Center offering additive metal manufacturing services, training to Maine businesses

A center at the University of Maine is offering additive metal manufacturing services and training to facilitate the adoption of 3D metal printing in businesses around the state.

The Center for Additive Manufacturing of Metals (CAMM), based at the Advanced Manufacturing Center (AMC) on the Orono campus, focuses on the process of fusing small metal particles together through 3D printing to form solid metal objects.

The bound metal-deposition modeling process is ideal for small parts used in tooling or fixturing.

Funding for the center comes from a nearly $500,000 Maine Technology Institute (MTI) cluster initiative program grant, with matching funds from the university and 35 Maine companies, bringing the total to $1 million. The funds also will be used as a partial match for a $750,000 U.S. Economic Development Administration grant AMC recently received. With matching funds, the grant totals $1.5 million.

CAMM is working with the partner companies, including GE Power in Bangor and Pratt & Whitney in North Berwick, to produce parts, as well as test and conduct research on the process.

The center is training company personnel as well as UMaine staff and students on the new technology, and is the only Maine facility currently offering these services. CAMM, which has been in a pilot phase for the past two months, recently was awarded “Innovator of the Year” at the Manufacturers Association of Maine’s annual summit. The initiative aligns with the University of Maine System “Research and Development Plan.”

“We’re helping to further the technology and taking the risk away for companies,” says John Belding, AMC director. “We can work with them on the training, the design, the research aspect of making the parts.”

By using CAMM services, companies can create a product and realize the potential of adding the technology to their facility before spending $200,000 on a new machine.

“The goal is to at least disseminate the technology and get it out there in the field where people are interested and want to use it,” Belding says.

Additive metal manufacturing, which produces little wasted material, is a more advanced and cost-effective process than subtractive manufacturing, where you take away material to create parts, according to Belding.

“There are tons of Maine companies that have a plastic 3D printer that they use for different tools and fixtures. When they make a part out of plastic, sometimes they need to turn around and make it again out of metal so they can use it in the production process. With CAMM, we skip that whole plastic step and go directly to metal parts that can be used in production,” says Belding, who adds that more can be done with metal products with little difference in price.

The 3D metal printing process can be used in a variety of ways, including creating prototypes and fixtures that are needed to make other parts, such as a piece to hold a part in place to apply a coating, numbering system or machining, Belding says.

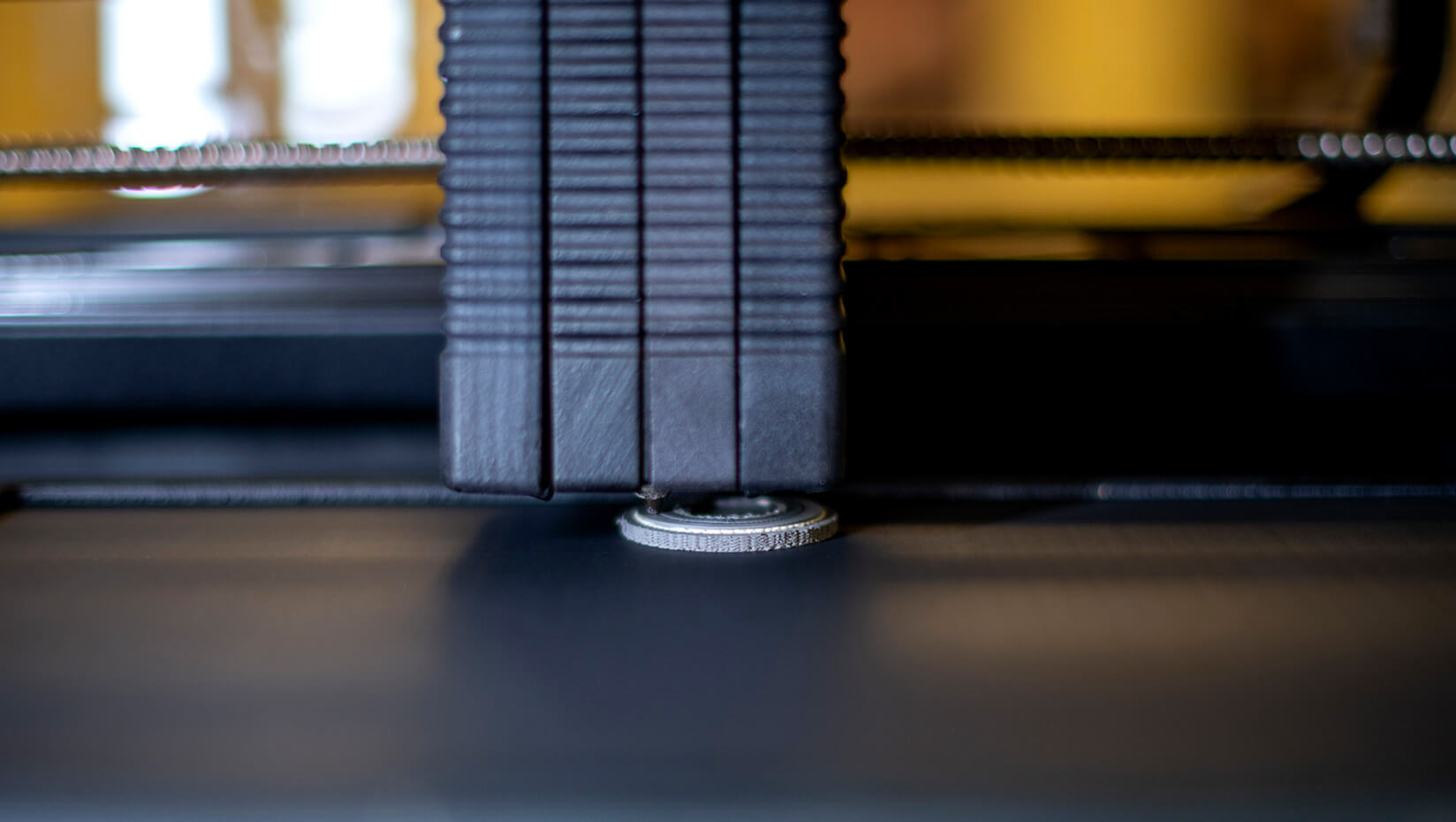

A system of three machines at CAMM uses metal powder mixed with wax and a polymer binder to create structures that have similar properties to metal parts produced via casting or subtractive processes such as milling or turning.

The powder and binder mix, called Bound Metal Deposition, is packaged in sticks, similar to hot glue, and is extruded layer by layer from a 3D printer in a pattern that represents the part that will be manufactured.

From there, the part goes into a debinding machine to remove the wax.

It is then finished in a vacuum furnace that gets up to 2,500 degrees F. The furnace shrinks the material by 20 percent and consolidates the part into a 98.9 percent solid piece, according to Belding.

While it can take up to a week to create a part, according to Belding, there is no tooling or machining involved, and several parts can be made at once.

The Studio System machines come from Desktop Metal, a startup out of Burlington, Mass.

“A lot of the technology is happening outside the state in the Northeast,” Belding says. “We see our mission as to really help Maine raise the bar and come up to speed in additive metal manufacturing.”

CAMM is located in the AMC, an engineering support and service center that is dedicated to promoting economic development in the state and beyond.

As part of the College of Engineering, AMC links UMaine’s education and research with the university’s active industrial support and economic development programs.

Contact: Elyse Catalina, 207.581.3747, elyse.catalina@maine.edu