Research

Research

Our team of experts is developing and optimizing the production and integration of bio-based materials and next-generation manufacturing systems into mainstream manufacturing to achieve net-zero carbon emissions.

Sustainable Materials Development & Optimization

Developing renewable, low-cost, high-performance feedstocks to replace fossil fuel-derived materials for advanced manufacturing applications.

REDUCE CARBON FOOTPRINT

Our team is at the forefront of developing sustainable materials that cost less and require significantly less energy to produce. For example, we have reduced the energy needed to produce some of these materials by 44%, further reducing their carbon footprint by almost half.

HIGH PERFORMANCE BIO-BASED MATERIALS

We are improving the performance of bio-based materials to match or exceed the mechanical properties of similar fossil-fuel derived materials. For example, some of these bio-based composites show significant improvements in tensile strength and modulus, by 5.4% and 29.8%, compared to traditional materials.

LOWER COST

Through new methods and material innovations, we are creating low cost, sustainable composites that are cost-competitive with traditional materials.

Major Accomplishments

- Designed tailorable water-based chemistries to surface modify cellulose materials and improve biobased composite strength and modulus for specific polymers (PLA, PETg, PBS), these methods are currently being scaled up to produce improved feedstock for 3DP applications.

- Developed new co-spraying methods for producing dry particles of mixed- or coated-cellulose with thermoplastic materials. The thermoplastic-coated cellulose can be directly molded into various products or compounded with other thermoplastic matrices with improved interfacial properties of cellulose, leading to better dispersion/distribution of cellulose in matrices.

Related Publications

- Meng X, Bocharova V, Tekinalp H, Cheng S, Kisliuk A, Sokolov AP, Ozcan S et al. Toughening of nanocelluose/PLA composites via bio-epoxy interaction: Mechanistic study. Materials & Design. 2018;139:188-97.

- Meng X, Nguyen NA, Tekinalp H, Lara-Curzio E, Ozcan S. Supertough PLA-silane nanohybrids by in situ condensation and grafting. ACS Sustainable Chemistry & Engineering. 2018;6(1):1289-98.

- Li K, Skolrood LN, Aytug T, Tekinalp H, Ozcan S. Strong and tough cellulose nanofibrils composite films: Mechanism of synergetic effect of hydrogen bonds and ionic interactions. ACS Sustainable Chemistry & Engineering. 2019;7(17):14341-6.

- Li K, Wang Y, Rowe M, Zhao X, Li T, Tekinalp H, et al. Poly (lactic acid) toughening through chain end engineering. ACS Applied Polymer Materials. 2019;2(2):411-7.

- Li Y, Zhang Y, Goswami M, Vincent D, Wang L, Liu T, Ozcan S, et al. Liquid crystalline networks based on photo-initiated thiol–ene click chemistry. Soft matter. 2020;16(7):1760-70.

- Meng X, Scheidemantle B, Li M, Wang Y-y, Zhao X, Toro-González M, Ozcan S et al. Synthesis, characterization, and utilization of a lignin-based adsorbent for effective removal of azo dye from aqueous solution. ACS omega. 2020;5(6):2865-77.

- Sinquefield S, Ciesielski PN, Li K, Gardner DJ, Ozcan S. Nanocellulose dewatering and drying: current state and future perspectives. ACS Sustainable Chemistry & Engineering. 2020;8(26):9601-15.

- Wang Y, Li K, Zhao X, Tekinalp H, Li T, Ozcan S. Toughening by nanodroplets: Polymer–droplet biocomposite with anomalous toughness. Macromolecules. 2020;53(11):4568-76.

- Zhao X, Li K, Wang Y, Tekinalp H, Larsen G, Rasmussen D, et al. High-strength polylactic acid (PLA) biocomposites reinforced by epoxy-modified pine fibers. ACS Sustainable Chemistry & Engineering. 2020;8(35):13236-47.

- Zhao X, Li K, Wang Y, Tekinalp H, Richard A, Webb E, Ozcan S, et al. Bio-treatment of poplar via amino acid for interface control in biocomposites. Composites Part B: Engineering. 2020;199:108276.

- Bhagia S, Bornani K, Soydan Ozcan D, Ragauskas AJ. Terephthalic Acid Copolyesters Containing Tetramethylcyclobutanediol for High‐Performance Plastics. ChemistryOpen. 2021;10(8):830.

- Cao D, Li Q, Sun X, Wang Y, Zhao X, Cakmak E, et al. Amphipathic Binder Integrating Ultrathin and Highly Ion‐Conductive Sulfide Membrane for Cell‐Level High‐Energy‐Density All‐Solid‐State Batteries. Advanced Materials. 2021:2105505.

- Copenhaver K, Li K, Lamm ME, Walker C, Johnson D, Han Y, et al. Recycled Cardboard Containers as a Low Energy Source for Cellulose Nanofibrils and Their Use in Poly (l-lactide) Nanocomposites. ACS Sustainable Chemistry & Engineering. 2021.

- Lamm ME, Li K, Qian J, Wang L, Lavoine N, Newman R, et al. Cellulose Nanofiber Templating: Recent Advances in Functional Materials through Cellulose Nanofiber Templating (Adv. Mater. 12/2021). Advanced Materials. 2021;33(12):2170094.

- Li K, Clarkson CM, Wang L, Liu Y, Lamm M, Pang Z, et al. Alignment of Cellulose Nanofibers: Harnessing Nanoscale Properties to Macroscale Benefits. ACS nano. 2021;15(3):3646-73.

- Li K, Mcgrady D, Zhao X, Ker D, Tekinalp H, He X, et al. Surface-modified and oven-dried microfibrillated cellulose reinforced biocomposites: Cellulose network enabled high performance. Carbohydrate Polymers. 2021;256:117525.

