AMC awarded $2.5M to upgrade equipment, accelerate additive metal manufacturing

The Advanced Manufacturing Center at the University of Maine has been awarded two grants totaling $2.5 million to upgrade its equipment and accelerate the adoption of additive metal manufacturing in the state.

The Maine Manufacturing Extension Partnership (Maine MEP) received a $1 million National Institute of Standards and Technology (NIST) Manufacturing Extension Partnership (MEP) Competitive Awards Program grant to support and enhance the AMC’s Center for Additive Manufacturing of Metals.

The AMC also was awarded $1.5 million for equipment upgrades to better meet the needs of industry partners and the state’s workforce. The improvements will enable the center to build resilience into the state’s manufacturing businesses by providing access to new technology, as well as innovative technical assistance.

The funding includes a $750,000 investment from the U.S. Economic Development Administration (EDA). Matching funds come from UMaine’s Office of the Vice President for Research and College of Engineering, as well as the Maine Technology Institute (MTI).

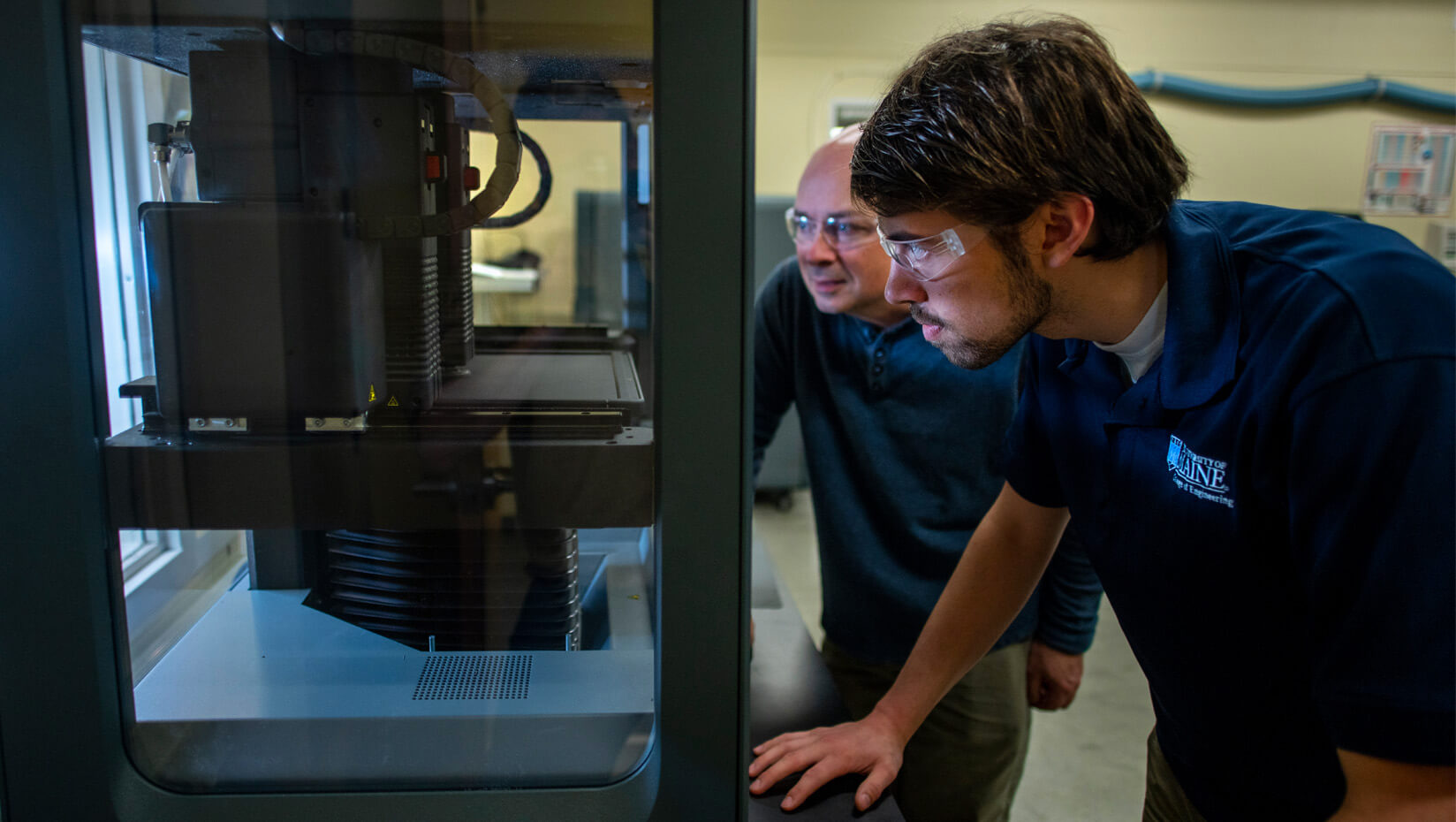

The purchase and installation of state-of-the-art additive and subtractive manufacturing equipment will give the AMC the capabilities current manufacturing R&D demands while increasing efficiency, according to John Belding, AMC director.

“Learning on the latest technology is critical to our students and industry workforce development; if we can assist companies to adopt the latest technology without risk, it will be a huge win for the entire state of Maine,” he says.

The new equipment will be unique to the state and publicly available to entrepreneurs, businesses and their employees, Belding says, adding the technology will likely attract out-of-state companies, as well.

The upgrades include a Desktop Metal FDM additive metal machine with testing equipment, 5-axis machining center, hybrid metal additive cell, wire EDM (electrical discharge machining), and 4-axis lathe with live tooling.

The project team will focus on incorporating new technology into current projects as well as more broadly communicating the capabilities of emerging additive metal technology in a variety of manufacturing types, including timber harvesting and processing, food and beverage manufacturing, and medical and aerospace.

“This EDA investment will help obtain vital supplies needed to serve Maine’s manufacturing industry and accommodate its future growth,” U.S. Assistant Secretary of Commerce for Economic Development John Fleming said in an EDA news release.

