2012 Green Team

The Green Team

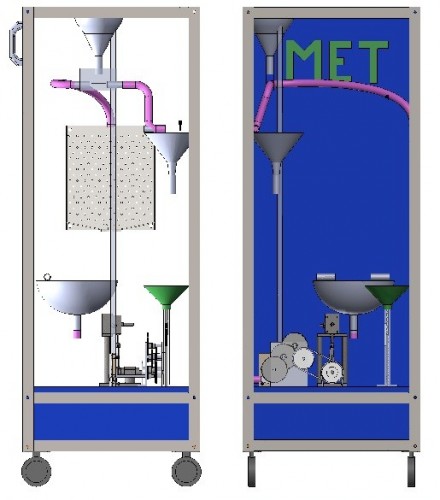

The objective for the Green team is to design and build a kinetic structure that is visually appealing to people who are not generally drawn to mechanical engineering technology by showing what is covered in the curriculum over the four years in the course. The structure should be easy for one person to move and set up in a short amount of time.

_________________________________________________________________________________________________

Members of the green team:

Hometown: Brewer, Maine

Garrett graduated from Brewer High School in 2008 and is currently in his fourth year at the University of Maine Orono majoring in Mechanical Engineering Technology and will graduate in May of 2012. His hobbies include snowmobiling, trucks and welding.

Hometown: Lincolnville, Maine

Jake graduated from Camden Hills Regional High School in 2008. He is currently in his fourth year majoring in Mechanical Engineering Technology and will graduate in May 2012. His hobbies include four wheeling, snowmobiling, and hunting.

Hometown: Bucksport, Maine

Jon graduated from Bucksport High School in 2008 and is currently attending the University of Maine Orono majoring in Mechanical Engineering Technology and is graduating in May 2012. His hobbies include fishing, hunting and snowmobiling.

Hometown: Windham, Maine

Zach graduated from Windham High School in the class of 2008. He is currently majoring in Mechanical Engineering Technology and will graduate in May of 2012. His hobbies include snowmobiling, snowboarding, and carpentry.

Hometown: Abington, Massachusetts

Emily graduated from Abington High School in 2008. She is in her fourth year at the University of Maine Orono majoring in Mechanical Engineering Technology, graduating in May 2012. She is currently the president of the University’s Society of Women Engineers section. Her hobbies include shopping, waterskiing and swimming.

_____________________________________________________________________________________

About our design:

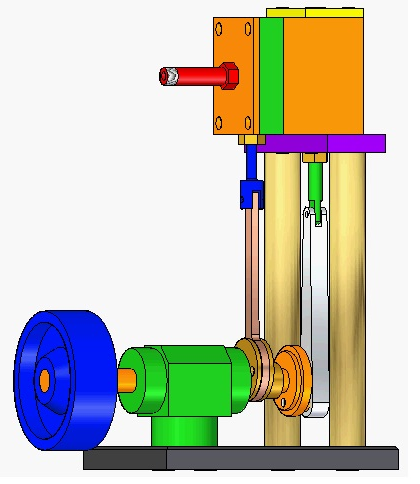

The main feature of our kinetic structure will be our steam engine that was designed and built by all First Year MET students.

See the steam engine in motion, courtesy of Professor David Morrison!

See the steam engine in motion, courtesy of Professor David Morrison!

Design Specifications:

- Needs to be eye catching for people passing by the table

- Portable: Must be able to be transported by one person

- Must fit inside designated area for presentations

- Max weight of total structure: 125 pounds

- Needs to be interactive

- Enclosed in Plexiglas for safety reasons

- Stable design (evenly distributed weight)

- Material cost: $1,000 or less

- Moving components (Total of 5 kinetic features)

- Mechanical Components

- Maine theme: Mechanical Engineering Technology

Customer Requests: These are the requests of our customer, Professor David Morrison

- Needs to be eye catching: Grab the attention of people passing and have them stop to ask questions.

- It must show what MET students do in the four year curriculum

- Must be able to fit in a vehicle to be transported

- No larger than (60” H x 24” W x 24” L)

- Contain abstract artwork

- Noise volume of the structure should be minimal

- 120 volt power

- Leave a space for a monitor to be mounted inside the structure

Benchmarking:

- Gears to move marble lifter: We plan on having our ball lifter be moved by gears which will be conntected to the motor.

- T-shape course changer: When the marbles reach the top we want to make sure that they all don’t follow the same path. The way the marbles switch tracks is much like what we will use.

- Plinko Board: To include randomness we are adding a plinko board much like the one in the video

- Marble Lifter: we found a way to make sure that we can lift the marbles up the tube without going too fast or too slow

- Follow the weekly process of building the structure, including testing done, and mock ups of parts.

- Parts that we will be using can be found on our Bill of materials

- Keep updated with our Task Schedule to see when we plan to complete tasks and when we actually complete them.

Brainstorming:

- For detailed drawings of our design like the one below, Click Here!

We would like to thank our sponsor, Mike Gardner at Lane Supply

We would like to thank our sponsor, Mike Gardner at Lane Supply