- Wang L, Li K, Copenhaver K, Mackay S, Lamm ME, Zhao X, et al. Review on Nonconventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications. Biomacromolecules. 2021;22(10):4037-59.

- Peter Kelly, Peng Cheng, Douglas Gardner, William Gramlich, “Aqueous Polymer Modification of Cellulose Nanofibrils by Grafting- Through a Reactive Methacrylate Group” in Macro Molecular Rapid Communications, November 2020.

- Kelly, P. V.; Gardner, D. J.; Gramlich, W. M. “Optimizing lignocellulosic nanofibril dimensions and morphology by mechanical refining for enhanced adhesion.” Carbohydrate Polymers 2021, DOI: 10.1016/j.carbpol.2021.118566

Next-Gen Advanced Manufacturing

Demonstrating innovative, high-feed rate additive manufacturing using AI and High Performance Computing to improve performance and quality.

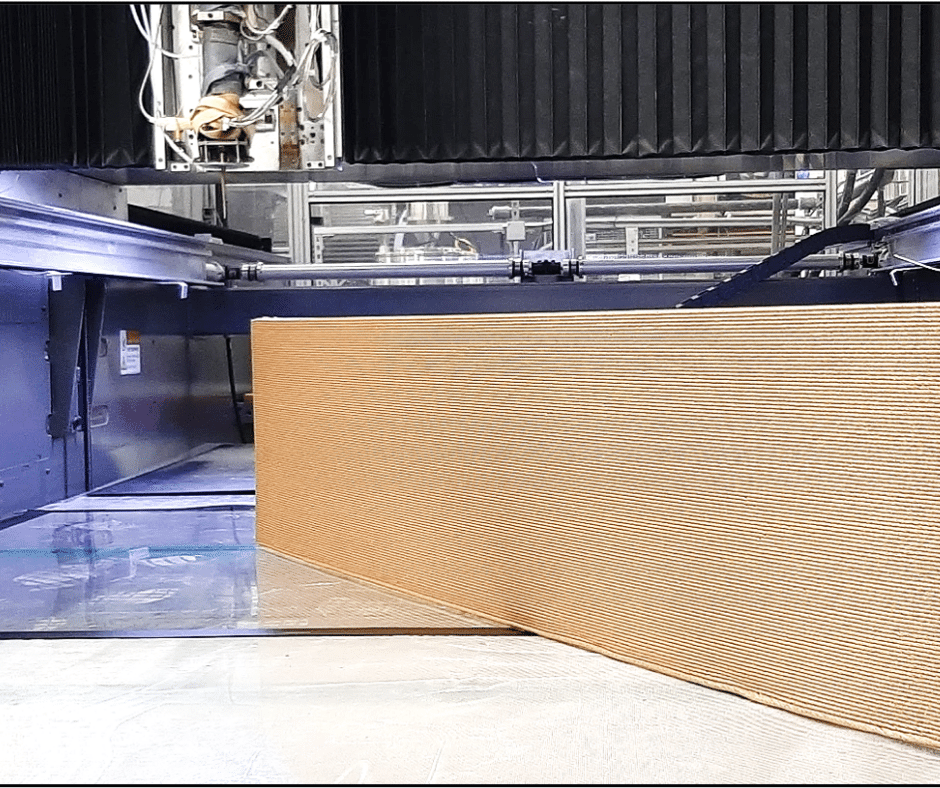

DEFINING THE FUTURE OF LARGE-AREA AM

We are developing the capability to print more than 500 lbs per hour using the world’s largest 3D printer, located at the University of Maine’s Advanced Structures and Composites Center.

ADVANCEMENTS IN ARTIFICIAL INTELLIGENCE

Through advanced and adaptive high performance computing and AI, we are developing autonomous closed loop systems to enable ‘born certified’ 3D printed parts and objects.

INCREASE EFFICIENCY

Our team is developing systems to use multiple extruders in tandem to increase throughput and utilize multi-material 3D printing that has never been demonstrated before.

Major Accomplishments

- Optimized a method to direct print biobased foam which can tune both density and strength of the printed foam material.

- Improved large AM printing by incorporating in-situ sensing with FE modeling to accurately (>95%) predict warpage during printing.

- Continued innovation in large area printers with development of multiplexing extruder head and higher throughput (500lb/hr) extruder head

Related Publications

- Tekinalp HL, Meng X, Lu Y, Kunc V, Love LJ, Peter WH, et al. High modulus biocomposites via additive manufacturing: Cellulose nanofibril networks as “microsponges”. Composites Part B: Engineering. 2019;173:106817.

- Lamm ME, Wang L, Kishore V, Tekinalp H, Kunc V, Wang J, et al. Material extrusion additive manufacturing of wood and lignocellulosic filled composites. Polymers. 2020;12(9):2115.

- Wang L, Gardner DJ, Wang J, Yang Y, Tekinalp HL, Tajvidi M, Ozcan S et al. Towards the scale-up production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships. Composites Part B: Engineering. 2020:108297.

- Bhagia S, Gallego NC, Hiremath N, Harper DP, Lowden RA, Lowden RR, Ozcan S, et al. Fine grinding of thermoplastics by high speed friction grinding assisted by guar gum. Journal of Applied Polymer Science. 2021;138(32):50797.

- Ziabari A, Dubey A, Venkatakrishnan S, Frederick C, Bingham P, Dehoff R, et al. High Resolution X-Ray CT Reconstruction of Additively Manufactured Metal Parts using Generative Adversarial Network-based Domain Adaptation in AI-CT. Microscopy and Microanalysis. 2021;27(S1):2940-2.