Funding from MTI was used as a partial match to develop the Center for Additive Manufacturing of Metals (CAMM), which offers additive metal manufacturing services and training to businesses. The center focuses on the process of fusing small metal particles together through 3D printing to form solid metal objects.

The collaboration between Maine MEP and AMC aims to accelerate the adoption of additive metal manufacturing in the state.

“Additive metal manufacturing represents an epochal shift in manufacturing technology on par with the advent of multi-axis machining in the 1980s,” says Larry Robinson, president of the Maine MEP. “This grant will train the next generation of designers and engineers on how to effectively utilize this new technology.”

The adoption of game-changing technology such as additive metals manufacturing represents the classic chicken-or-the-egg dilemma, according to Robinson.

“In order for the technology to become widely adopted, there has to be a nascent infrastructure to scale from,” he says, adding the grant is designed to facilitate wide adoption of the emerging technology.

To develop state and regional capacity in the area of additive manufacturing, the project aims to build upon and enhance CAMM by funding additional measurement and laser manufacturing equipment at the AMC.

The initiative, which aligns with the University of Maine System “Research and Development Plan,” also aims to complete more than 30 industry projects and educate 150 companies about additive manufacturing within the three-year period; develop outreach materials and host knowledge-sharing events; engage the NIST MEP National Network, specifically the five additional centers in New England; and contribute to the sustainable development of additive manufacturing capacity in Maine.

“This award will allow the AMC and Maine MEP to keep current with the ever-expanding technology and training needs of manufacturers in the state,” Belding says.

Maine MEP is a public-private partnership and an affiliate NIST under the U.S. Department of Commerce. It facilitates economic development in Maine by delivering technical services and workforce training solutions to Maine’s small manufacturers.

As part of the College of Engineering, AMC links UMaine’s education and research with the university’s active industrial support and economic development programs. The center is readily accessible to businesses, entrepreneurs and researchers in Maine and throughout the country.

Contact: Elyse Catalina, 207.581.3747, elyse.catalina@maine.edu