cold pre-processing technology to produce the residual moisture to approximately 60%. The final pressing is accomplished with a heated tool that lowers residual moisture to approximately 7%. Bring your feedstocks and recipes to run trials, or work with the PDC to product or source needed materials.

Dry Thermoforming

The PDC has installed a lab-scale Gralex Thermoformer for drying thermoforming applications.

This lab-scale dry thermoformer is used to press, mold, and crease paperboard into 3D shapes, primarily food packaging. These shapes include paper plates, trays, and bowls. This equipment is an important step in our Sustainable Packaging Initiative.

If you are interested in learning more about our thermoforming units, please contact Colleen Walker at: colleen.walker@maine.edu