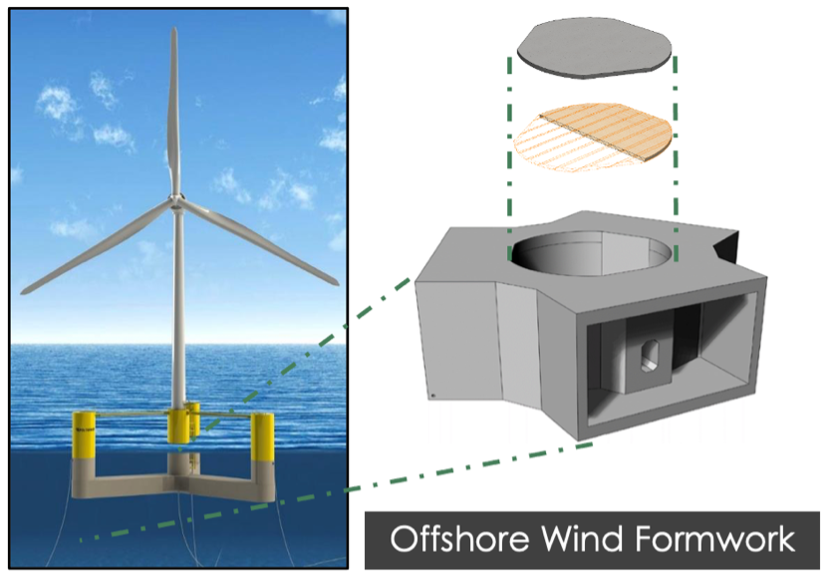

Accelerate Net Zero U.S. Manufacturing

We are working directly with industry to accelerate the U.S. to net zero manufacturing by incorporating our research in sustainable materials in highly efficient, next-gen equipment and processes.

TECHNICAL COLLABORATIONS

Our team is engaged in more than 20 technical collaborations working with industry to apply our research to drive sustainable manufacturing and achieve cost savings. These collaborations showcase real-world, implementable solutions.

WORKFORCE DEVELOPMENT

We work with our partners to identify opportunities to integrate bio-based materials and large area AM in their businesses. The program supports dozens of student researchers in multiple disciplines with research exchange opportunities between the University of Maine and Oak Ridge National Laboratory.

ECONOMIC DEVELOPMENT & STIMULATION

SM2ART is redefining how national laboratories interact with universities and industry to transfer knowledge directly into local economies.

Major Accomplishments

- Achieved >40% reduction in energy consumption used to fibrillate cellulose fibers being incorporated into composites to enhance strength and modulus.

- Developed novel drying methods for reducing the energy needed in drying cellulose materials used for feedstock reinforcement. They each reduce the energy needed to remove water, and several optimize the production of material with nanoscale morphology and high aspect ratio.

Related Publications

- Kooduvalli K, Sharma B, Webb E, Vaidya U, Ozcan S. Sustainability Indicators for Biobased Product Manufacturing: A Systematic Review. Journal of Sustainable Development. 2019;12(1):55-83.

- Zhao X, Tekinalp H, Meng X, Ker D, Benson B, Pu Y, Ozcan S, et al. Poplar as biofiber reinforcement in composites for large-scale 3D printing. ACS Applied Bio Materials. 2019;2(10):4557-70..

- Li M, Pu Y, Thomas VM, Yoo CG, Ozcan S, Deng Y, et al. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Composites Part B: Engineering. 2020:108254.

- Bhagia S, Bornani K, Agarwal R, Satlewal A, Ďurkovič J, Lagaňa R, Ozcan S, et al. Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Applied Materials Today. 2021;24:101078.

- Zhao X, Korey M, Li K, Copenhaver K, Tekinalp H, Celik S, et al. Plastic waste upcycling toward a circular economy. Chemical Engineering Journal. 2021:131928.

- Zhao X, Copenhaver K, Wang L, Korey M, Gardner DJ, Li K, et al. Recycling of natural fiber composites: Challenges and opportunities. Resources, Conservation and Recycling. 2022;177:105962.

Research

Our team of experts is developing and optimizing the production and integration of bio-based materials and next-generation manufacturing systems into mainstream manufacturing to achieve net-zero carbon emissions.

Sustainable Materials Development & Optimization

REDUCE CARBON FOOTPRINT

Our team is at the forefront of developing sustainable materials that cost less and require significantly less energy to produce. For example, we have reduced the energy needed to produce some of these materials by 44%, ruther reducing their carbon footprint by almost half.

HIGH PERFORMANCE BIO-BASED MATERIALS

We are improving the performance of bio-based materials to match or exceed the mechanical properties of similar fossil-fuel derived materials. For example, some of these bio-based composites show significant improvements in tensile strenth and modulus, by 5.4% and 29.8%, compared to traditional materials.

LOWER COST

Through new methods and material innovations, we are creating low cost, sustainable composites that are cost-competitive with traditional materials.

Major Accomplishments

- Designed tailorable water-based chemistries to surface modify cellulose materials and improve biobased composite strength and modulus for specific polymers (PLA, PETg, PBS), these methods are currently being scaled up to produce improved feedstock for 3DP applications.

- Developed new co-spraying methods for producing dry particles of mixed- or coated-cellulose with thermoplastic materials. The thermoplastic-coated cellulose can be directly molded into various products or compounded with other thermoplastic matrices with improved interfacial properties of cellulose, leading to better dispersion/distribution of cellulose in matrices.

Related Publications

- Meng X, Bocharova V, Tekinalp H, Cheng S, Kisliuk A, Sokolov AP, Ozcan S et al. Toughening of nanocelluose/PLA composites via bio-epoxy interaction: Mechanistic study. Materials & Design. 2018;139:188-97.

- Meng X, Nguyen NA, Tekinalp H, Lara-Curzio E, Ozcan S. Supertough PLA-silane nanohybrids by in situ condensation and grafting. ACS Sustainable Chemistry & Engineering. 2018;6(1):1289-98.

- Li K, Skolrood LN, Aytug T, Tekinalp H, Ozcan S. Strong and tough cellulose nanofibrils composite films: Mechanism of synergetic effect of hydrogen bonds and ionic interactions. ACS Sustainable Chemistry & Engineering. 2019;7(17):14341-6.

- Li K, Wang Y, Rowe M, Zhao X, Li T, Tekinalp H, et al. Poly (lactic acid) toughening through chain end engineering. ACS Applied Polymer Materials. 2019;2(2):411-7.

- Li Y, Zhang Y, Goswami M, Vincent D, Wang L, Liu T, Ozcan S, et al. Liquid crystalline networks based on photo-initiated thiol–ene click chemistry. Soft matter. 2020;16(7):1760-70.

- Meng X, Scheidemantle B, Li M, Wang Y-y, Zhao X, Toro-González M, Ozcan S et al. Synthesis, characterization, and utilization of a lignin-based adsorbent for effective removal of azo dye from aqueous solution. ACS omega. 2020;5(6):2865-77.

- Sinquefield S, Ciesielski PN, Li K, Gardner DJ, Ozcan S. Nanocellulose dewatering and drying: current state and future perspectives. ACS Sustainable Chemistry & Engineering. 2020;8(26):9601-15.

- Wang Y, Li K, Zhao X, Tekinalp H, Li T, Ozcan S. Toughening by nanodroplets: Polymer–droplet biocomposite with anomalous toughness. Macromolecules. 2020;53(11):4568-76.

- Zhao X, Li K, Wang Y, Tekinalp H, Larsen G, Rasmussen D, et al. High-strength polylactic acid (PLA) biocomposites reinforced by epoxy-modified pine fibers. ACS Sustainable Chemistry & Engineering. 2020;8(35):13236-47.

- Zhao X, Li K, Wang Y, Tekinalp H, Richard A, Webb E, Ozcan S, et al. Bio-treatment of poplar via amino acid for interface control in biocomposites. Composites Part B: Engineering. 2020;199:108276.

- Bhagia S, Bornani K, Soydan Ozcan D, Ragauskas AJ. Terephthalic Acid Copolyesters Containing Tetramethylcyclobutanediol for High‐Performance Plastics. ChemistryOpen. 2021;10(8):830.

- Cao D, Li Q, Sun X, Wang Y, Zhao X, Cakmak E, et al. Amphipathic Binder Integrating Ultrathin and Highly Ion‐Conductive Sulfide Membrane for Cell‐Level High‐Energy‐Density All‐Solid‐State Batteries. Advanced Materials. 2021:2105505.

- Copenhaver K, Li K, Lamm ME, Walker C, Johnson D, Han Y, et al. Recycled Cardboard Containers as a Low Energy Source for Cellulose Nanofibrils and Their Use in Poly (l-lactide) Nanocomposites. ACS Sustainable Chemistry & Engineering. 2021.

- Lamm ME, Li K, Qian J, Wang L, Lavoine N, Newman R, et al. Cellulose Nanofiber Templating: Recent Advances in Functional Materials through Cellulose Nanofiber Templating (Adv. Mater. 12/2021). Advanced Materials. 2021;33(12):2170094.

- Li K, Clarkson CM, Wang L, Liu Y, Lamm M, Pang Z, et al. Alignment of Cellulose Nanofibers: Harnessing Nanoscale Properties to Macroscale Benefits. ACS nano. 2021;15(3):3646-73.

- Li K, Mcgrady D, Zhao X, Ker D, Tekinalp H, He X, et al. Surface-modified and oven-dried microfibrillated cellulose reinforced biocomposites: Cellulose network enabled high performance. Carbohydrate Polymers. 2021;256:117525.

- Wang L, Li K, Copenhaver K, Mackay S, Lamm ME, Zhao X, et al. Review on Nonconventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications. Biomacromolecules. 2021;22(10):4037-59.

- Peter Kelly, Peng Cheng, Douglas Gardner, William Gramlich, “Aqueous Polymer Modification of Cellulose Nanofibrils by Grafting- Through a Reactive Methacrylate Group” in Macro Molecular Rapid Communications, November 2020.

- Kelly, P. V.; Gardner, D. J.; Gramlich, W. M. “Optimizing lignocellulosic nanofibril dimensions and morphology by mechanical refining for enhanced adhesion.” Carbohydrate Polymers 2021, DOI: 10.1016/j.carbpol.2021.118566

Next-Gen Advanced Manufacturing

DEFINING THE FUTURE OF LARGE-AREA AM

We are developing the capability to print more than 500 lbs per hour using the world’s largest 3D printer, located at the University of Maine’s Advanced Structures and Composites Center.

ADVANCEMENTS IN ARTIFICIAL INTELLIGENCE

Through advanced and adaptive high performance computing and AI, we are developing autonomous closed loop systems to enable ‘born certified’ 3D printed parts and objects.

INCREASE EFFICIENCY

Our team is developing systems to use multiple extruders in tandem to increase throughput and utilize multi-material 3D printing that has never been demonstrated before.

Major Accomplishments

- Optimized a method to direct print biobased foam which can tune both density and strength of the printed foam material.

- Improved large AM printing by incorporating in-situ sensing with FE modeling to accurately (>95%) predict warpage during printing.

- Continued innovation in large area printers with development of multiplexing extruder head and higher throughput (500lb/hr) extruder head

Related Publications

- Tekinalp HL, Meng X, Lu Y, Kunc V, Love LJ, Peter WH, et al. High modulus biocomposites via additive manufacturing: Cellulose nanofibril networks as “microsponges”. Composites Part B: Engineering. 2019;173:106817.

- Lamm ME, Wang L, Kishore V, Tekinalp H, Kunc V, Wang J, et al. Material extrusion additive manufacturing of wood and lignocellulosic filled composites. Polymers. 2020;12(9):2115.

- Wang L, Gardner DJ, Wang J, Yang Y, Tekinalp HL, Tajvidi M, Ozcan S et al. Towards the scale-up production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships. Composites Part B: Engineering. 2020:108297.

- Bhagia S, Gallego NC, Hiremath N, Harper DP, Lowden RA, Lowden RR, Ozcan S, et al. Fine grinding of thermoplastics by high speed friction grinding assisted by guar gum. Journal of Applied Polymer Science. 2021;138(32):50797.

- Ziabari A, Dubey A, Venkatakrishnan S, Frederick C, Bingham P, Dehoff R, et al. High Resolution X-Ray CT Reconstruction of Additively Manufactured Metal Parts using Generative Adversarial Network-based Domain Adaptation in AI-CT. Microscopy and Microanalysis. 2021;27(S1):2940-2.

Accelerate Net Zero U.S. Manufacturing

TECHNICAL COLLABORATIONS

Our team is engaged in more than 20 technical collaborations working with industry to apply our research to drive sustainable manufacturing and achieve cost savings. These collaborations showcase real-world, implementable solutions.

WORKFORCE DEVELOPMENT

We work with our partners to identify opportunities to integrate bio-based materials and large area AM in their businesses. The program supports dozens of student researchers in multiple disciplines with research exchange opportunities between the University of Maine and Oak Ridge National Laboratory.

ECONOMIC DEVELOPMENT & STIMULATION

The Hub & Spoke Program is redefining how national laboratories interact with universities and industry to transfer knowledge directly into local economies.

Major Accomplishments

- Achieved >40% reduction in energy consumption used to fibrillate cellulose fibers being incorporated into composites to enhance strength and modulus.

- Developed novel drying methods for reducing the energy needed in drying cellulose materials used for feedstock reinforcement. They each reduce the energy needed to remove water, and several optimize the production of material with nanoscale morphology and high aspect ratio.

Related Publications

- Kooduvalli K, Sharma B, Webb E, Vaidya U, Ozcan S. Sustainability Indicators for Biobased Product Manufacturing: A Systematic Review. Journal of Sustainable Development. 2019;12(1):55-83.

- Zhao X, Tekinalp H, Meng X, Ker D, Benson B, Pu Y, Ozcan S, et al. Poplar as biofiber reinforcement in composites for large-scale 3D printing. ACS Applied Bio Materials. 2019;2(10):4557-70..

- Li M, Pu Y, Thomas VM, Yoo CG, Ozcan S, Deng Y, et al. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Composites Part B: Engineering. 2020:108254.

- Bhagia S, Bornani K, Agarwal R, Satlewal A, Ďurkovič J, Lagaňa R, Ozcan S, et al. Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Applied Materials Today. 2021;24:101078.

- Zhao X, Korey M, Li K, Copenhaver K, Tekinalp H, Celik S, et al. Plastic waste upcycling toward a circular economy. Chemical Engineering Journal. 2021:131928.

- Zhao X, Copenhaver K, Wang L, Korey M, Gardner DJ, Li K, et al. Recycling of natural fiber composites: Challenges and opportunities. Resources, Conservation and Recycling. 2022;177:105962.

SM2ART Publications

“Towards industrial-scale production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships”

Lu Wang, Douglas J. Gardner, Jinwu Wang, Yingchao Yang, Halil L. Tekinalp, Mehdi Tajvidi, Kai Li, Xianhui Zhao, David J. Neivandt, Yousoo Han, Soydan Ozcan, James Anderson

Composites Part B: Engineering, Vol. 201, November 2020.

Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites

Meghan Lamm, Lu Wang, Vidya Kishore, Halil Tekinalp, Vlastimil Kunc, Jinwu Wang, Douglas Gardner, Soydan Ozcan

Polymers 2020, 12(9), 2115

Aqueous Polymer Modification of Cellulose Nanofibrils by Grafting- Through a Reactive Methacrylate Group

Peter Kelly, Peng Cheng, Douglas Gardner, William Gramlich

Macro Molecular Rapid Communications, November 2020.

High-Strength Polylactic Acid (PLA) Biocomposites Reinforced by Epoxy-Modified Pine Fibers

Xianhui Zhao, Kai Li, Yu Wang, Halil Tekinalp, Greg Larsen, Daniel Rasmussen, Ryan Ginder, Lu Wang, Douglas Gardner, Mehdi Tajvidi, Erin Webb, Soydan Ozcan

ACS Sustainable Chemistry & Engineering” July 2020

The Alignment of Cellulose Nanofibers: Harnessing Nanoscale Properties to Macroscale Benefits.

Li K., Clarkson C.M., Wang L., Liu Y., Lamm M.E., Pang Z., Zhou Y., Tajvidi M., Gardner D.J., Tekinalp H., Hu L., Li T., Ragauskas A.J., Youngblood J.P. and Ozcan S.

ACS Nano. 2021.

Recent advances in functional materials through cellulose nanofiber templating.

Lamm M.E., Li K., Qian J., Wang L., Lavoine N., Newmang R., Gardnerd D.J., Li T., Hu L., Ragauskas A.J. Tekinalp H., Kunca V. and Ozcan S.

Advanced Materials. 2020. DOI: 10.1002/adma.202005538.

A Review on Non- conventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications.

Wang L., Li K., Copenhaver K., MacKay S., Meghan L.E., Zhao X., Dixon B., Wang J., Han Y., Neivandt D., Johnson D.A., Walker C.C., Ozcan S., and Gardner D.J.

Biomacromolecules. 2021.

Recycling of Natural Fiber Composites: Challenges and Opportunities.

Zhao X., Copenhaver K., Wang L., Korey M., Gardner D.J., Li K., Lamm M.E., Kishore V., Bhagia S., Tajvidi M., Tekinalp H., Oyedeji O., Wasti S., Webb E., Ragauskas A., Zhu H., William P. and Ozcan S.

Resources, Conservation & Recycling. 2021.

Recycled Cardboard Containers as a Low Energy Source for Cellulose Nanofibrils and Their Use in Polylactic Acid Nanocomposites.

Copenhaver K., Li K., Lamm M., Walker C., Johnson D., Han Y., Wang L., Zhao X., Pu Y., Hinton H., Tekinalp H., Bhagia S., Ragauskas A., Gardner D.J., Ozcan S.

ACS Sustainable Chemistry & Engineering. 2021.

Optimizing lignocellulosic nanofibril dimensions and morphology by mechanical refining for enhanced adhesion.

Kelly, P. V.; Gardner, D. J.; Gramlich, W. M.

Carbohydrate Polymers 2021, DOI: 10.1016/j.carbpol.2021.118566

Toughening of nanocelluose/PLA composites via bio-epoxy interaction: Mechanistic study

Meng X, Bocharova V, Tekinalp H, Cheng S, Kisliuk A, Sokolov AP, Ozcan S et al

Materials & Design. 2018;139:188-97

Synthesis, characterization, and utilization of a lignin-based adsorbent for effective removal of azo dye from aqueous solution

Meng X, Scheidemantle B, Li M, Wang Y-y, Zhao X, Toro-González M, Ozcan S et al.

ACS omega.

Supertough PLA-silane nanohybrids by in situ condensation and grafting.

Meng X, Nguyen NA, Tekinalp H, Lara-Curzio E, Ozcan S. Supertough

ACS Sustainable Chemistry & Engineering. 2018;6(1):1289-98

Sustainability Indicators for Biobased Product Manufacturing: A Systematic Review

Kooduvalli K, Sharma B, Webb E, Vaidya U, Ozcan S.

Journal of Sustainable Development. 2019;12(1):55-83

Strong and tough cellulose nanofibrils composite films: Mechanism of synergetic effect of hydrogen bonds and ionic interactions

Li K, Skolrood LN, Aytug T, Tekinalp H, Ozcan S

ACS Sustainable Chemistry & Engineering. 2019;7(17):14341-6

Poly (lactic acid) toughening through chain end engineering

Li K, Wang Y, Rowe M, Zhao X, Li T, Tekinalp H, et al.

ACS Applied Polymer Materials. 2019;2(2):411-7

High modulus biocomposites via additive manufacturing: Cellulose nanofibril networks as “microsponges”

Kelly, P. V.; Gardner, D. J.; Gramlich, W. M.

Composites Part B: Engineering. 2019;173:106817

Poplar as biofiber reinforcement in composites for large-scale 3D printing

Zhao X, Tekinalp H, Meng X, Ker D, Benson B, Pu Y, Ozcan S, et al.

ACS Applied Bio Materials. 2019;2(10):4557-70

Material extrusion additive manufacturing of wood and lignocellulosic filled composites.

Lamm ME, Wang L, Kishore V, Tekinalp H, Kunc V, Wang J, et al.

Polymers. 2020;12(9):2115

Recent advancements of plant-based natural fiber–reinforced composites and their applications

Li M, Pu Y, Thomas VM, Yoo CG, Ozcan S, Deng Y, et al.

Composites Part B: Engineering. 2020:108254

Nanocellulose dewatering and drying: current state and future perspectives.

Sinquefield S, Ciesielski PN, Li K, Gardner DJ, Ozcan S.

ACS Sustainable Chemistry & Engineering. 2020;8(26):9601-15.

Towards the scale-up production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships.

Wang Y, Li K, Zhao X, Tekinalp H, Li T, Ozcan S.

Macromolecules. 2020;53(11):4568-76.

Bio-treatment of poplar via amino acid for interface control in biocomposites.

Zhao X, Li K, Wang Y, Tekinalp H, Richard A, Webb E, Ozcan S, et al

Composites Part B: Engineering.

Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries.

Bhagia S, Bornani K, Agarwal R, Satlewal A, Ďurkovič J, Lagaňa R, Ozcan S, et al.

Applied Materials Today. 2021;24:101078.

Terephthalic Acid Copolyesters Containing Tetramethylcyclobutanediol for High‐Performance Plastics.

Bhagia S, Bornani K, Soydan Ozcan D, Ragauskas AJ.

ChemistryOpen. 2021;10(8):830.

Fine grinding of thermoplastics by high speed friction grinding assisted by guar gum.

Bhagia S, Gallego NC, Hiremath N, Harper DP, Lowden RA, Lowden RR, Ozcan S, et al.

Journal of Applied Polymer Science. 2021;138(32):50797.

Amphipathic Binder Integrating Ultrathin and Highly Ion‐Conductive Sulfide Membrane for Cell‐Level High‐Energy‐Density All‐Solid‐State Batteries.

Cao D, Li Q, Sun X, Wang Y, Zhao X, Cakmak E, et al.

Advanced Materials. 2021:2105505.

Recycled Cardboard Containers as a Low Energy Source for Cellulose Nanofibrils and Their Use in Poly (l-lactide) Nanocomposites.

Copenhaver K, Li K, Lamm ME, Walker C, Johnson D, Han Y, et al.

ACS Sustainable Chemistry & Engineering. 2021.

Alignment of Cellulose Nanofibers: Harnessing Nanoscale Properties to Macroscale Benefits.

Li K, Clarkson CM, Wang L, Liu Y, Lamm M, Pang Z, et al.

ACS nano. 2021;15(3):3646-73.

Surface-modified and oven-dried microfibrillated cellulose reinforced biocomposites: Cellulose network enabled high performance.

Li K, Mcgrady D, Zhao X, Ker D, Tekinalp H, He X, et al.

Carbohydrate Polymers. 2021;256:117525.

Review on Nonconventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications.

Wang L, Li K, Copenhaver K, Mackay S, Lamm ME, Zhao X, et al.

Biomacromolecules. 2021;22(10):4037-59.

Plastic waste upcycling toward a circular economy.

Zhao X, Korey M, Li K, Copenhaver K, Tekinalp H, Celik S, et al.

Chemical Engineering Journal. 2021:131928.

High Resolution X-Ray CT Reconstruction of Additively Manufactured Metal Parts using Generative Adversarial Network-based Domain Adaptation in AI-CT.

Ziabari A, Dubey A, Venkatakrishnan S, Frederick C, Bingham P, Dehoff R, et al.

Microscopy and Microanalysis. 2021;27(S1):2940-2.

Plastic waste upcycling toward a circular economy.

Zhao X, Korey M, Li K, Copenhaver K, Tekinalp H, Celik S, et al.

Chemical Engineering Journal. 2021:131928.

All SM2ART Publications

“Towards industrial-scale production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships”

Lu Wang, Douglas J. Gardner, Jinwu Wang, Yingchao Yang, Halil L. Tekinalp, Mehdi Tajvidi, Kai Li, Xianhui Zhao, David J. Neivandt, Yousoo Han, Soydan Ozcan, James Anderson

Composites Part B: Engineering, Vol. 201, November 2020.

Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites

Meghan Lamm, Lu Wang, Vidya Kishore, Halil Tekinalp, Vlastimil Kunc, Jinwu Wang, Douglas Gardner, Soydan Ozcan

Polymers 2020, 12(9), 2115

Aqueous Polymer Modification of Cellulose Nanofibrils by Grafting- Through a Reactive Methacrylate Group

Peter Kelly, Peng Cheng, Douglas Gardner, William Gramlich

Macro Molecular Rapid Communications, November 2020.

High-Strength Polylactic Acid (PLA) Biocomposites Reinforced by Epoxy-Modified Pine Fibers

Xianhui Zhao, Kai Li, Yu Wang, Halil Tekinalp, Greg Larsen, Daniel Rasmussen, Ryan Ginder, Lu Wang, Douglas Gardner, Mehdi Tajvidi, Erin Webb, Soydan Ozcan

ACS Sustainable Chemistry & Engineering” July 2020

The Alignment of Cellulose Nanofibers: Harnessing Nanoscale Properties to Macroscale Benefits.

Li K., Clarkson C.M., Wang L., Liu Y., Lamm M.E., Pang Z., Zhou Y., Tajvidi M., Gardner D.J., Tekinalp H., Hu L., Li T., Ragauskas A.J., Youngblood J.P. and Ozcan S.

ACS Nano. 2021.

Recent advances in functional materials through cellulose nanofiber templating.

Lamm M.E., Li K., Qian J., Wang L., Lavoine N., Newmang R., Gardnerd D.J., Li T., Hu L., Ragauskas A.J. Tekinalp H., Kunca V. and Ozcan S.

Advanced Materials. 2020. DOI: 10.1002/adma.202005538.

A Review on Non- conventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications.

Wang L., Li K., Copenhaver K., MacKay S., Meghan L.E., Zhao X., Dixon B., Wang J., Han Y., Neivandt D., Johnson D.A., Walker C.C., Ozcan S., and Gardner D.J.

Biomacromolecules. 2021.

Recycling of Natural Fiber Composites: Challenges and Opportunities.

Zhao X., Copenhaver K., Wang L., Korey M., Gardner D.J., Li K., Lamm M.E., Kishore V., Bhagia S., Tajvidi M., Tekinalp H., Oyedeji O., Wasti S., Webb E., Ragauskas A., Zhu H., William P. and Ozcan S.

Resources, Conservation & Recycling. 2021.

Recycled Cardboard Containers as a Low Energy Source for Cellulose Nanofibrils and Their Use in Polylactic Acid Nanocomposites.

Copenhaver K., Li K., Lamm M., Walker C., Johnson D., Han Y., Wang L., Zhao X., Pu Y., Hinton H., Tekinalp H., Bhagia S., Ragauskas A., Gardner D.J., Ozcan S.

ACS Sustainable Chemistry & Engineering. 2021.

Optimizing lignocellulosic nanofibril dimensions and morphology by mechanical refining for enhanced adhesion.

Kelly, P. V.; Gardner, D. J.; Gramlich, W. M.

Carbohydrate Polymers 2021, DOI: 10.1016/j.carbpol.2021.118566

Toughening of nanocelluose/PLA composites via bio-epoxy interaction: Mechanistic study

Meng X, Bocharova V, Tekinalp H, Cheng S, Kisliuk A, Sokolov AP, Ozcan S et al

Materials & Design. 2018;139:188-97

Synthesis, characterization, and utilization of a lignin-based adsorbent for effective removal of azo dye from aqueous solution

Meng X, Scheidemantle B, Li M, Wang Y-y, Zhao X, Toro-González M, Ozcan S et al.

ACS omega.

Supertough PLA-silane nanohybrids by in situ condensation and grafting.

Meng X, Nguyen NA, Tekinalp H, Lara-Curzio E, Ozcan S. Supertough

ACS Sustainable Chemistry & Engineering. 2018;6(1):1289-98

Sustainability Indicators for Biobased Product Manufacturing: A Systematic Review

Kooduvalli K, Sharma B, Webb E, Vaidya U, Ozcan S.

Journal of Sustainable Development. 2019;12(1):55-83

Strong and tough cellulose nanofibrils composite films: Mechanism of synergetic effect of hydrogen bonds and ionic interactions

Li K, Skolrood LN, Aytug T, Tekinalp H, Ozcan S

ACS Sustainable Chemistry & Engineering. 2019;7(17):14341-6

Poly (lactic acid) toughening through chain end engineering

Li K, Wang Y, Rowe M, Zhao X, Li T, Tekinalp H, et al.

ACS Applied Polymer Materials. 2019;2(2):411-7

High modulus biocomposites via additive manufacturing: Cellulose nanofibril networks as “microsponges”

Kelly, P. V.; Gardner, D. J.; Gramlich, W. M.

Composites Part B: Engineering. 2019;173:106817

Poplar as biofiber reinforcement in composites for large-scale 3D printing

Zhao X, Tekinalp H, Meng X, Ker D, Benson B, Pu Y, Ozcan S, et al.

ACS Applied Bio Materials. 2019;2(10):4557-70

Material extrusion additive manufacturing of wood and lignocellulosic filled composites.

Lamm ME, Wang L, Kishore V, Tekinalp H, Kunc V, Wang J, et al.

Polymers. 2020;12(9):2115

Recent advancements of plant-based natural fiber–reinforced composites and their applications

Li M, Pu Y, Thomas VM, Yoo CG, Ozcan S, Deng Y, et al.

Composites Part B: Engineering. 2020:108254

Nanocellulose dewatering and drying: current state and future perspectives.

Sinquefield S, Ciesielski PN, Li K, Gardner DJ, Ozcan S.

ACS Sustainable Chemistry & Engineering. 2020;8(26):9601-15.

Towards the scale-up production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships.

Wang Y, Li K, Zhao X, Tekinalp H, Li T, Ozcan S.

Macromolecules. 2020;53(11):4568-76.

Bio-treatment of poplar via amino acid for interface control in biocomposites.

Zhao X, Li K, Wang Y, Tekinalp H, Richard A, Webb E, Ozcan S, et al

Composites Part B: Engineering.

Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries.

Bhagia S, Bornani K, Agarwal R, Satlewal A, Ďurkovič J, Lagaňa R, Ozcan S, et al.

Applied Materials Today. 2021;24:101078.

Terephthalic Acid Copolyesters Containing Tetramethylcyclobutanediol for High‐Performance Plastics.

Bhagia S, Bornani K, Soydan Ozcan D, Ragauskas AJ.

ChemistryOpen. 2021;10(8):830.

Fine grinding of thermoplastics by high speed friction grinding assisted by guar gum.

Bhagia S, Gallego NC, Hiremath N, Harper DP, Lowden RA, Lowden RR, Ozcan S, et al.

Journal of Applied Polymer Science. 2021;138(32):50797.

Amphipathic Binder Integrating Ultrathin and Highly Ion‐Conductive Sulfide Membrane for Cell‐Level High‐Energy‐Density All‐Solid‐State Batteries.

Cao D, Li Q, Sun X, Wang Y, Zhao X, Cakmak E, et al.

Advanced Materials. 2021:2105505.

Recycled Cardboard Containers as a Low Energy Source for Cellulose Nanofibrils and Their Use in Poly (l-lactide) Nanocomposites.

Copenhaver K, Li K, Lamm ME, Walker C, Johnson D, Han Y, et al.

ACS Sustainable Chemistry & Engineering. 2021.

Alignment of Cellulose Nanofibers: Harnessing Nanoscale Properties to Macroscale Benefits.

Li K, Clarkson CM, Wang L, Liu Y, Lamm M, Pang Z, et al.

ACS nano. 2021;15(3):3646-73.

Surface-modified and oven-dried microfibrillated cellulose reinforced biocomposites: Cellulose network enabled high performance.

Li K, Mcgrady D, Zhao X, Ker D, Tekinalp H, He X, et al.

Carbohydrate Polymers. 2021;256:117525.

Review on Nonconventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications.

Wang L, Li K, Copenhaver K, Mackay S, Lamm ME, Zhao X, et al.

Biomacromolecules. 2021;22(10):4037-59.

Plastic waste upcycling toward a circular economy.

Zhao X, Korey M, Li K, Copenhaver K, Tekinalp H, Celik S, et al.

Chemical Engineering Journal. 2021:131928.

High Resolution X-Ray CT Reconstruction of Additively Manufactured Metal Parts using Generative Adversarial Network-based Domain Adaptation in AI-CT.

Ziabari A, Dubey A, Venkatakrishnan S, Frederick C, Bingham P, Dehoff R, et al.

Microscopy and Microanalysis. 2021;27(S1):2940-2.

Plastic waste upcycling toward a circular economy.

Zhao X, Korey M, Li K, Copenhaver K, Tekinalp H, Celik S, et al.

Chemical Engineering Journal. 2021:131928.